Chain tooth type continuous wall trenching machine

A grooving machine and chain cutter technology, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of increasing the failure rate of chain cutter type diaphragm wall grooving machine, cumbersome structure layout, and low wire rope life. Easy to popularize and apply, simple in structure, safe and efficient in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

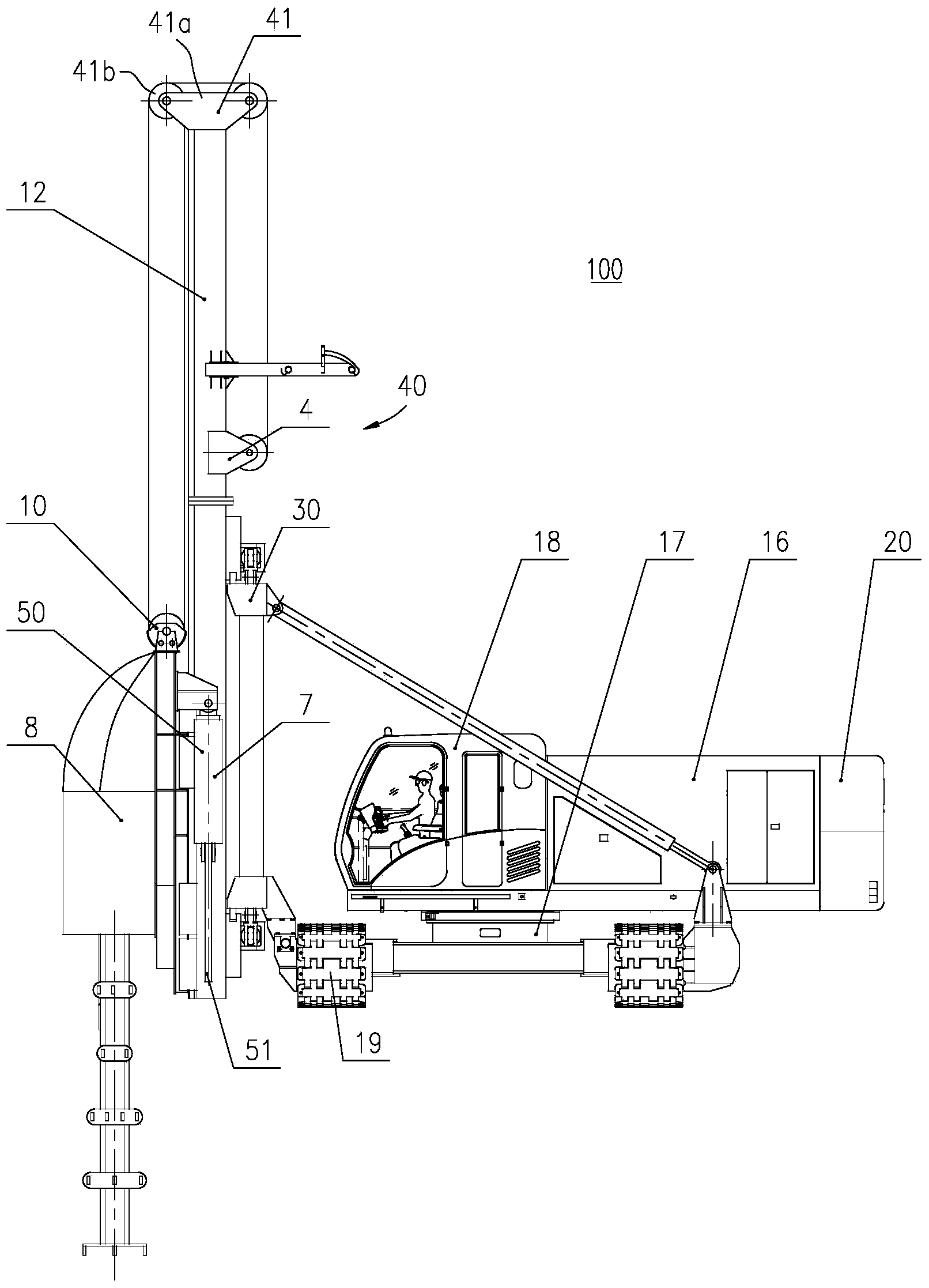

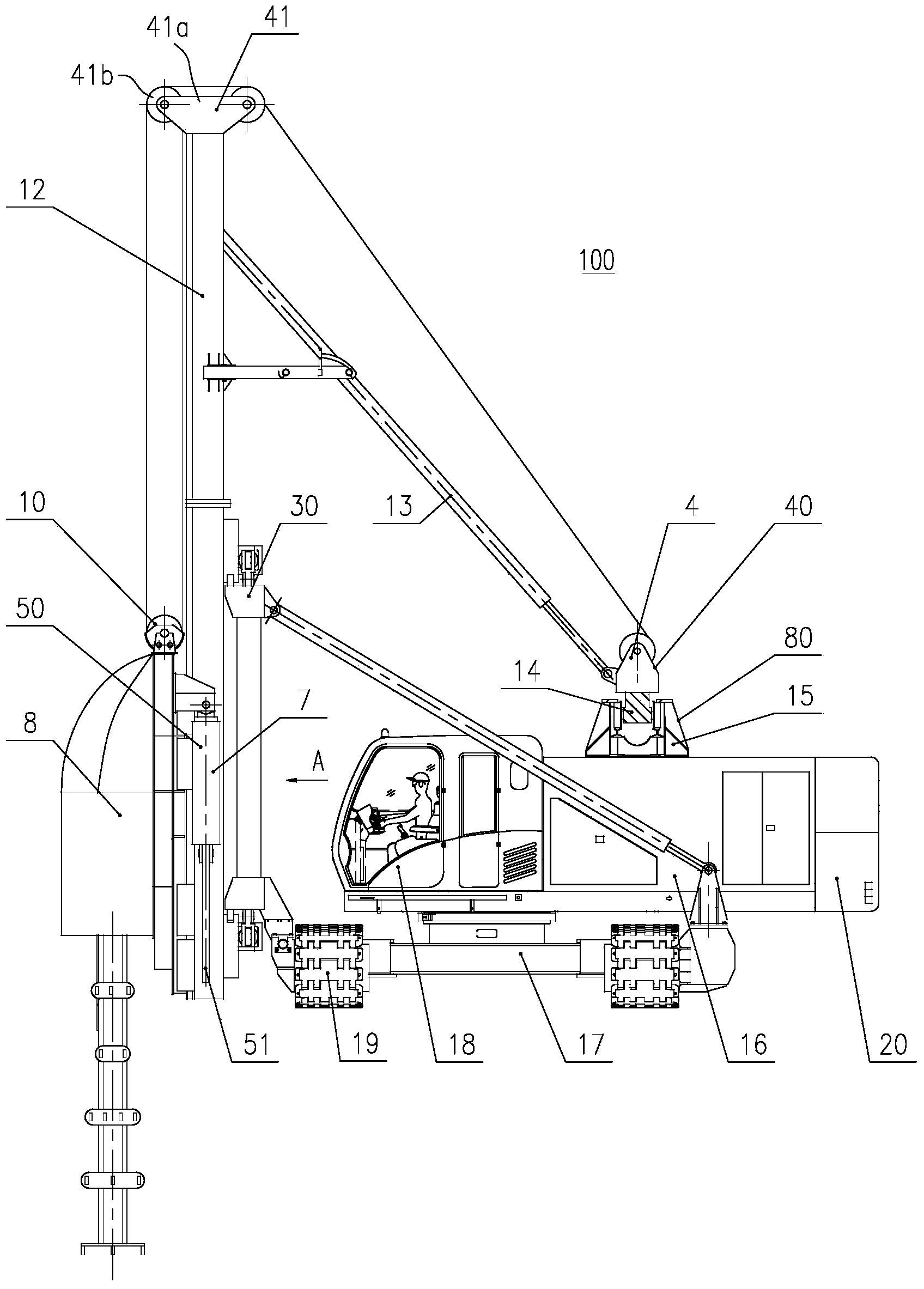

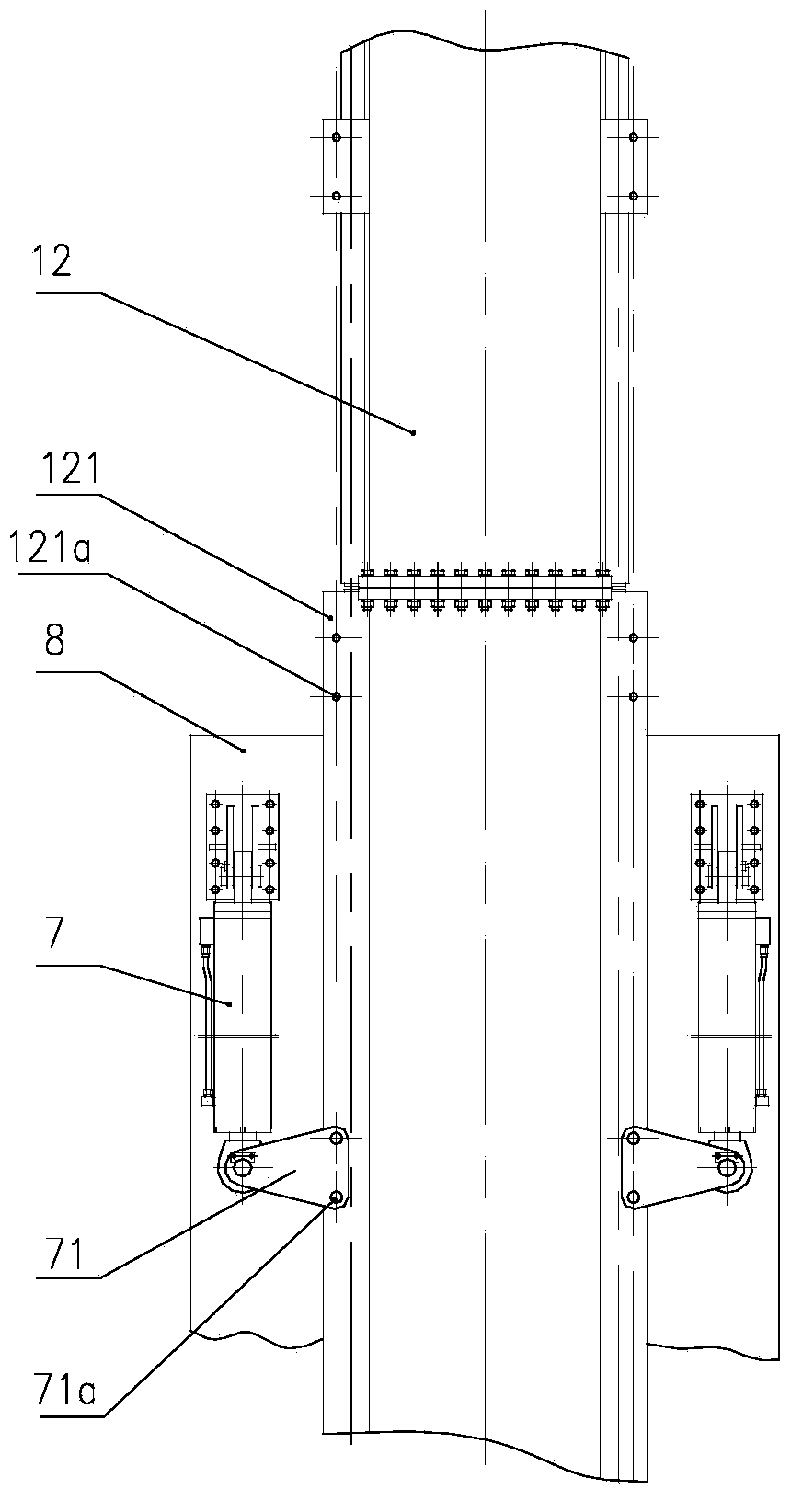

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] figure 1 Shown is the chain cutter type diaphragm wall groove forming machine 100 according to the present invention, which is mainly applied to the continuous wall construction method under cement soil with equal thickness, excavating a groove-shaped cavity with a fixed width and depth in the soil layer or rock-soil layer and synchronously grouting, Thereby forming a continuous wall underground. The chain knife type continuous wall groove forming machine 100 includes a groove forming machine main body 20 . The groover body 20 may include a movable chassis 17 , a cab 18 and a workstation 16 . Wherein, the movable chassis 17, the driver's cab 18 and the workstation 16 are all well known to those skilled in the art, and will not be described in detail here.

[0023] In this application, the front is defined as the forward direction facing the cab 17; the rear is def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com