A microbubble drag reducing pipeline

A micro-bubble and pipeline technology, applied in the direction of pipe elements, pipes/pipe joints/pipes, fluid flow, etc., can solve problems such as large frictional resistance, and achieve the effect of increasing drag reduction rate, increasing fluid velocity, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

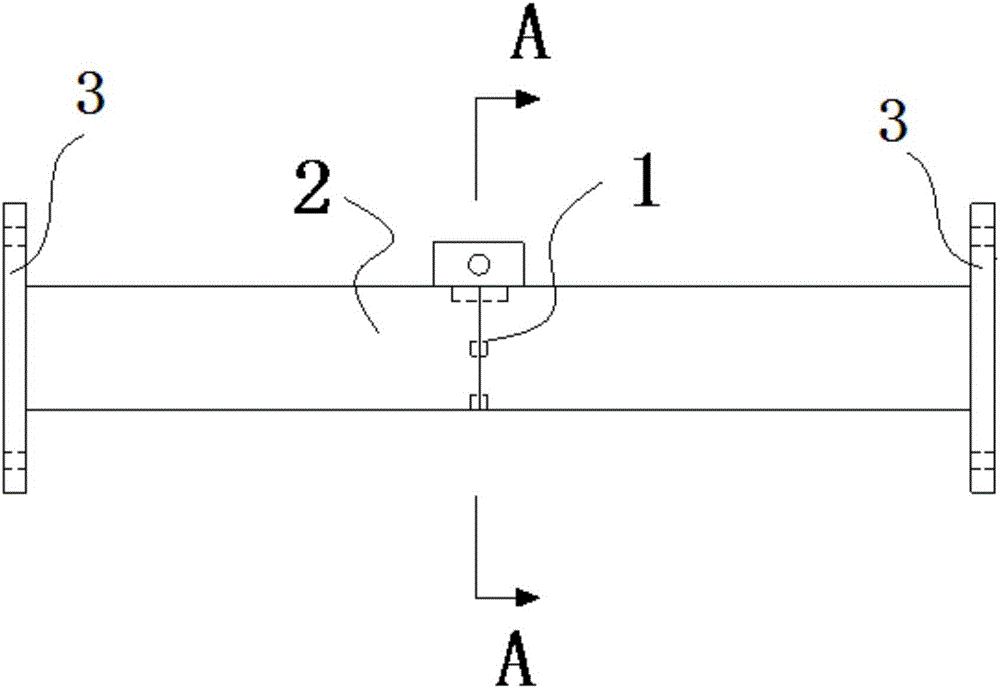

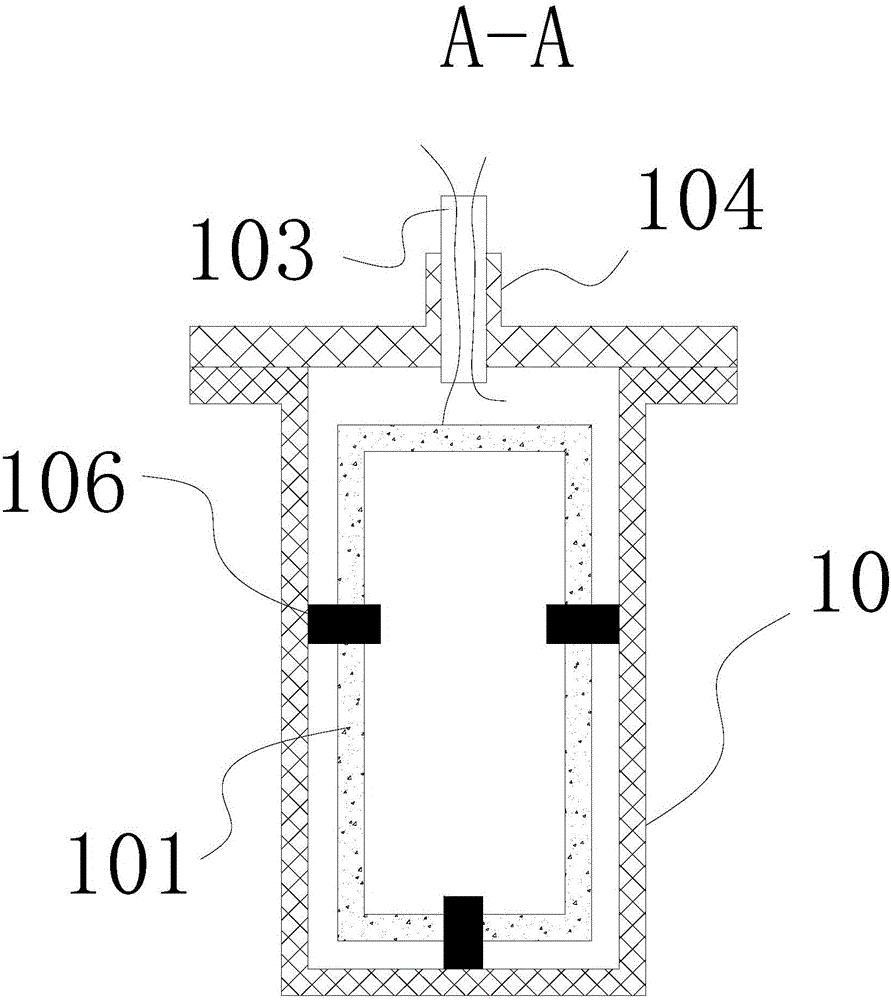

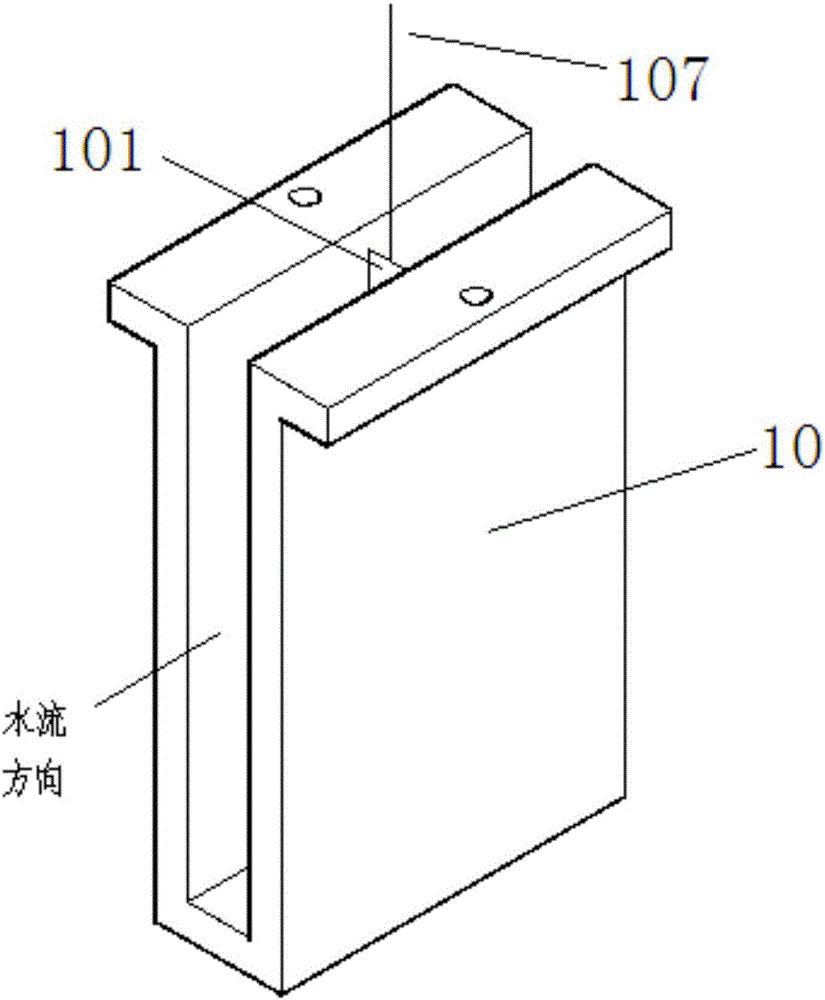

[0032] Embodiment 1; as Figure 1 to Figure 6 As shown, a microbubble drag-reducing pipeline includes a pipe body 2, the cross section of the pipe body 2 is a rectangular structure, and the two ends of the pipe body 2 are respectively provided with an inlet port and an outlet port. Connection, the inlet end and the outlet end of the rectangular pipe body 2 are respectively provided with connecting flanges 3, which facilitates the connection of the drag reducing pipeline of the present utility model with other pipelines; There is a two-dimensional channel 10, and the two ends of the two-dimensional channel 10 are respectively sealed and connected to the rectangular pipe body 2. An electrolytic ring 101 is arranged in the two-dimensional channel 10. The electrolytic ring 101 has a rectangular frame structure. The electrolytic ring 101 Fixedly arranged in the transition layer area in the two-dimensional channel 10 , the wire 107 of the electrolysis ring 101 extends out of the two...

Embodiment 2

[0037] Embodiment 2: as Figure 7 Figure 8 As shown, a micro-bubble drag reduction pipeline includes a pipe body 2, the cross section of which is a circular structure, and the two ends of the circular pipe body 2 are respectively provided with an inlet port and an outlet port. There is an electrolysis ring 101, which is in the shape of a ring, and the electrolysis ring 101 is fixedly arranged in the transition layer area in the circular tube body 2, and the wire of the electrolysis ring 101 extends out of the circular tube body 2 to connect to the power supply.

[0038] Three baffles 106 for fixing the electrolytic ring 101 are arranged on the inner wall of the circular tube body 2. The electrolytic ring 101 is fixed in the circular tube body 2 through the baffle plate 106, and the electrolytic ring can be fixed through the baffle plate 106. 101 is more stably fixed in the pipe body 2, avoiding changing its position due to the impact of water flow.

[0039] In order to facili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com