Return device of swing type clutch slave cylinder

A clutch slave cylinder and swing type technology, which is applied in the field of automobile clutch system, can solve the problems of reducing the working performance of the clutch, affecting the movement of the piston, and not being able to reset in time, and achieves low production cost, long service life and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

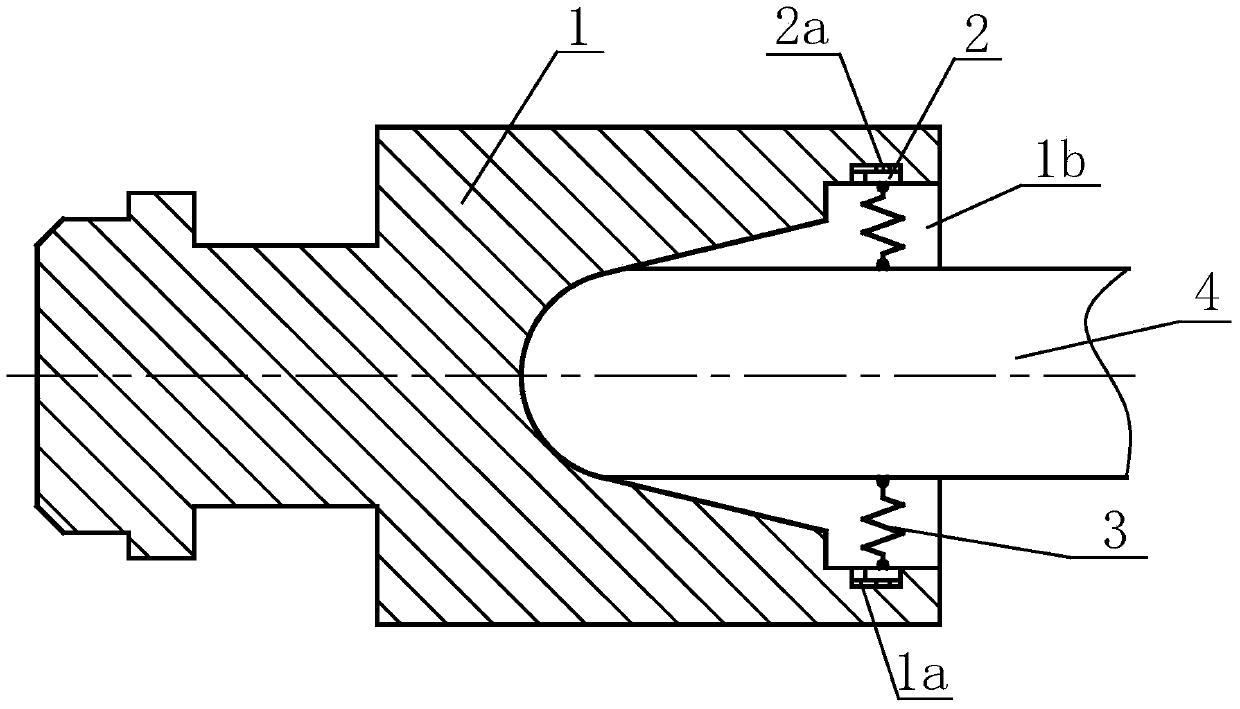

[0015] Such as figure 1 As shown, a centering device of a swinging clutch cylinder includes a piston 1, a swinging sliding block 2, a centering spring 3 and a rocking rod 4. The right side of the piston 1 is provided with a concave and cone-like shape swing groove 1b, the bottom of the swing groove 1b is hemispherical, the left end of the swing rod 4 is hemispherical, the left end of the swing rod 4 is spherically matched with the swing groove 1b, and the end of the swing groove 1b is uniform There are a plurality of reset chute 1a arranged in parallel symmetrically, and the swing sliding block 2 is correspondingly installed in the reset chute 1a, and the swing sliding block 2 cooperates with the reset chute 1a in a single degree of freedom, so One end of the return center spring 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com