Energy-saving cooling tower with auxiliary motor

An auxiliary motor and energy-saving technology, which is applied in the field of cooling equipment and energy-saving cooling towers, can solve the problems of insufficient fan blade speed and affect the cooling effect, and achieve the effects of guaranteed cooling effect, simple structure and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail with reference to the accompanying drawings and embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

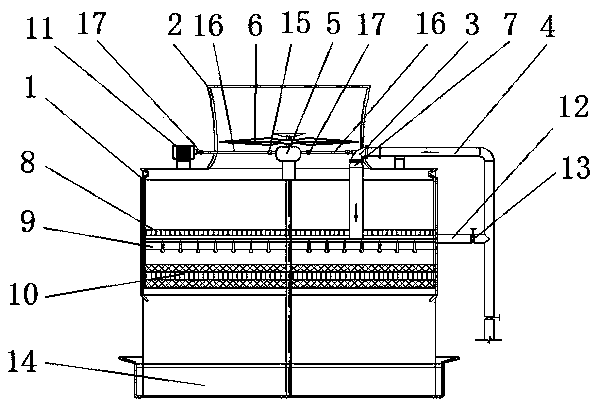

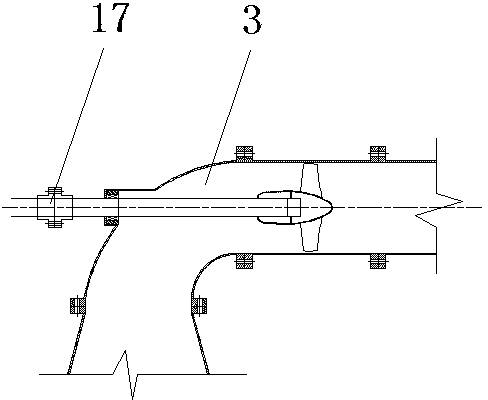

[0017] An energy-saving cooling tower with an auxiliary motor in this embodiment includes a tower body 1, a wind tube 2, a water turbine 3, a water inlet pipe 4, a gear box 5, a fan blade 6, a water return pipe 7 and an auxiliary motor 11, and the like.

[0018] In this embodiment, the air cylinder 2 is installed on the platform of the tower body 1, and the air cylinder 2 is a hollow structure. The tower body 1 is provided with a water collector 8, a water distributor 9 and a filler 10, a water collector 8, and a water distributor. The container 9 and the filler 10 are arranged in sequence from top to bottom.

[0019] In this embodiment, a pool 14 is provided at the bottom of the tower body 1. The pool 14 has the function ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com