A moving coil for an angular vibrating table

A technology of angular vibration table and moving coil, which is applied in the direction of coils, instruments, electrical components, etc., can solve the problems of poor directionality of the output torque of the moving coil, low efficiency of motor-machine conversion, and low first-order natural frequency, so as to improve the natural frequency , Increase the number of effective wire segments, the effect of small moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

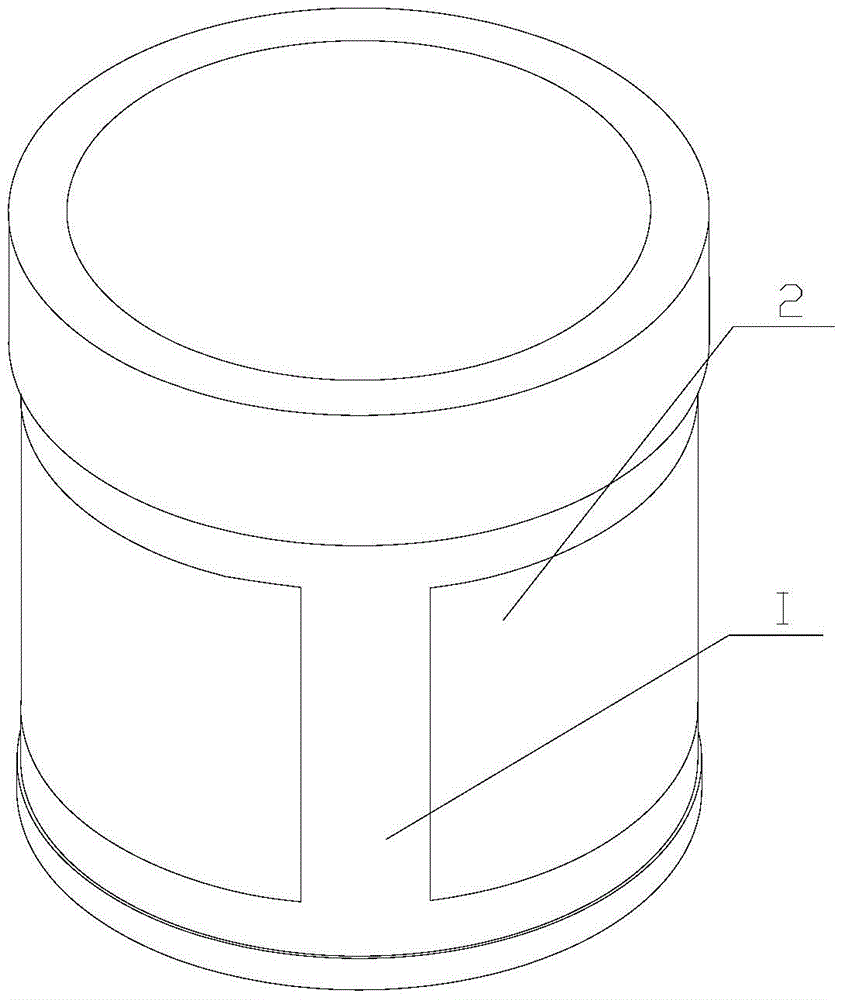

[0026] Such as figure 1 As shown, a moving coil of an angular vibrating table includes a moving coil base body 2 and a driving coil I, and the driving coil I covers the outer surface of the moving coil base body 2 .

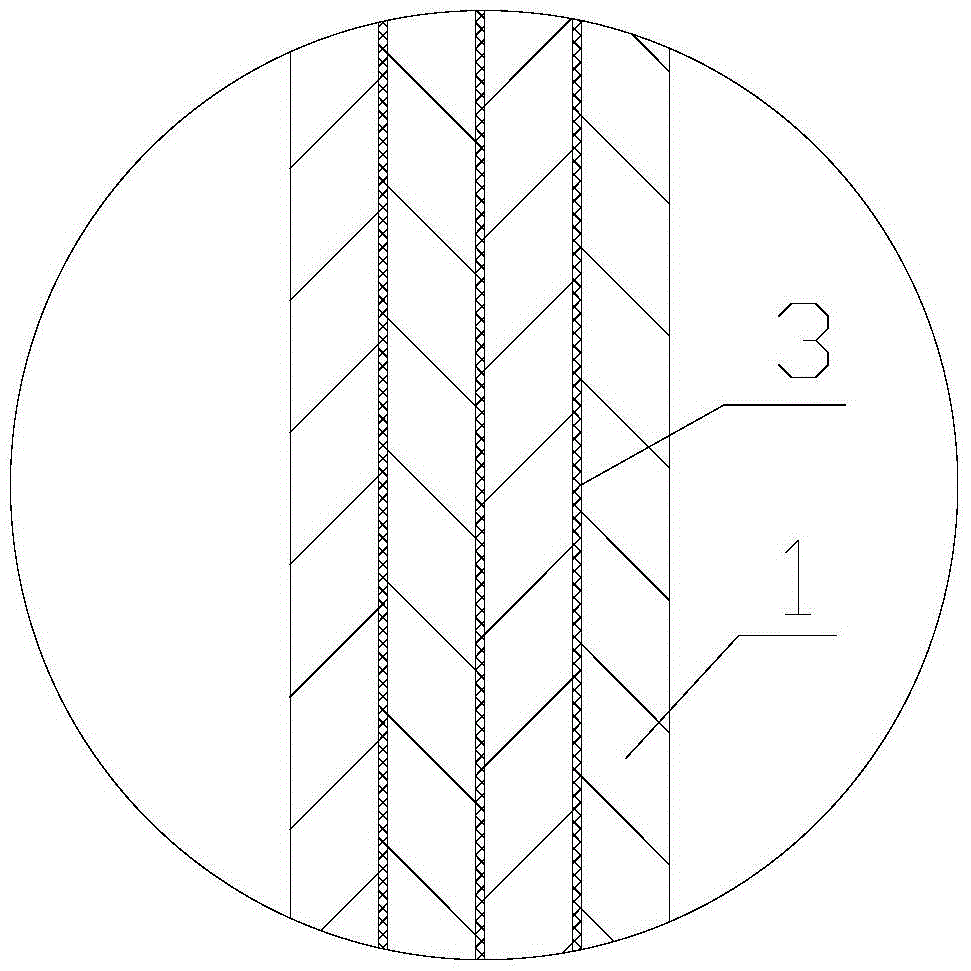

[0027] Such as figure 2 As shown, the driving coil 1 includes a coil winding 1 and an insulating layer 3, the coil winding 1 and the insulating layer 3 are arranged at intervals, the coil winding 1 has at least one layer, the insulating layer 3 is made of epoxy resin glue and glass cloth, and the insulating layer 3 Completely covers the coil winding 1 inside it.

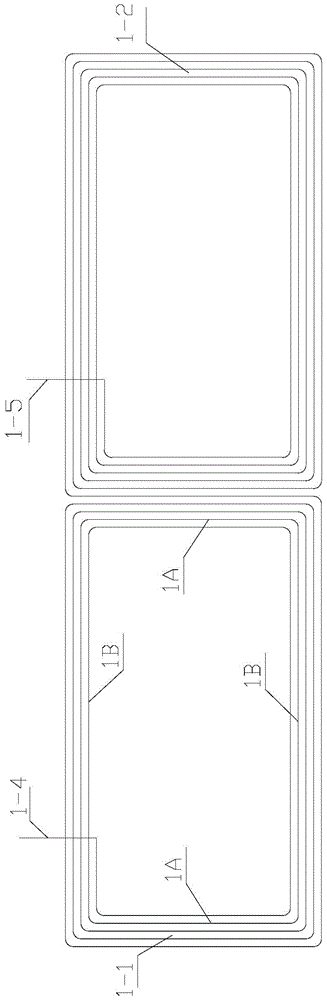

[0028] Such as image 3 As shown, each coil winding includes a first coil 1-1 and a second coil 1-2, the first coil 1-1 is wound counterclockwise from inside to outside, and the second coil 1-2 is clockwise wound from outside to inside, The first coil 1-1 and the second coil 1-2 are on the same layer, and the first coil 1-1 and the second coil 1-2 are respectively wound with multiple turns, and each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com