Ceramic substrate assembling device

A ceramic substrate and assembly device technology, which is applied in the direction of assembling printed circuits, electrical components, electrical components, etc., can solve the problems of low bonding strength, substrate susceptibility to damage, etc., to improve impact resistance, Avoid direct exposure and increase the effect of integration density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

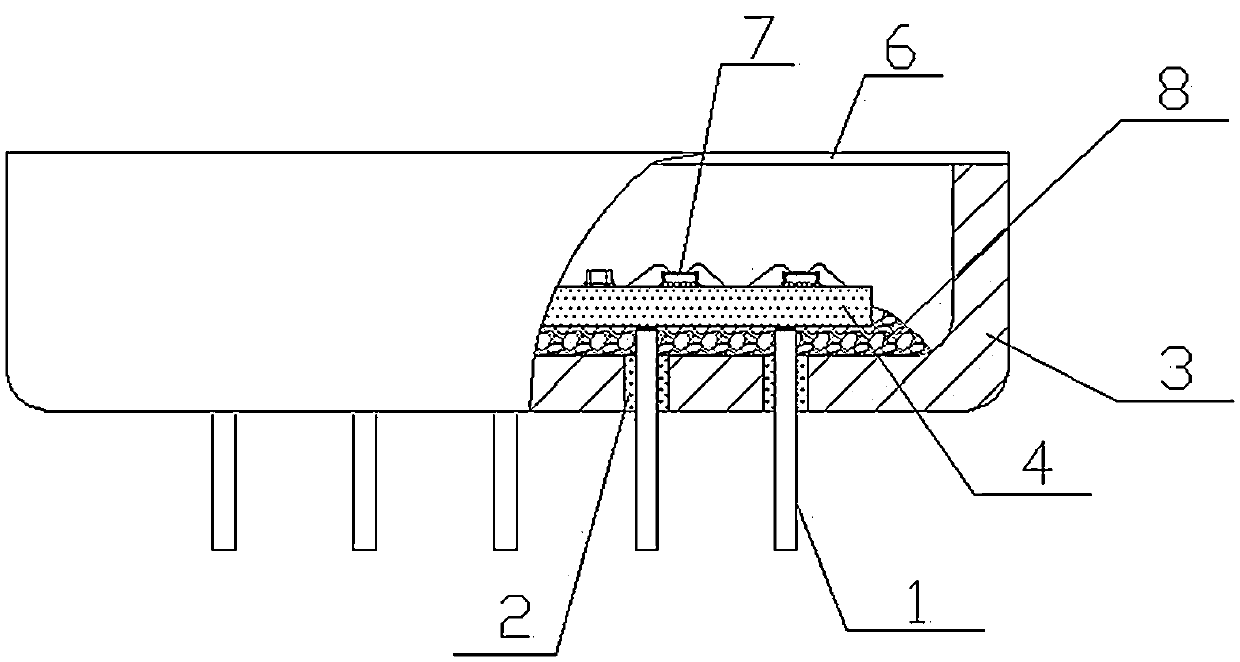

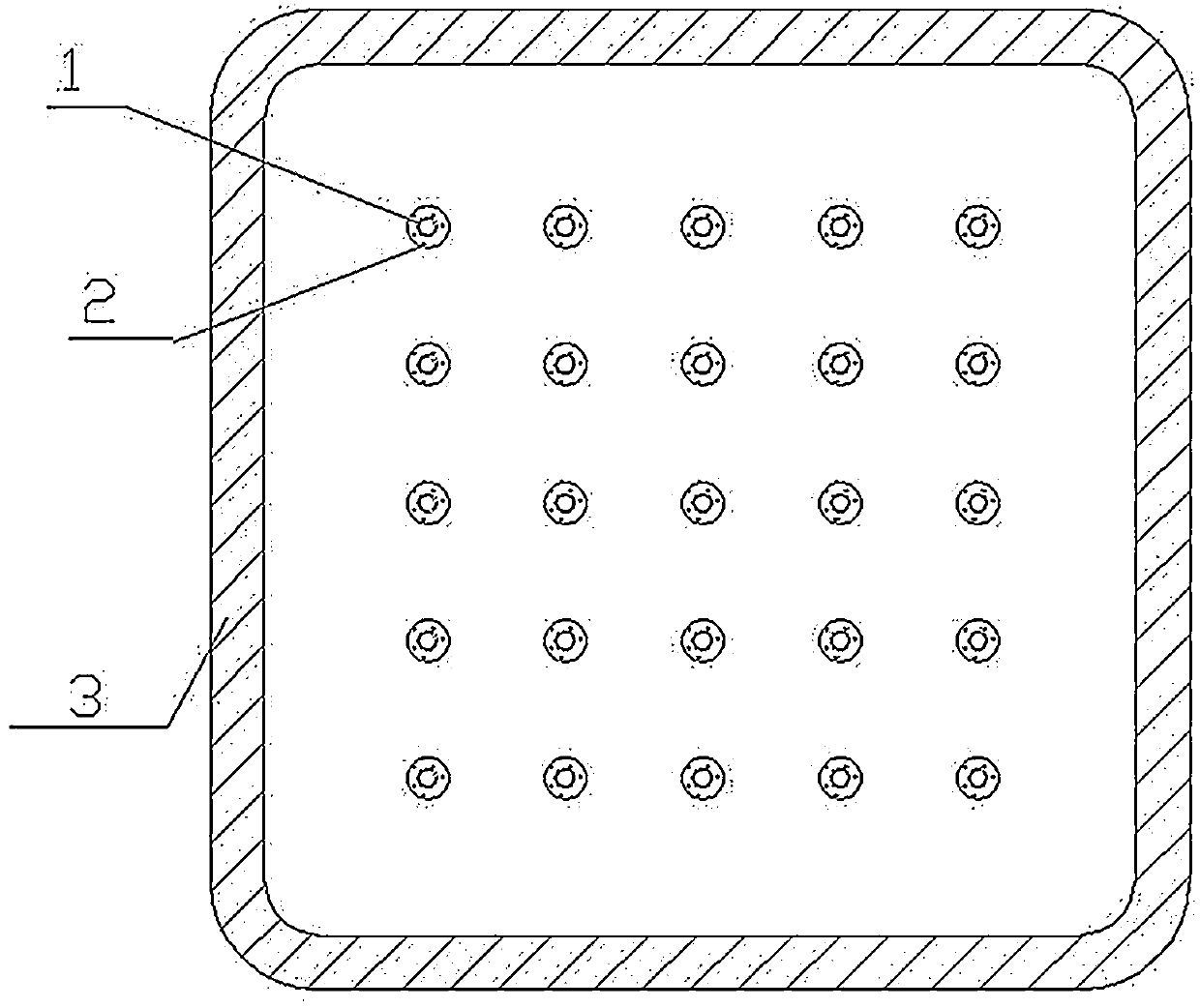

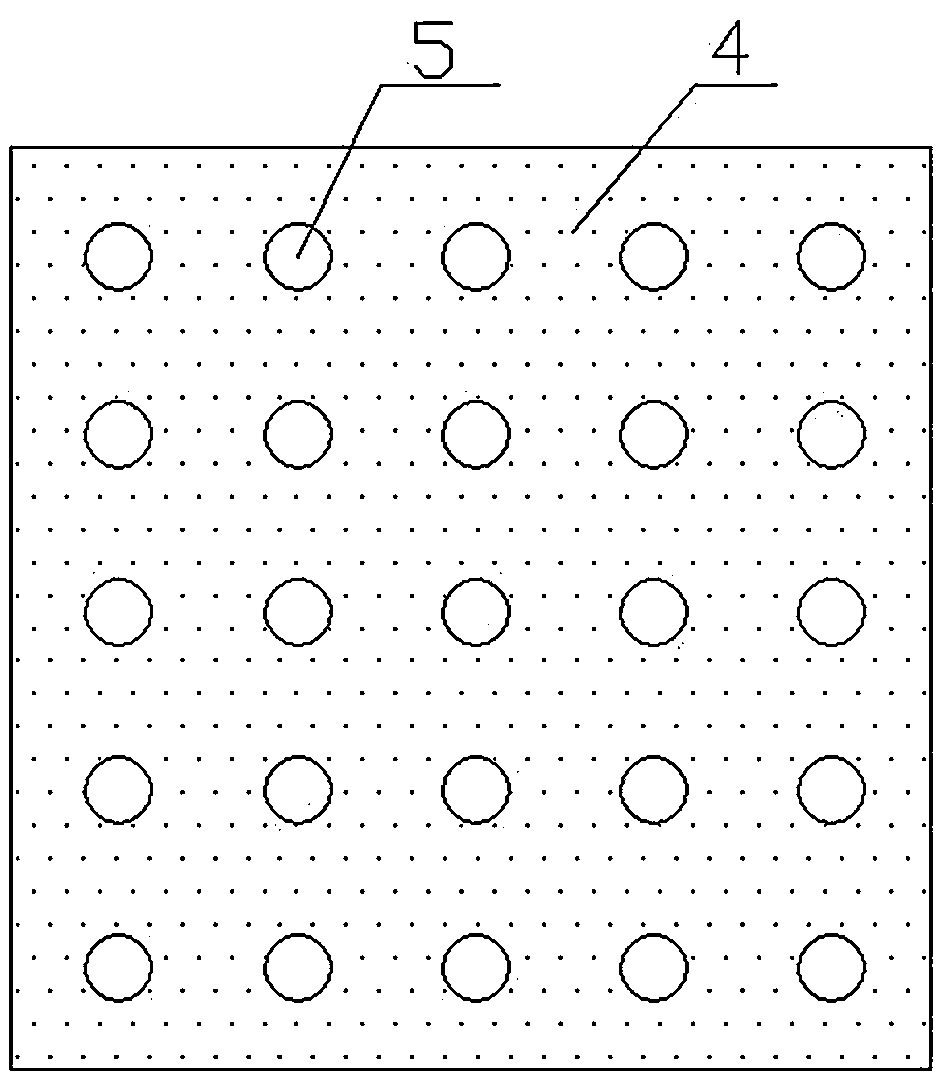

[0012] combine figure 1 and figure 2 As shown, the present invention provides a ceramic substrate assembly device, comprising a metal shell base 3 and a ceramic substrate 4 disposed in the metal shell base 3, the top surface of the ceramic substrate 4 is provided with components 7; the bottom surface of the metal shell base 3 There are arrayed outer pins 1 penetrating through the metal shell base 3, and the insulating medium 2 is used for sintering between the arrayed outer pins 1 and the metal shell base 3, and the insulating medium 2 can be a glass insulator; image 3 As shown, the bottom surface of the ceramic substrate 4 is provided with an array of pads 5 corresponding to the arrayed outer pins 1, the area of the pads is greater than the area of the ends of the outer pins, and the ceramic substrate 4 and the arrayed outer pins 1 are welded together. The disk array 5 is welded; the bottom surface of the ceramic substrate 4 and the metal shell base 3 are filled and bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com