Light-emitting diode (LED) full-automatic chip mounter

A placement machine, fully automatic technology, applied in the direction of electrical components, electrical components, electrical components to assemble printed circuits, etc., can solve the problems of low work efficiency and inability to meet large-scale production, and achieve the effect of enhancing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the accompanying drawings.

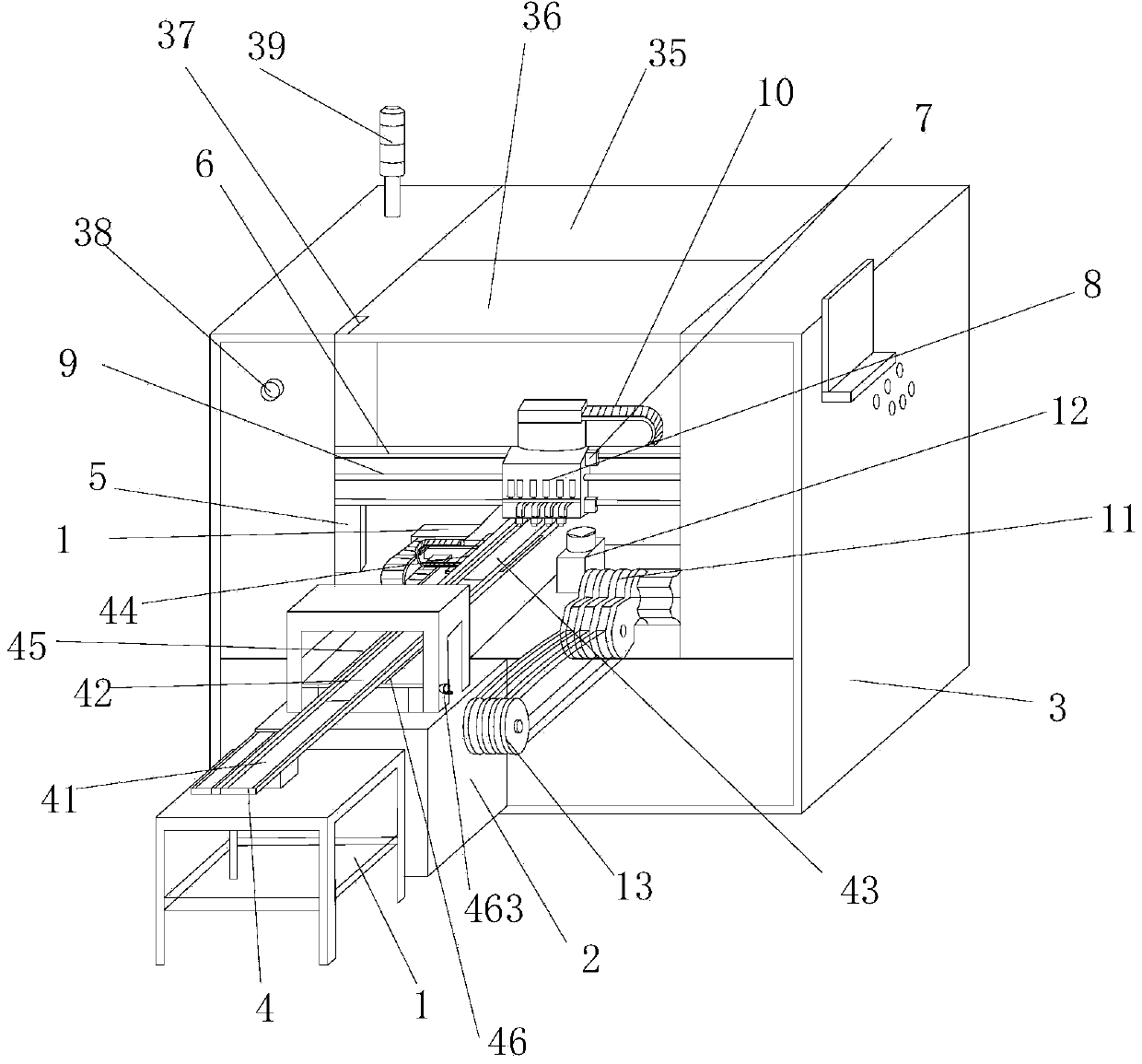

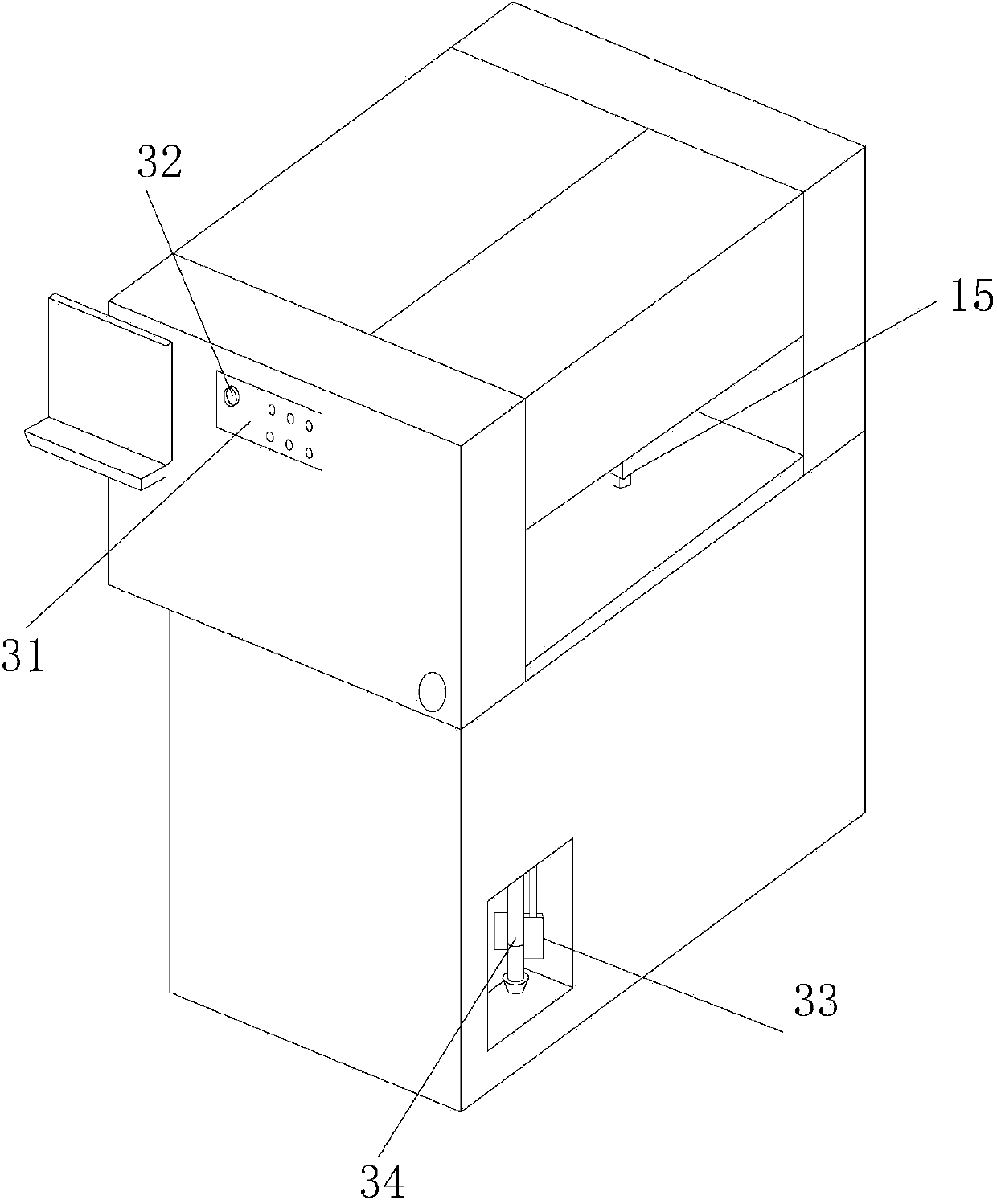

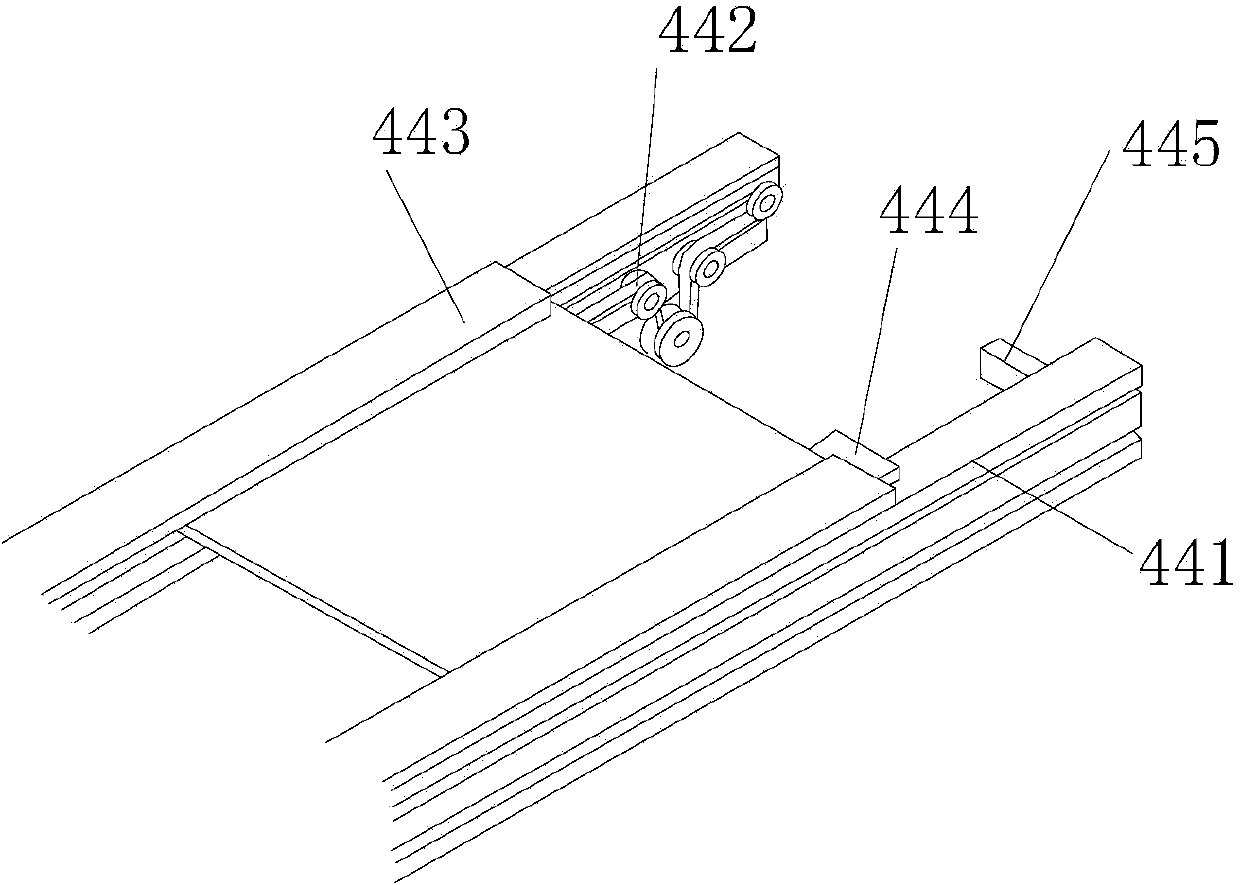

[0024] Such as figure 1 As shown, a full-automatic LED placement machine includes a feeding machine 1, a clamping machine 2 and a mounting frame 3, and the feeding machine 1, the clamping machine 2 and the mounting frame 3 pass through a conveying track 4 are connected with each other, a gantry 5 is arranged on the patch frame 3, two slide rails 6 parallel to each other are arranged on one side of the beam of the gantry 5, and a slide block 7 is arranged on the slide rail 6, and the two slide blocks 7 pass through A part is connected with the head 8, and a transmission screw 9 is arranged between the two slide rails 6. The transmission screw 9 is threadedly connected with the part head 8, and one end of the transmission screw 9 is connected with the output shaft of a transmission motor. The other side of the crossbeam of 5 is provided with the first crawler installation...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap