Long-acting controlled-release antibacterial mildew-proof material and preparation method thereof

An antibacterial, mildew-proof, slow-release technology, applied in botanical equipment and methods, nanotechnology for materials and surface science, plant growth regulators, etc. Problems such as poor antibacterial effect of mold, etc., to achieve the effect of good antibacterial and antifungal effect, good thermal stability, and obvious antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Preparation of carbon microspheres:

[0034] Dissolve glucose in deionized water, prepare a solution with a molar concentration of 0.5 mol / L, place it in a hydrothermal reactor at 180°C for a reaction time of 8 hours; after the reaction is completed, centrifuge the resulting mixture, and use Wash with deionized water and absolute ethanol respectively, and dry in a drying oven for 24 hours to obtain carbon microspheres.

[0035] Step 2: Preparation of hollow mesoporous ZnO microspheres:

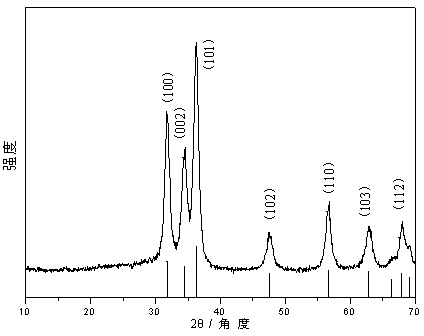

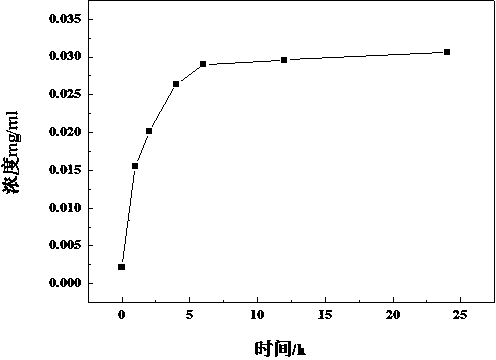

[0036] Put 0.5g of carbon microspheres in an aqueous solution of zinc acetate with a molar concentration of 0.5mol / L, ultrasonically treat for 60min, age for 8h, and after centrifugation, wash with deionized water and absolute ethanol three times respectively, dry at 500°C Calcined for 2 hours to obtain hollow mesoporous ZnO microspheres. The hollow mesoporous ZnO microspheres have a diameter of about 50nm and are assembled from a plurality of ZnO particles with a diameter of ...

Embodiment 2

[0041] Step 1: Preparation of carbon microspheres:

[0042] Dissolve glucose in deionized water, prepare a solution with a molar concentration of 0.85 mol / L, place it in a hydrothermal reactor at 170°C for a reaction time of 11 hours; after the reaction is completed, centrifuge the resulting mixture, and use Wash with deionized water and absolute ethanol respectively, and dry in a drying oven for 24 hours to obtain carbon microspheres.

[0043] Step 2: Preparation of hollow mesoporous ZnO microspheres:

[0044] Put 0.4g of carbon microspheres in an aqueous solution of zinc acetate with a molar concentration of 0.6mol / L, ultrasonically treat for 50min, age for 10h, and after centrifugation, wash with deionized water and absolute ethanol three times respectively, dry at 475°C Calcined for 2.5 hours to obtain hollow mesoporous ZnO microspheres. The hollow mesoporous ZnO microspheres have a diameter of about 50nm and are assembled from a plurality of ZnO particles with a diamete...

Embodiment 3

[0049] Step 1: Preparation of carbon microspheres:

[0050] Glucose was dissolved in deionized water to prepare a solution with a molar concentration of 1.0 mol / L, and placed in a hydrothermal reactor at 160°C for a reaction time of 14 hours; after the reaction was completed, the resulting mixture was centrifuged and used Wash with deionized water and absolute ethanol respectively, and dry in a drying oven for 24 hours to obtain carbon microspheres.

[0051] Step 2: Preparation of hollow mesoporous ZnO microspheres:

[0052] Put 0.3g of carbon microspheres in an aqueous zinc acetate solution with a molar concentration of 0.7mol / L, ultrasonically treat for 40min, age for 12h, and after centrifugation, wash with deionized water and absolute ethanol three times respectively, dry at 450°C Calcined for 3 hours to obtain hollow mesoporous ZnO microspheres. The hollow mesoporous ZnO microspheres have a diameter of about 50nm and are assembled from a plurality of ZnO particles with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap