Injection needle switch valve

A switch valve and glue injection technology, which is applied in the direction of coating and surface coating liquid device, etc., can solve the problems of lower working efficiency, glue dripping, lack of glue needle control, etc., so as to avoid glue dripping and realize precision The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

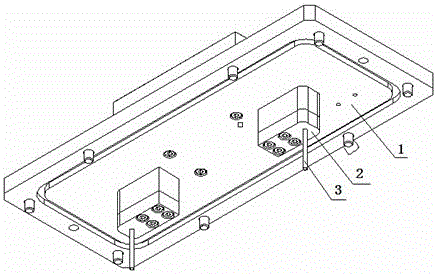

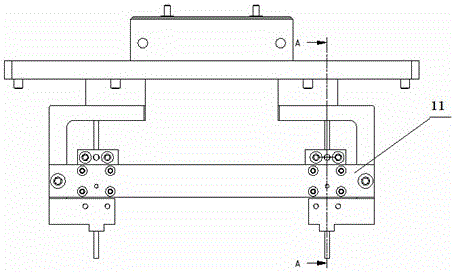

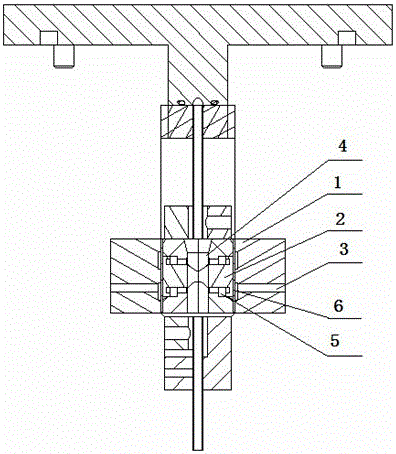

[0014] The invention discloses a glue injection needle switch valve, which is used to control the glue out of the glue injection needle. figure 2 , image 3 As shown, the injection needle on-off valve 11 is arranged on the injection needle seat, including the valve shell, the closing system inside the valve and the reset system.

[0015] The valve shell 1 is provided with a vent hole 3, and the closed system includes a flexible tube 4 for being sleeved on the injection needle tube, a movable valve core 2 placed on both sides of the flexible tube 4, and a valve core set on the valve. Diaphragm 6 on the outside of core 2. The flexible tube 4 is a silicone tube, and the valve core diaphragm 6 is perpendicular to the vent hole 3. When the vent hole 3 is ventilated, the valve core diaphragm 6 is pushed, thereby driving the valve core 2 to the flexible tube 4. Squeeze the flexible tube at all times.

[0016] The reset system is composed of an elastic element 5 arranged inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com