A preparation method of laser rapid prototyping niobium-tungsten alloy nozzle

A technology of laser rapid prototyping and alloy spraying, which is applied in the field of nozzle preparation, can solve the problems of low processing efficiency, increased material brittleness, unavoidable powder oxidation, etc., and achieve the effects of short processing cycle, improved hardness and brittleness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

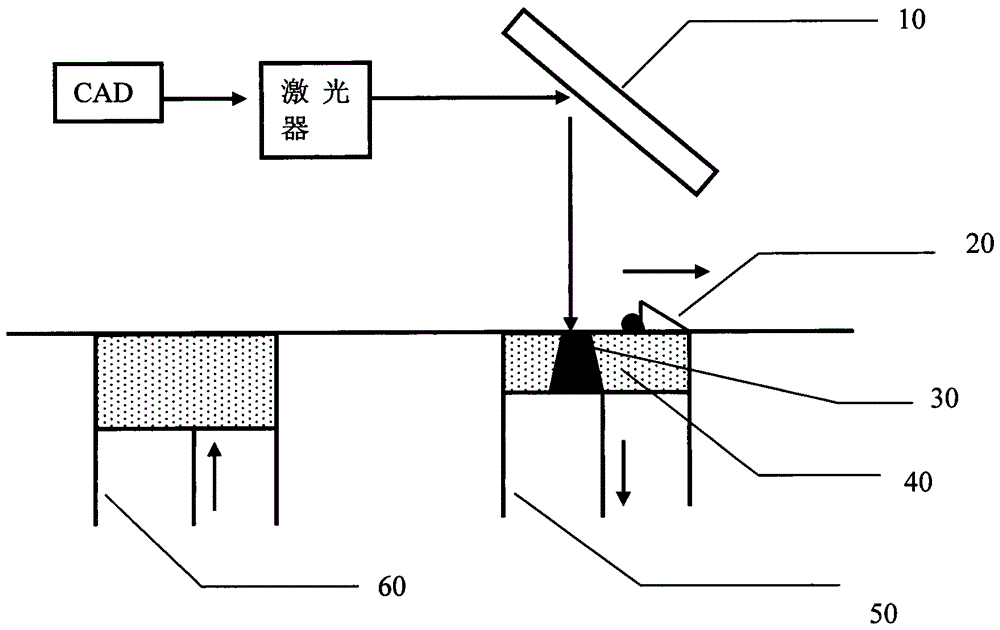

[0024] A preparation method of laser rapid forming niobium-tungsten alloy nozzle, characterized in that it comprises the following steps:

[0025] (1) Use CAD drawing software to design the three-dimensional solid model of the nozzle, and use the discrete program to slice the model to obtain a multi-layer two-dimensional section of the solid model, and save it as an STL file, and transfer the data of the STL file to the selective laser Sintering rapid prototyping system;

[0026] (2) Evenly mix tungsten powder and niobium powder in a ratio of 5% and put them into the powder cylinder of the 3D printer;

[0027] (3) Pass protective gas into the molding cylinder of 3D printer;

[0028] (4) Evenly spread a layer of niobium-tungsten powder with a thickness of 0.08mm on the working table with a powder spreading roller, and preheat the working table to 2000°C;

[0029] (5) The scanning speed of the design laser is 20mm / s, the sintering temperature is 2500°C, and the laser is contro...

Embodiment 2

[0035] A preparation method of laser rapid forming niobium-tungsten alloy nozzle, characterized in that it comprises the following steps:

[0036] (1) Use CAD drawing software to design the three-dimensional solid model of the nozzle, and use the discrete program to slice the model to obtain a multi-layer two-dimensional section of the solid model, and save it as an STL file, and transfer the data of the STL file to the selective laser Sintering rapid prototyping system;

[0037] (2) Evenly mix tungsten powder and niobium powder in a ratio of 15% and put them into the powder cylinder of the 3D printer;

[0038] (3) Pass protective gas into the molding cylinder of 3D printer;

[0039] (4) Evenly spread a layer of niobium-tungsten powder with a thickness of 0.3mm on the working table with a powder spreading roller, and preheat the working table to 2200°C;

[0040] (5) The scanning speed of the design laser is 200mm / s, the sintering temperature is 2700°C, and the laser is contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com