A Welding Process for Large Diameter Ring Parts

A welding process and technology for ring parts, applied in the field of large-diameter ring part welding technology, can solve the problems of increasing part processing costs, reducing part production efficiency, increasing labor intensity, etc., to reduce welding processing costs, improve production efficiency, and reduce labor. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below in conjunction with the accompanying drawings of the embodiments, but the scope of protection is not limited to the description.

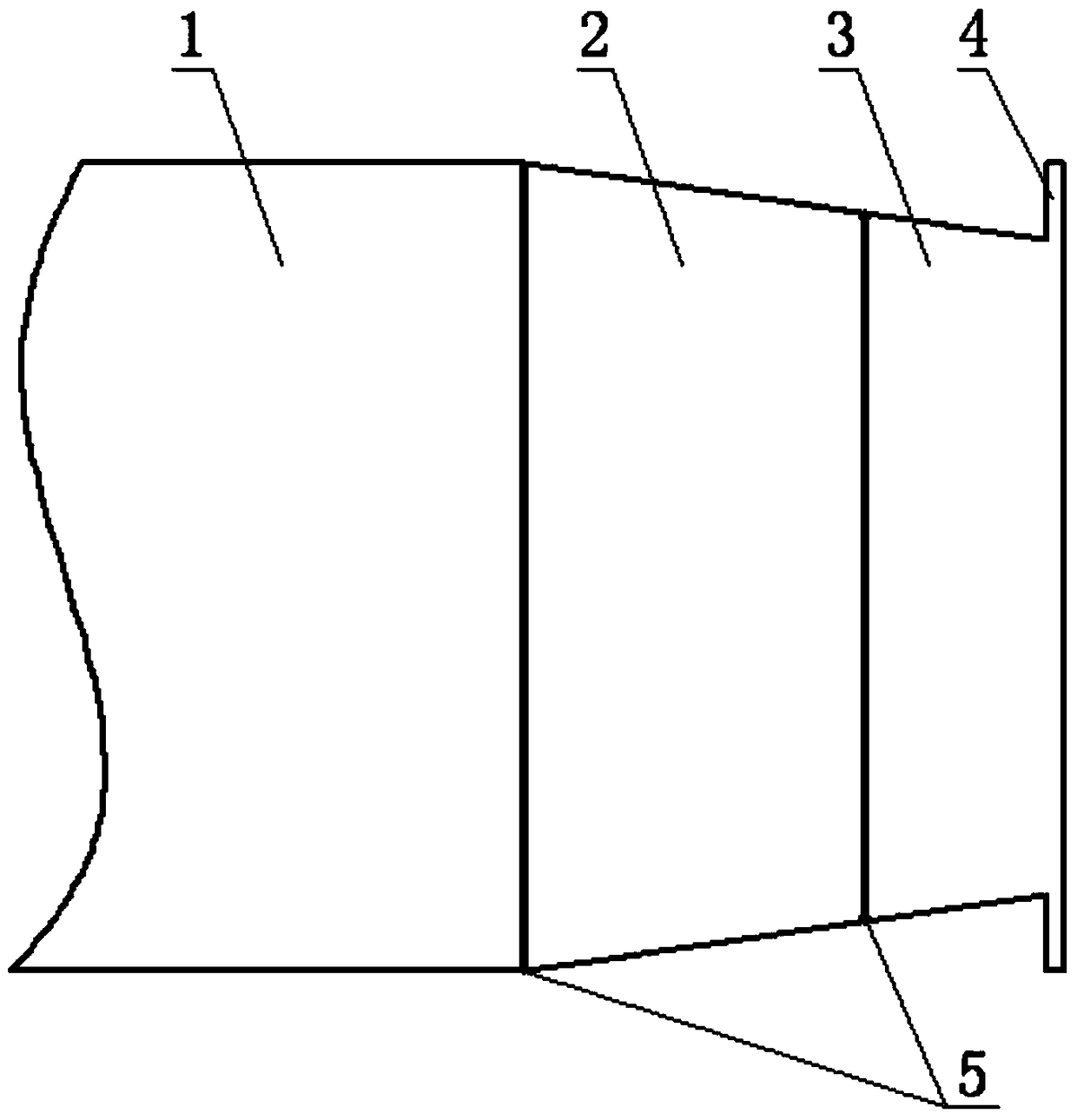

[0024] Such as figure 1 As shown, part A1, part B2 and part C3 are large-diameter annular components, wherein part C3 has a flange edge 4, and the welding process of the present invention is used to weld part A1, part B2 and part C3 together, Its specific process steps are as follows:

[0025] (1) Cleaning before welding: Before welding, clean the welding grooves of parts A1, B2 and C3 to remove scale, rust or oil around the circular weld to ensure that there are no impurities around the groove of the weldment;

[0026] (2) Preliminary spot welding positioning and connecting parts: Use manual positioning spot welding with filler argon arc welding to perform preliminary positioning and connection of the parts to be welded; The strength of the butt joint is high; when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com