Four-speed output air pressure trailer brake valve

A technology of brake valve and air pressure, which is applied in the direction of control valve and air release valve, vehicle parts, transportation and packaging, etc. It can solve the problems of slow recovery, wear of brake shoes, and slow speed of releasing the brake, so as to avoid rear wheel lock Dead and sideslip, improve the effect of braking sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

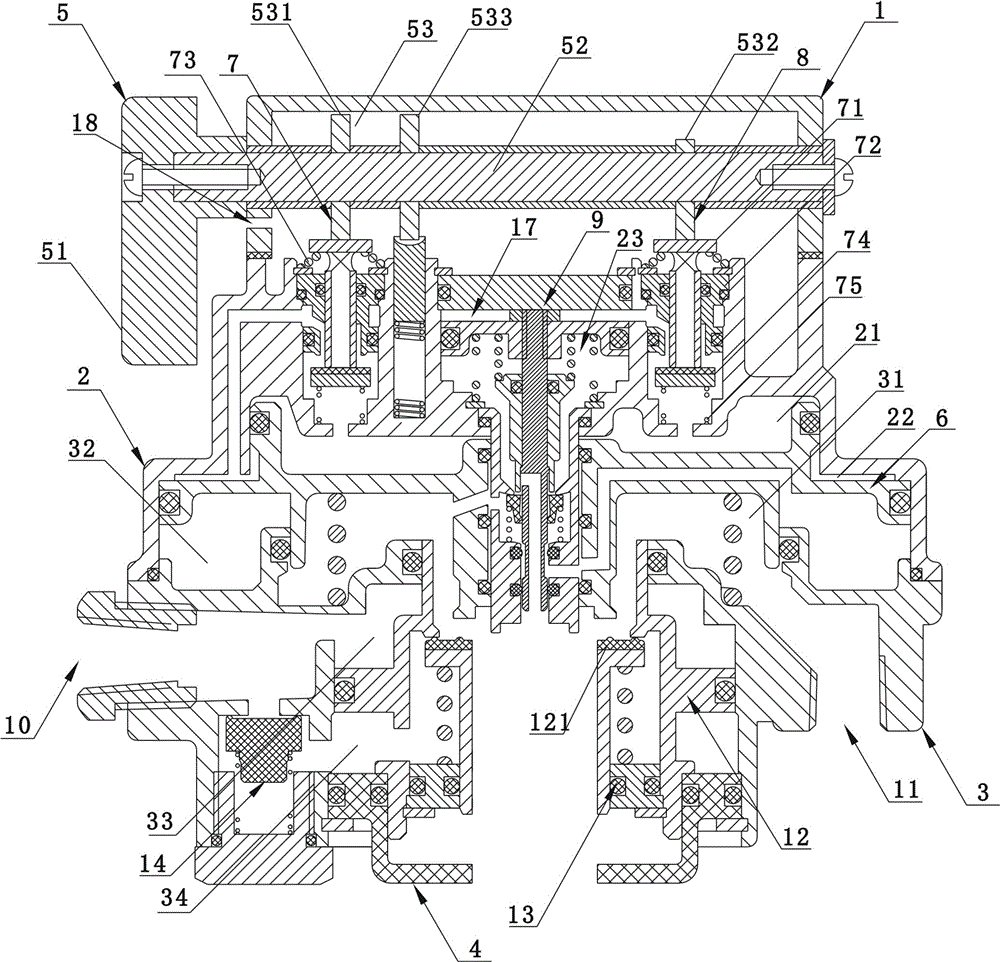

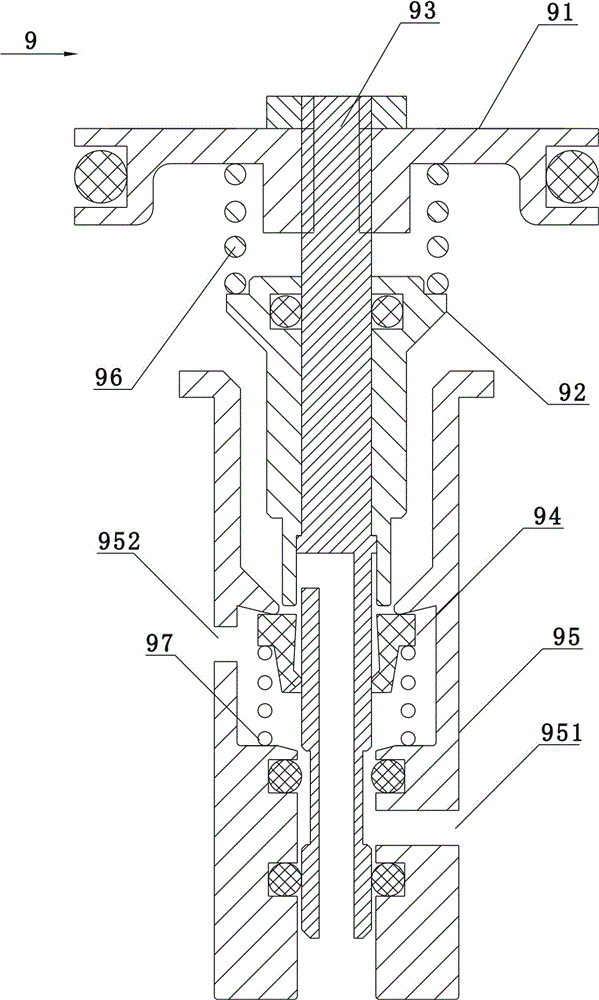

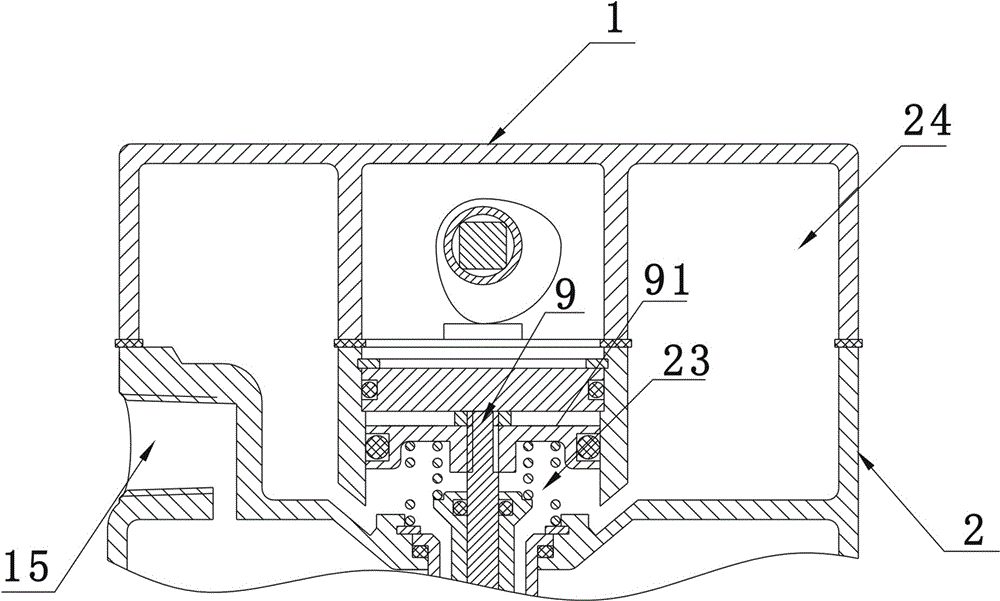

[0022] figure 1 Shown is a sectional view of a four-speed output air pressure trailer brake valve provided by an embodiment of the present invention. figure 2 shown as figure 1 An enlarged cross-sectional view of the control piston assembly in the four output air pressure trailer brake valve shown. image 3 shown as figure 1 The sectional view of the upper cover in the four-speed output air pressure trailer brake valve shown after being rotated 90 degrees. Figure 4 shown as figure 1 Outline drawing of the four output air pressure trailer brake valve shown.

[0023] The invention provides a four-speed output air pressure trailer brake valve package with an upper cover 1, an upper body 2, a lower body 3, a lower cover 4, a gear selection assembly 5, a relay piston 6, a control chamber switching valve 7, and an air outlet chamber switching valve 8 , control piston assembly 9 , air inlet port 10 , air outlet port 11 , manipulation port 15 and air supply port 16 . The gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com