Brake for automobile in danger

A technology for automobiles and time, which is applied to vehicle parts, brakes, brake components, etc., and can solve problems that cannot be considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

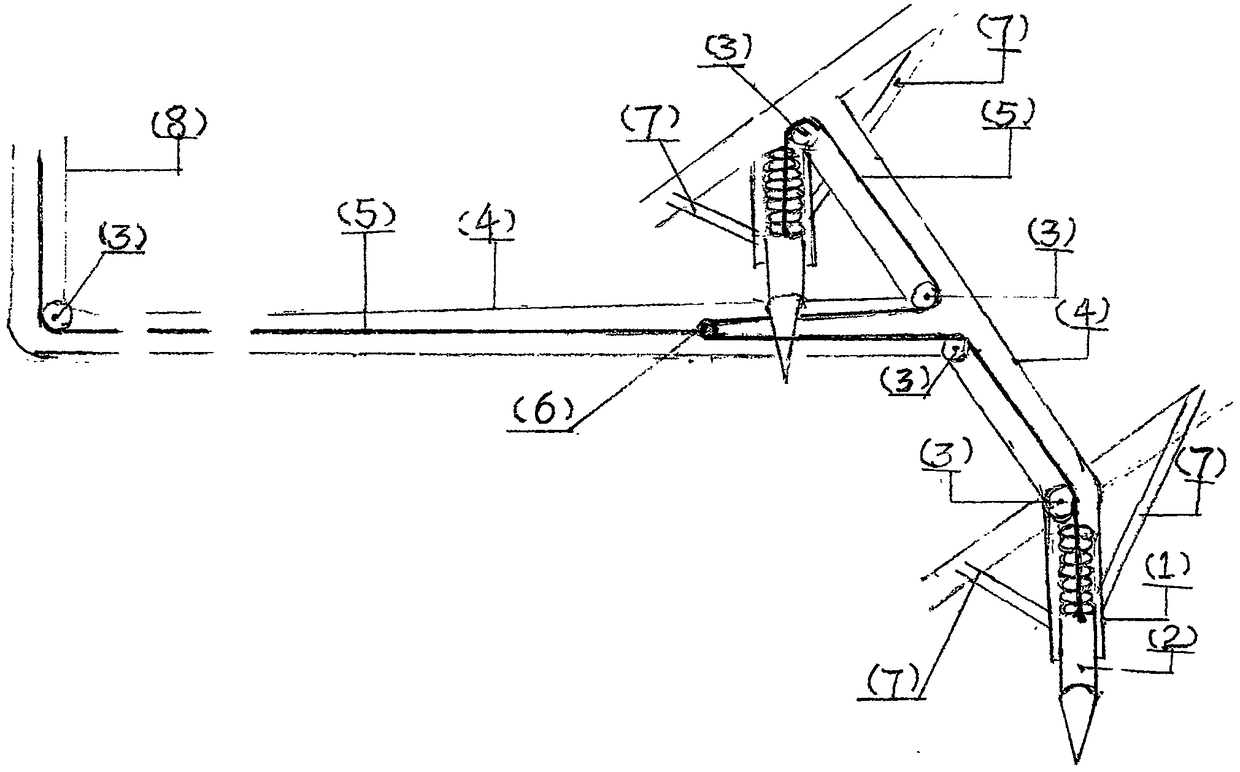

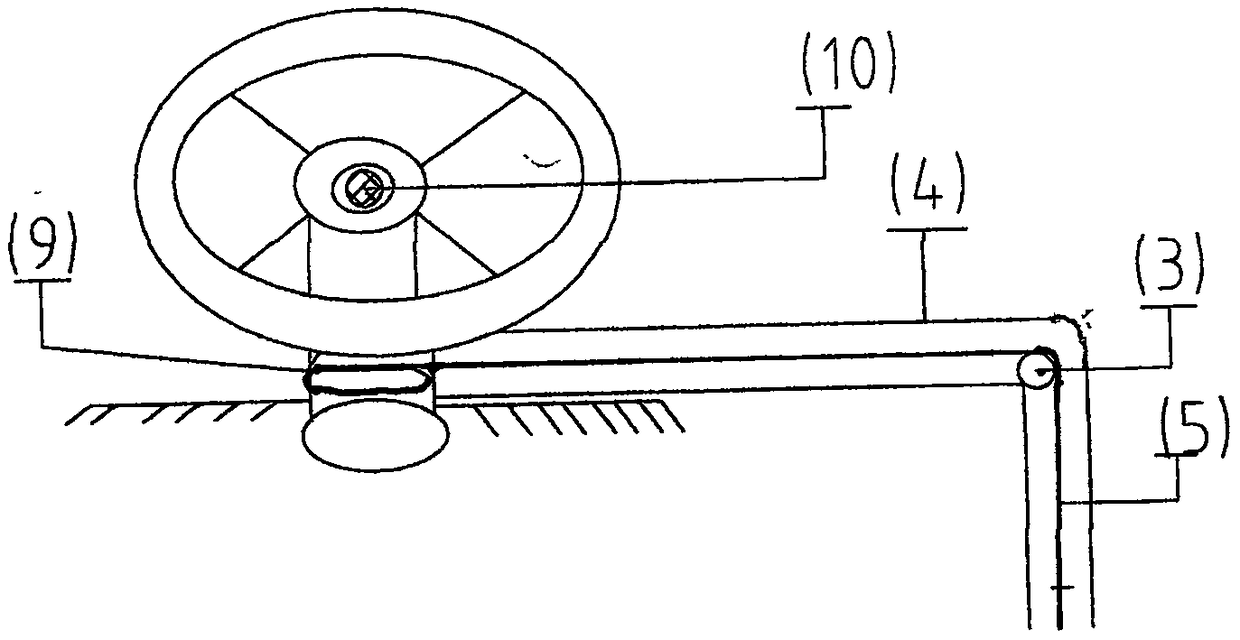

[0029] The technical solutions of the present invention are described below in conjunction with the accompanying drawings, and the listed numbers have not been accurately calculated, and do not affect the technical scope of the present invention.

[0030] 1. Install (weld) a "T"-shaped angle steel frame on the chassis of the car, so that the collision force generated during braking can be evenly transmitted to the beam and floor of the car, without damaging the parts of the car. The bottom of the "T" is about the distance from the two rear wheels of the car, and the handle of the "T" is about 20cm from the driver's seat to the back of the two rear wheels of the car, that is, the rear of the car. The best place, but here is conducive to the design and installation and the hiding of short steel pipes. The angle steel groove of the "T" handle is opposite, and it is mainly used to install welded small steel pipes in the angle groove figure 1 (4) Helian welded short steel pipe fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com