Conveying device for substrates of touch screens

A technology for conveying devices and screen substrates, applied in the field of machinery, can solve problems such as scratches, abrasions, stains and powder layers on the substrates, touch marks on the surface of the substrates, and easy to produce surfaces, etc., to achieve protection Good effect, good guiding effect, high cleanliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

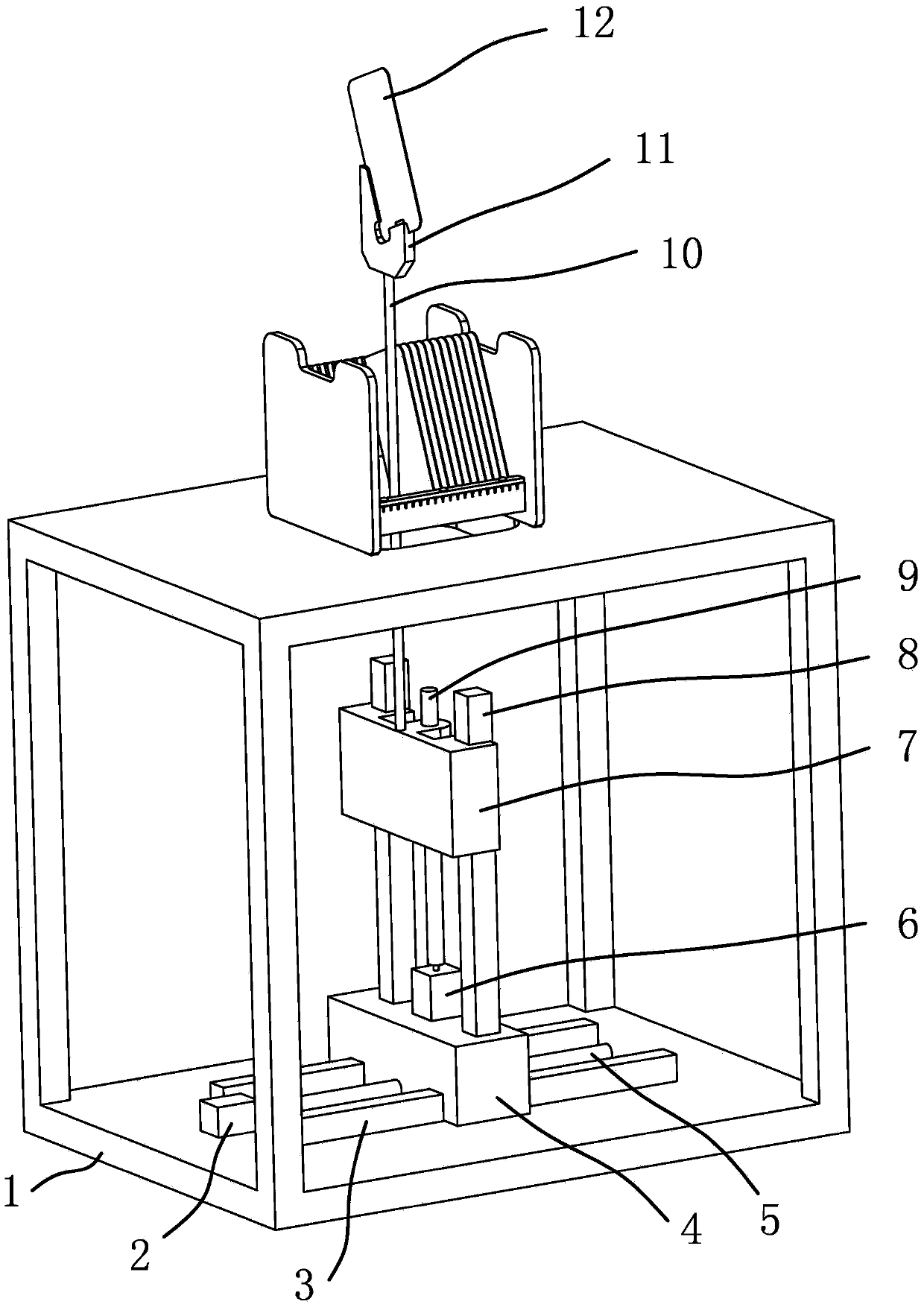

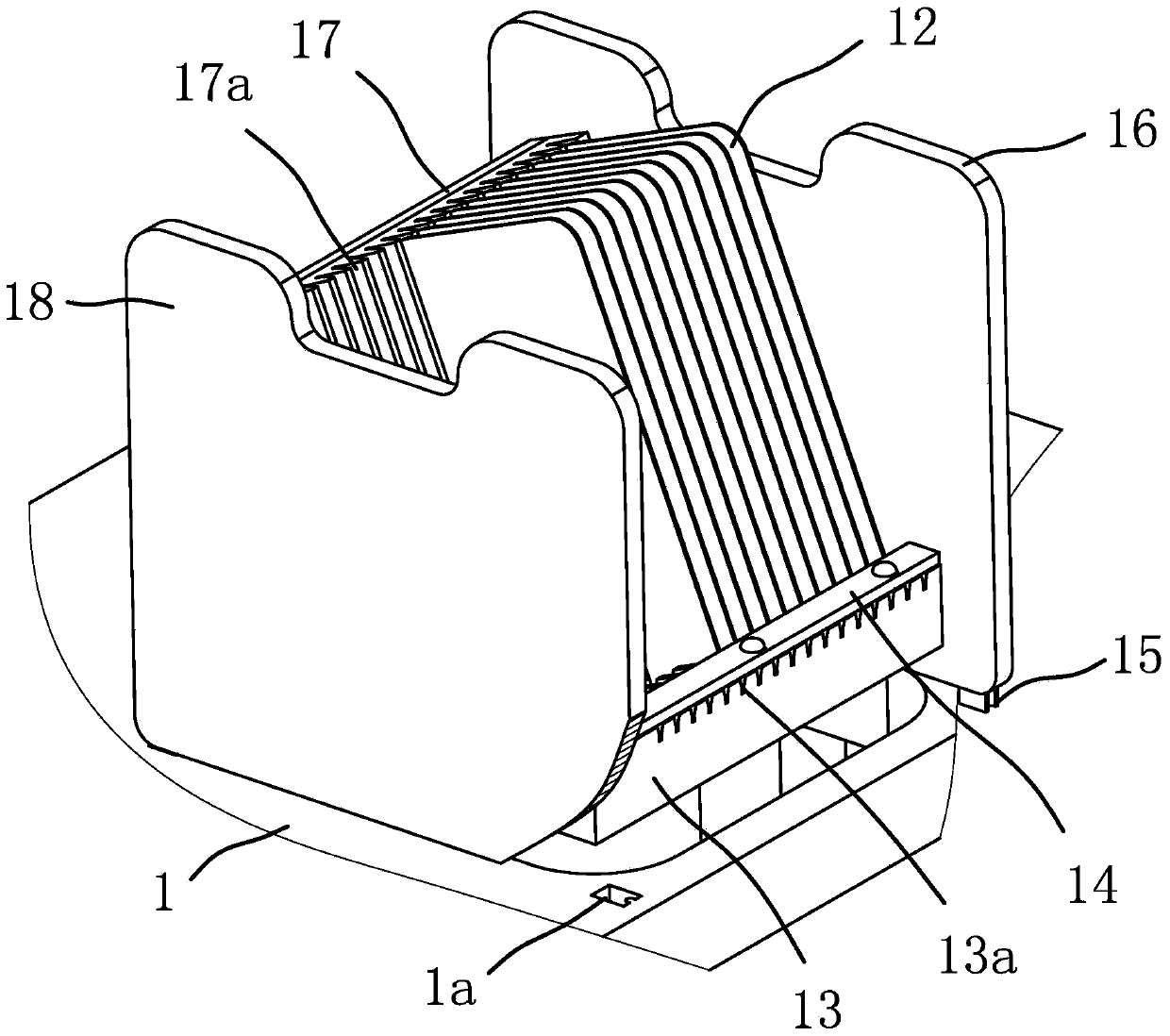

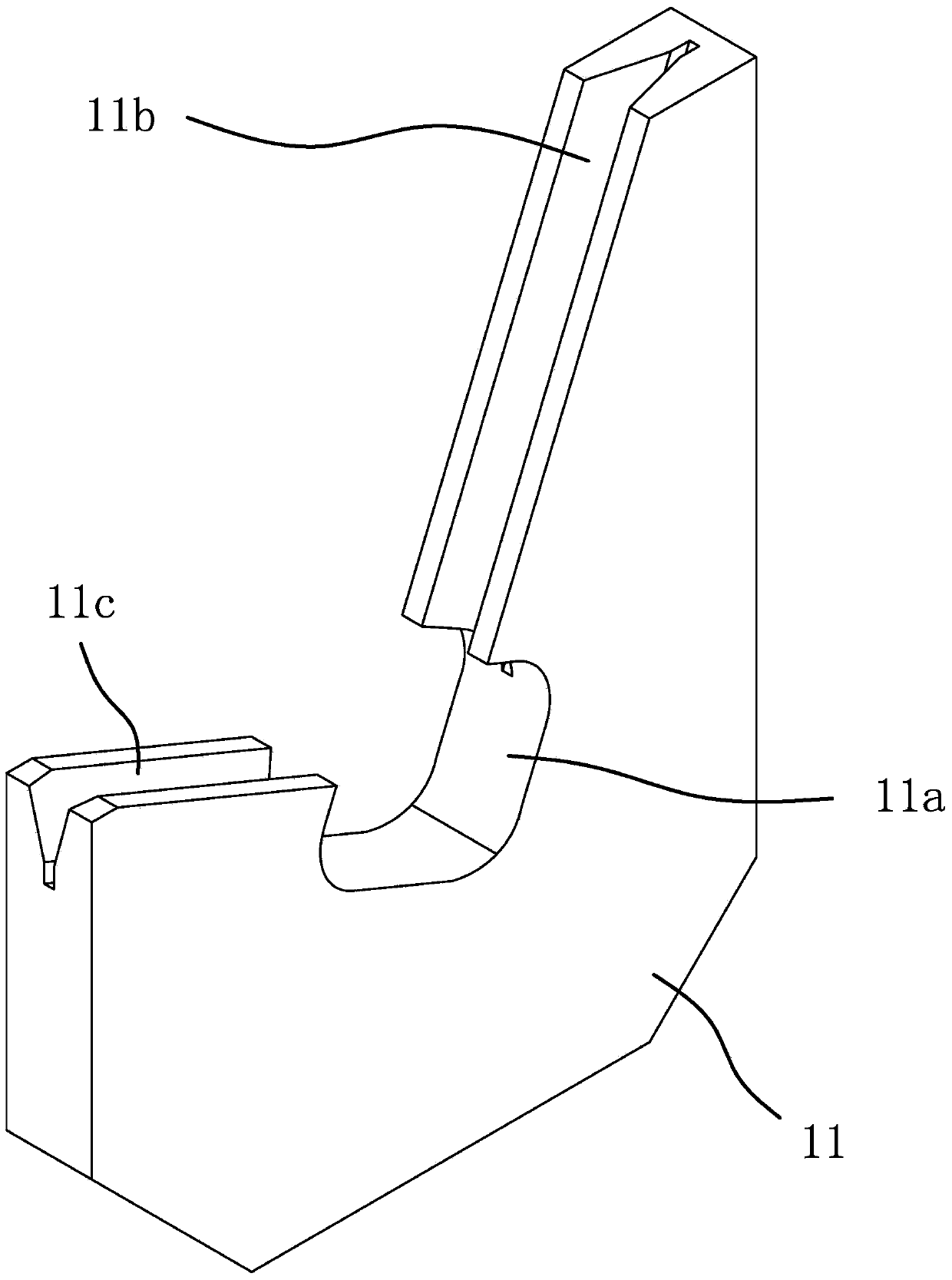

[0044] like figure 1 , figure 2Shown, the delivery device of this touch screen substrate comprises a frame 1, and this device comprises the storage box that is box-shaped and is connected on the frame 1 and the bracket 11 that is positioned at the bottom of the storage box, and the bottom of the storage box has Positioning block 15, a positioning hole 1a is provided on the frame 1, and the positioning block 15 at the bottom of the storage box is fixed in the positioning hole 1a on the frame 1, so that the storage box is connected on the frame 1; the storage box One side of the storage box has a plurality of positioning grooves 17a recessed in a strip shape, and the other side of the storage box has several positioning grooves 13a with the same number as the positioning grooves 17a and one-to-one corresponding positions. Positioning parts for positioning the adjacent two edges of the touch screen substrate 12 are formed between the positioning groove one 17a and the positioni...

Embodiment 2

[0056] The content in the second embodiment is roughly the same as that in the first embodiment, except that the driver one in the first embodiment is above the second driver; and in the second embodiment, as Figure 4 As shown, the first driving member in the second embodiment is below the second driving member.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com