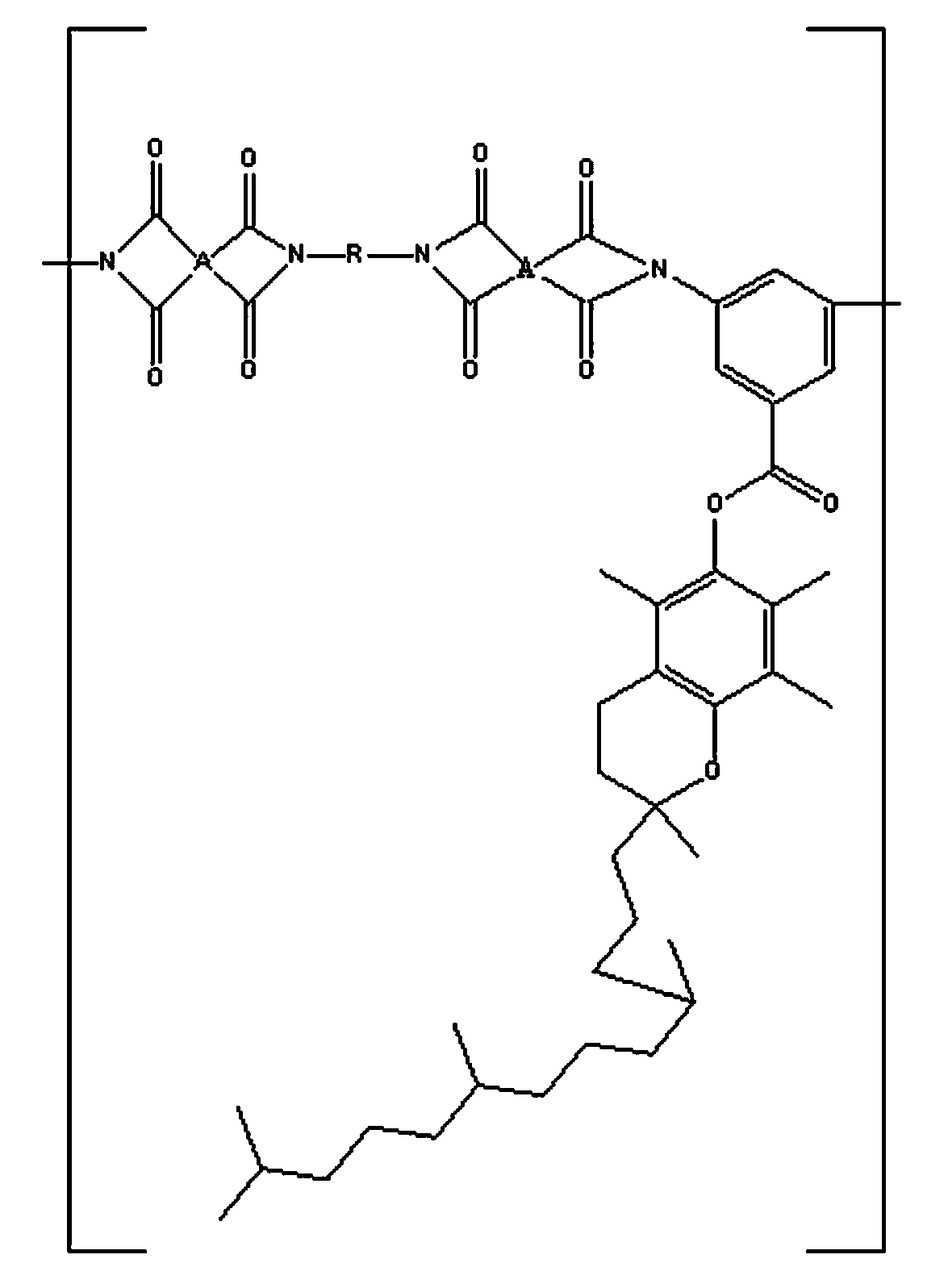

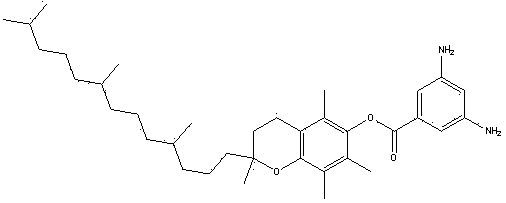

Method for preparing polyimide liquid crystal aligning agent

A technology of liquid crystal aligning agent and polyimide, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of high single-point defect rate and insufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0052] At room temperature, under nitrogen protection, 10 g of the specific diamine was dissolved in 50 ml of N-methylpyrrolidone. Add 14.5 g of pyromellitic dianhydride and stir for 2 hours. Add 10 g of 4,4'-diaminobenzenemethane and stir for 36 h. It was diluted with 600 ml of 1,4-butyrolactone to obtain a polyimide liquid crystal alignment liquid. A liquid crystal cell is made, and the measured pretilt angle is 10.5 degrees.

preparation Embodiment 2

[0054] At room temperature, under nitrogen protection, 10 g of the specific diamine was dissolved in 200 ml of N-methylpyrrolidone. Add 11.7 g of pyromellitic dianhydride and stir for 2 hours. Add 8 g of 3,3'-diaminobenzophenone, and stir for 36 h. It was diluted with 200 ml of 1,4-butyrolactone to obtain a polyimide liquid crystal alignment liquid. A liquid crystal cell is made, and the measured pretilt angle is 11.1 degrees.

[0055]

preparation Embodiment 3

[0057]At room temperature, under nitrogen protection, 10 g of the specific diamine was dissolved in 100 ml of N-methylpyrrolidone. Add 10.5 g of 3,4,9,10-perylenetetracarboxylic anhydride, and stir for 2 hours. Add 8 g of 3,3'-diaminobenzophenone, and stir for 36 h. It was diluted with 500 ml of 1,4-butyrolactone to obtain a polyimide liquid crystal alignment liquid. A liquid crystal cell is made, and the measured pretilt angle is 12.4 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com