Warm-mixing regenerated asphalt and preparation method thereof

A technology of recycled asphalt and warm mix regenerant, which is applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of high mixing temperature, impact on road performance, low regeneration ratio, etc. The effect of increased utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

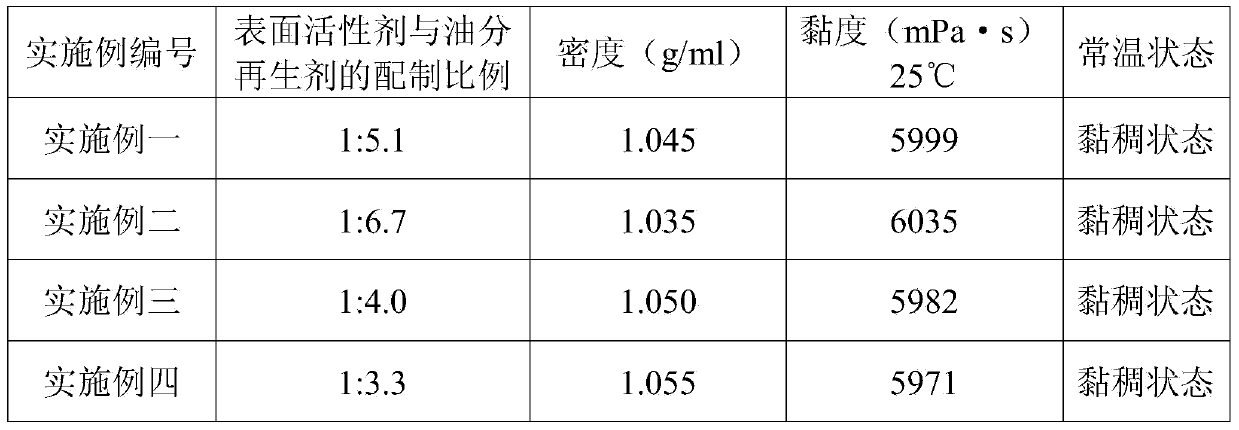

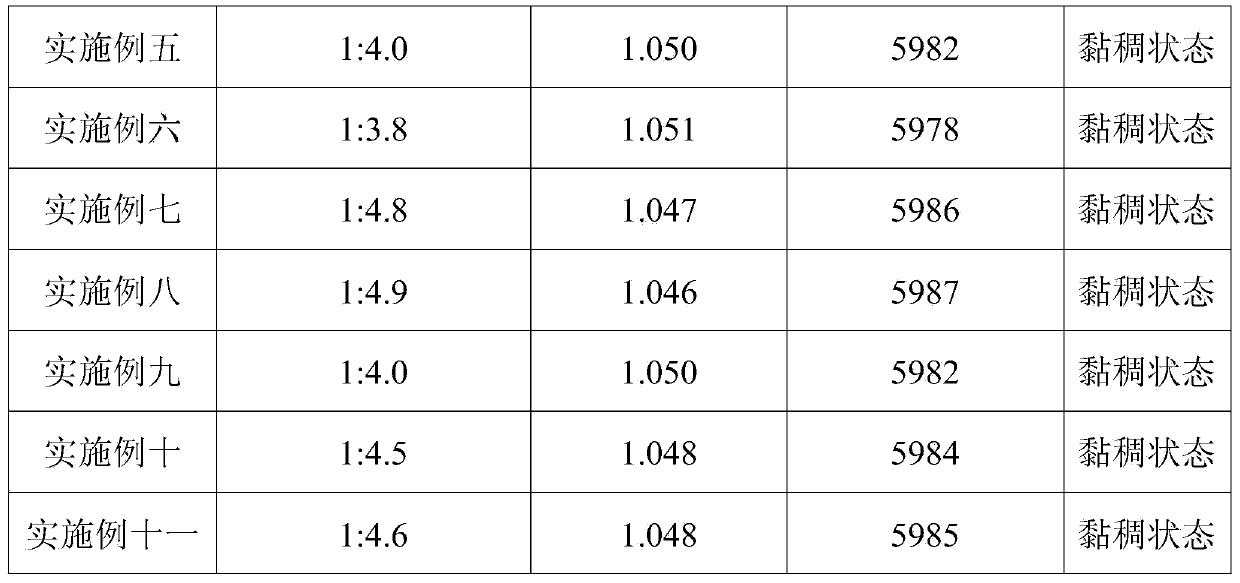

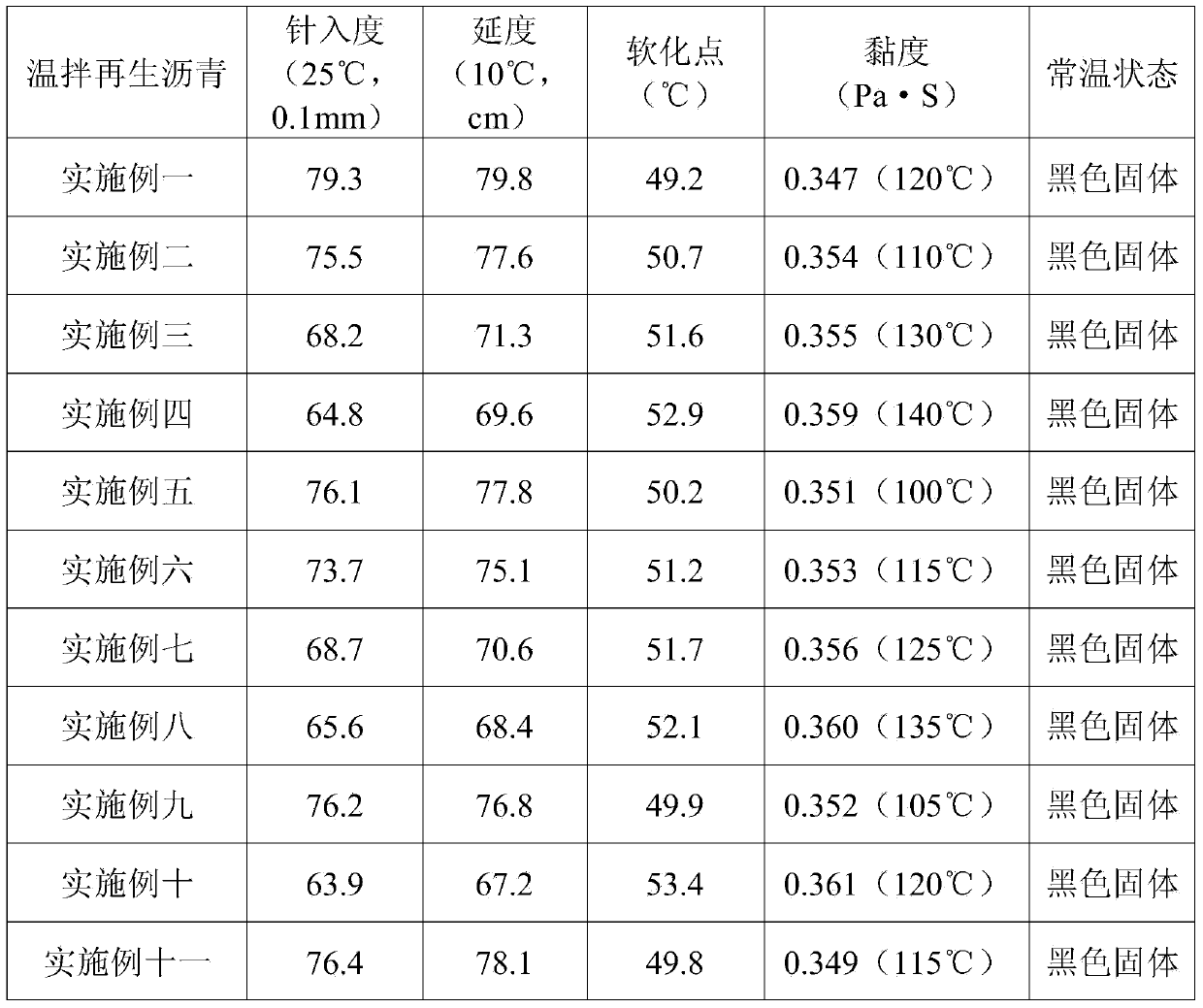

Examples

Embodiment 1

[0069] A warm-mix regenerated asphalt is prepared by mixing asphalt and a composite warm-mix regenerant. The asphalt is new asphalt. The quality of asphalt binder is 10000g, wherein the content of new asphalt is 70%, namely 7000g, and the content of aged asphalt is 30%, namely 3000g. Composite warm-mix regeneration agent includes surfactant and oil regeneration agent. The surfactant is fatty acid glyceride, which is a yellow, transparent, liquid substance at room temperature; the oil regeneration agent is the extracted oil from refined lubricating oil, which is a dark yellow, viscous liquid substance at room temperature.

[0070] The preparation of the above-mentioned composite warm mixing regenerant comprises the following steps:

[0071] (1) Take fatty acid glyceride and the extracted oil when refining lubricating oil according to a certain ratio.

[0072] The amount of fatty acid glyceride added is 0.5% of the mass of asphalt binder, that is, P 脂肪酸甘油酯 =(P 1 +P 2 ) × A...

Embodiment 2

[0080] A warm-mix regenerated asphalt is prepared by mixing asphalt and a composite warm-mix regenerant. The asphalt is new asphalt. The quality of asphalt binder is 10000g, wherein the content of new asphalt is 60%, that is 6000g, and the content of aged asphalt is 40%, that is 4000g. Composite warm-mix regeneration agent includes surfactant and oil regeneration agent. The surfactant is sorbitan fatty acid, which is a yellow, transparent, liquid substance at room temperature; the oil regeneration agent is heavy oil, which is a dark yellow, viscous liquid substance at room temperature.

[0081] The preparation of the above-mentioned composite warm mixing regenerant comprises the following steps:

[0082] (1) Sorbitan fatty acid and heavy oil are weighed according to a certain ratio.

[0083] The amount of fatty acid sorbitan added is 0.6% of the mass of asphalt binder, that is, P 脂肪酸山梨坦 =(P 1 +P 2 ) × A = 10000 × 0.6% = 60g; when the aged asphalt is regenerated to asphal...

Embodiment 3

[0091]A warm-mix regenerated asphalt is prepared by mixing asphalt and a composite warm-mix regenerant. The asphalt is new asphalt. The quality of asphalt binder is 10000g, wherein the content of new asphalt is 80%, that is 8000g, and the content of aged asphalt is 20%, that is 2000g. Composite warm-mix regeneration agent includes surfactant and oil regeneration agent. The surfactant is polysorbate, which is a yellow, transparent, liquid substance at room temperature; the oil regeneration agent is lubricating oil, which is a dark yellow, viscous liquid substance at room temperature.

[0092] The preparation of the above-mentioned composite warm mixing regenerant comprises the following steps:

[0093] (1) Take polysorbate and lubricating oil according to a certain ratio.

[0094] The amount of polysorbate added is 0.3% of the mass of asphalt binder, that is, P 聚山梨酯 =(P 1 +P 2 ) × A = 10000 × 0.3% = 30g; the experiment shows that when the aged asphalt is regenerated to as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com