Compound SBS (styrene butadiene styrene) modified asphalt and production process thereof

A technology of modified asphalt and production process, applied in building components, building insulation materials, buildings, etc., can solve problems such as affecting road construction quality, softening point reduction, performance attenuation, etc., to reduce development time, save time and cost, and improve Effects of softening point and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

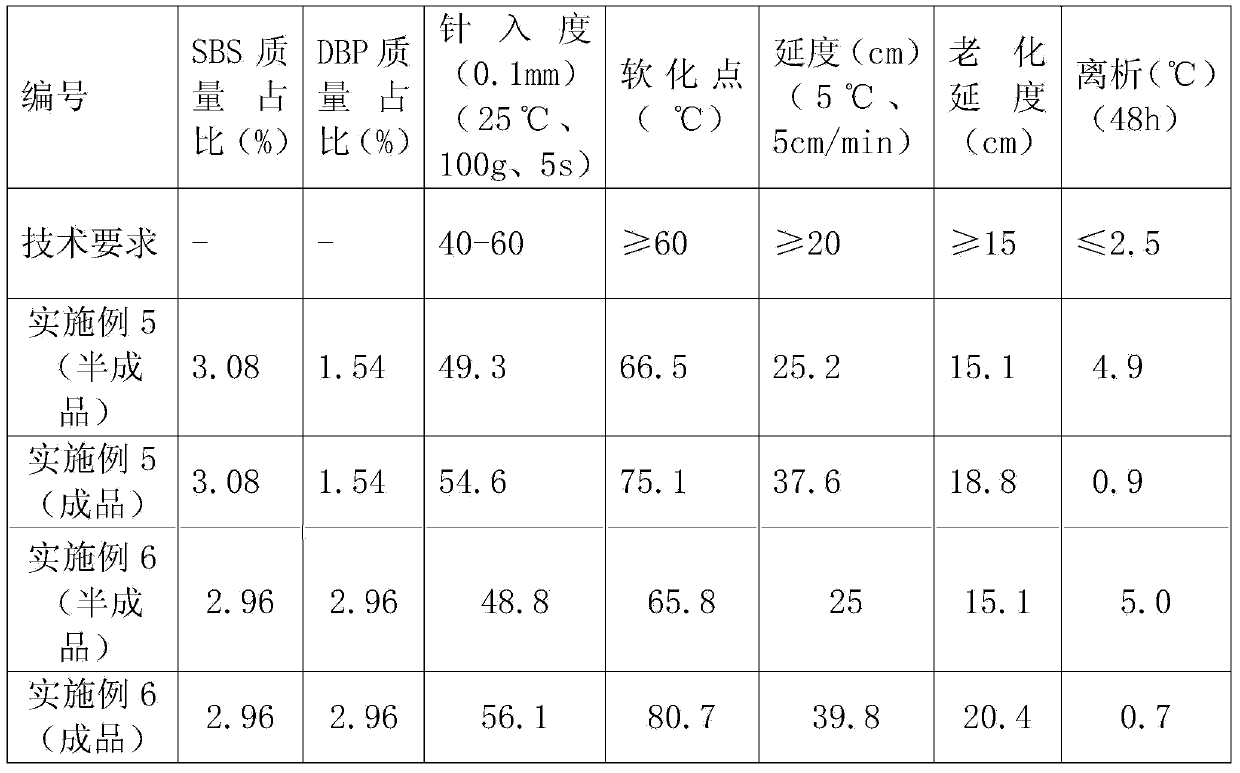

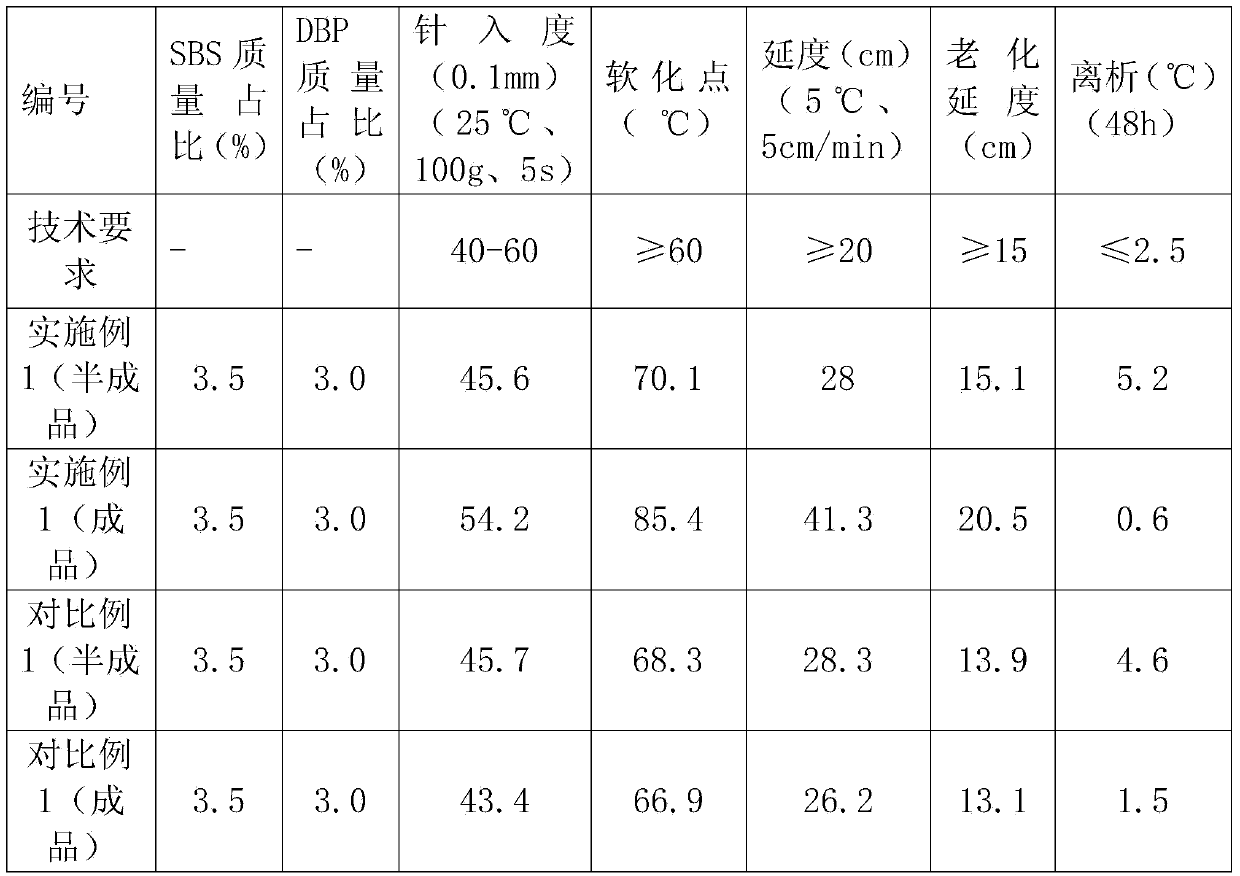

Embodiment 1

[0020] 1) Heat 6780kg of 70# base asphalt to 180°C to make it fully swell and become molten;

[0021] 2) Heat 2500kg of 50# base asphalt to 180°C to make it fully swell and become molten;

[0022] 3) Put the swollen 70# matrix asphalt into the working tank, add 350kg of star-shaped SBS, 300kg of dibutyl phthalate (DBP), and 50kg of rubber powder, stir evenly, and pass through the colloid mill for three times of high-speed shearing to obtain Mixture;

[0023] 4) Put the mixture into the development tank, develop at 180°C for 0.5h, add 20kg of sulfur and 2500kg of swollen 50# matrix asphalt, cool down to 170°C and develop for 0.5h, that is, the compound SBS modified asphalt semi-finished product , sampling inspection;

[0024] 5) Put the semi-finished product of SBS modified asphalt into the insulation tanker, and continue to grow during the process of transportation to the construction site. The transportation time is 12 hours. When the temperature drops by 5°C when it arriv...

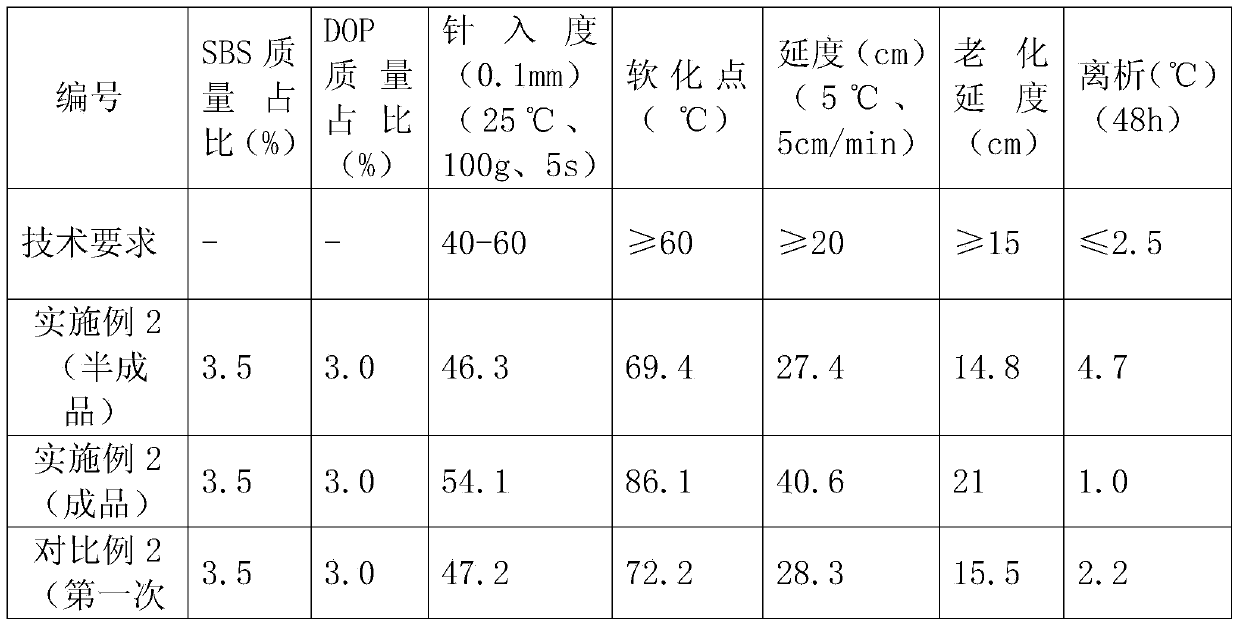

Embodiment 2

[0035] 1) Heat 6780kg of 70# base asphalt to 190°C to make it fully swell and become molten;

[0036] 2) Heat 2500kg of 50# base asphalt to 185°C to make it fully swell and become molten;

[0037] 3) Put the swollen 70# base asphalt into the working tank, add 350kg of linear SBS, 300kg of dioctyl phthalate (DOP), and 50kg of rubber powder, stir evenly, and pass through the colloid mill for three times of high-speed shearing to obtain Mixture;

[0038] 4) Put the mixture into the development tank, develop at 185°C for 1.5h, add 20kg of sulfur and 2500kg of swollen 50# matrix asphalt, cool down to 180°C and develop for 1.5h, which is the compound SBS modified asphalt semi-finished product;

[0039] 5) Put the SBS modified asphalt semi-finished product into the insulation tanker, and continue to grow during the transportation to the construction site. The transportation time is 16 hours. When the temperature drops by 5°C when it arrives at the site, the compound SBS modified a...

Embodiment 3

[0051] 1) Heat 6650kg of 70# base asphalt to 185°C to make it fully swell and become molten;

[0052] 2) Heat 2500kg of 50# base asphalt to 185°C to make it fully swell and become molten;

[0053] 3) Pour the swollen 70# matrix asphalt into the working tank, add 380kg of star-shaped and linear mixed SBS, 400kg of dioctyl phthalate (DOP), and 50kg of rubber powder, stir evenly, and pass through the colloid mill for high-speed shearing 3 times, to obtain the mixture;

[0054] 4) Put the mixture into the development tank, develop it at 185°C for 1 hour, add 20kg of sulfur and swollen 50# matrix asphalt, cool down to 175°C and develop it for 1 hour, then the compound SBS modified asphalt semi-finished product;

[0055] 5) Put the SBS modified asphalt semi-finished product into the insulation tanker, and continue to develop during the transportation to the construction site. The transportation time is 14 hours. When the temperature drops by 5°C when it arrives at the site, the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com