Fiber Cutter

A technology of fiber cutting machine and cutting mechanism, which is applied in the field of short fiber manufacturing, can solve the problems of cutting filament bundles into short fibers, reducing short fiber production efficiency, time-consuming and labor-intensive problems, and achieves high cutting precision, simple structure and convenient manufacture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

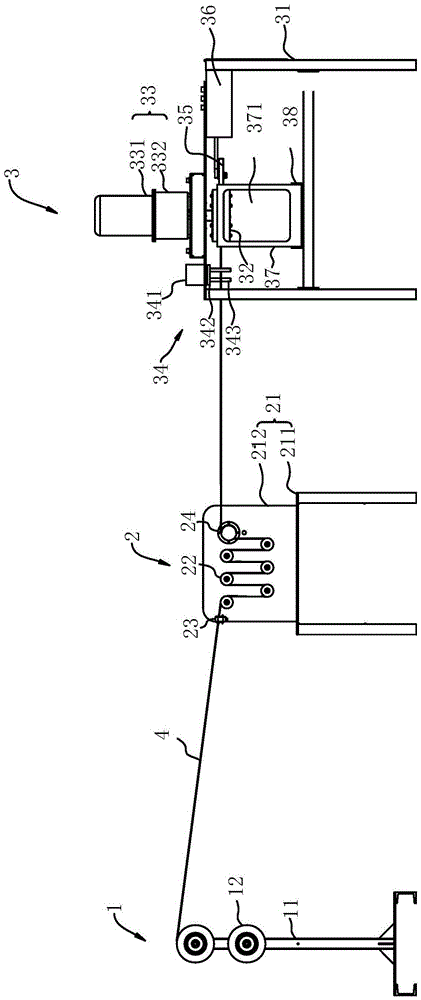

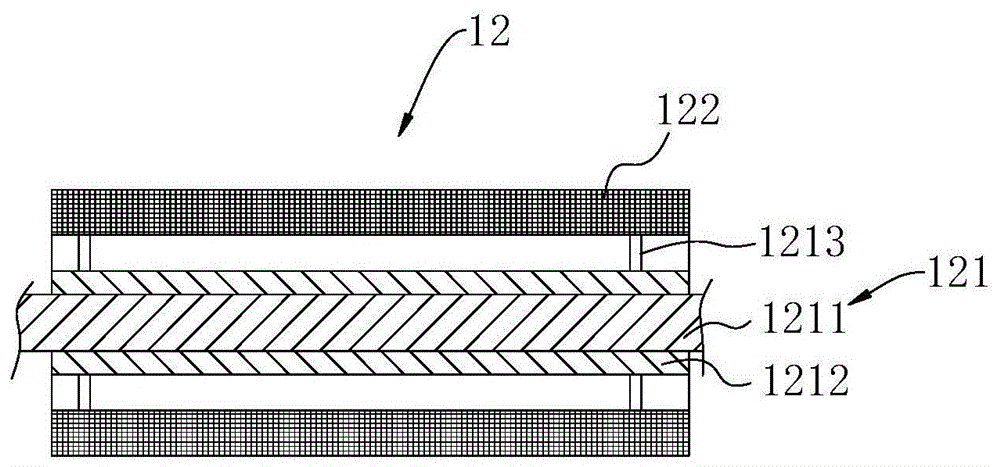

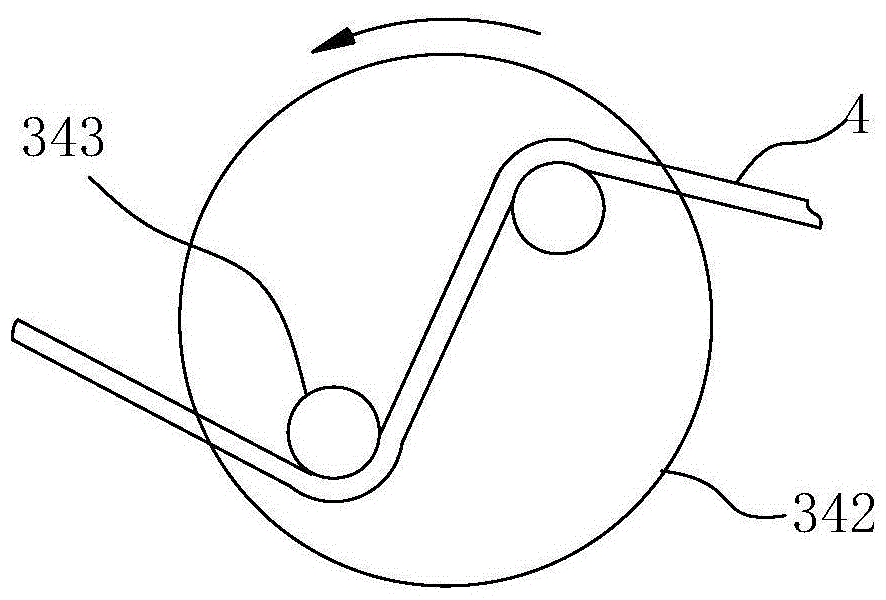

[0041] Such as figure 1As shown, a fiber cutting machine described in this embodiment includes a wire wheel mechanism 1, a cutting mechanism 3 and a tensioning mechanism 2 between the wire wheel mechanism 1 and the cutting mechanism 3. The wire wheel mechanism 1 includes a wire wheel fixed Frame 11 and at least one wire wheel part 12 fixed on the fixed frame 11, the wire wheel part 12 includes a wire wheel 121, and the outside of the wire wheel 121 is sleeved with a tow cover 122 composed of long tows 4 to be cut, and the cutting mechanism 3 includes a frame 31, a cutterhead 32 for cutting the filament bundle 4 into short fibers, a first power unit 33 for driving the cutterhead 32 to rotate, and a press for pressing the filament bundle 4 on the cutterhead 32. Wheel 35 and the tension adjusting devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com