A cold storage delivery door structure

A cold storage and door panel technology, applied in door/window fittings, building structures, power control mechanisms, etc., can solve the problems of easy waiting for goods outside the door, low work efficiency, accumulation, etc., to avoid a large number of leakage and save switches time, the effect of increased efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

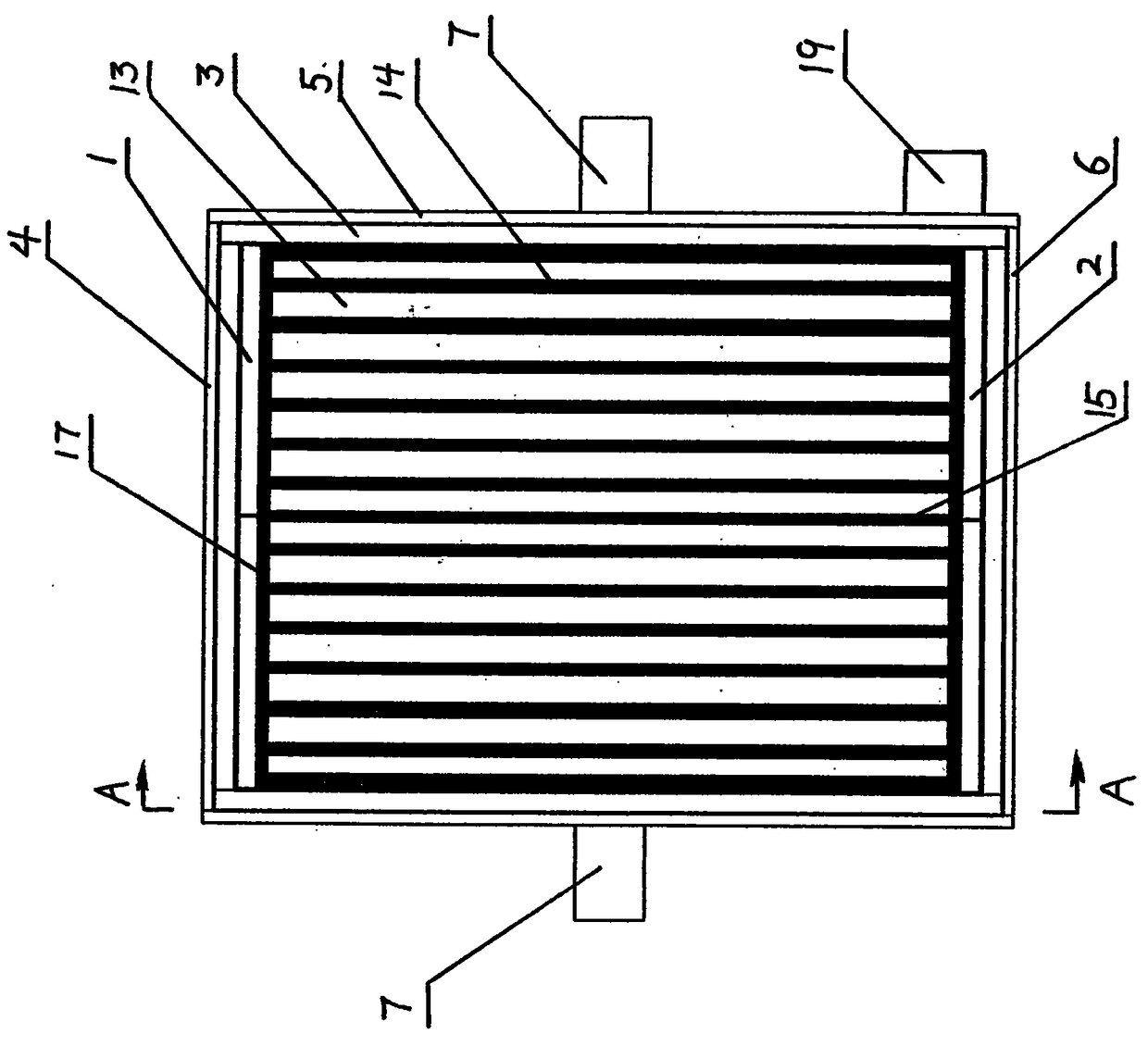

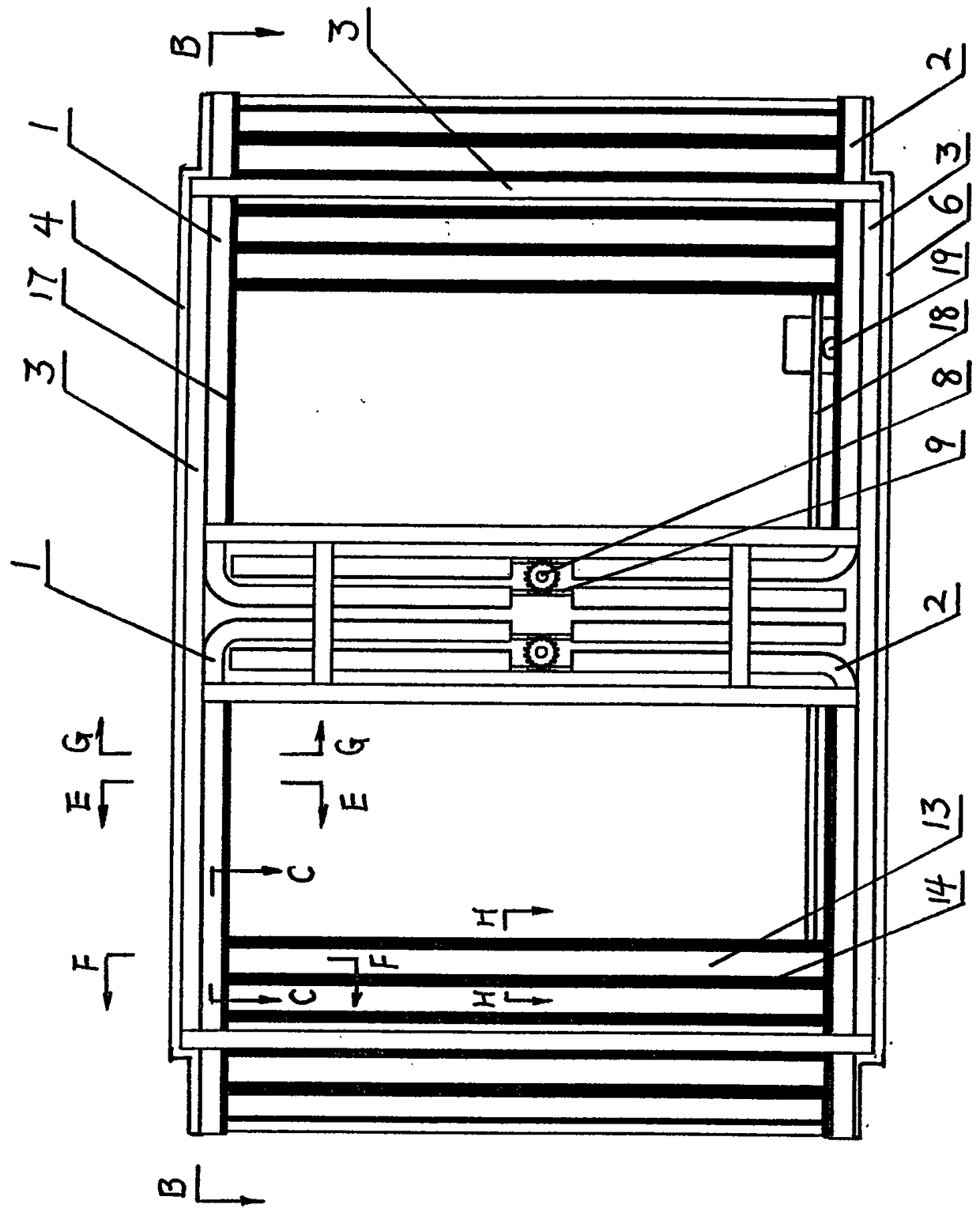

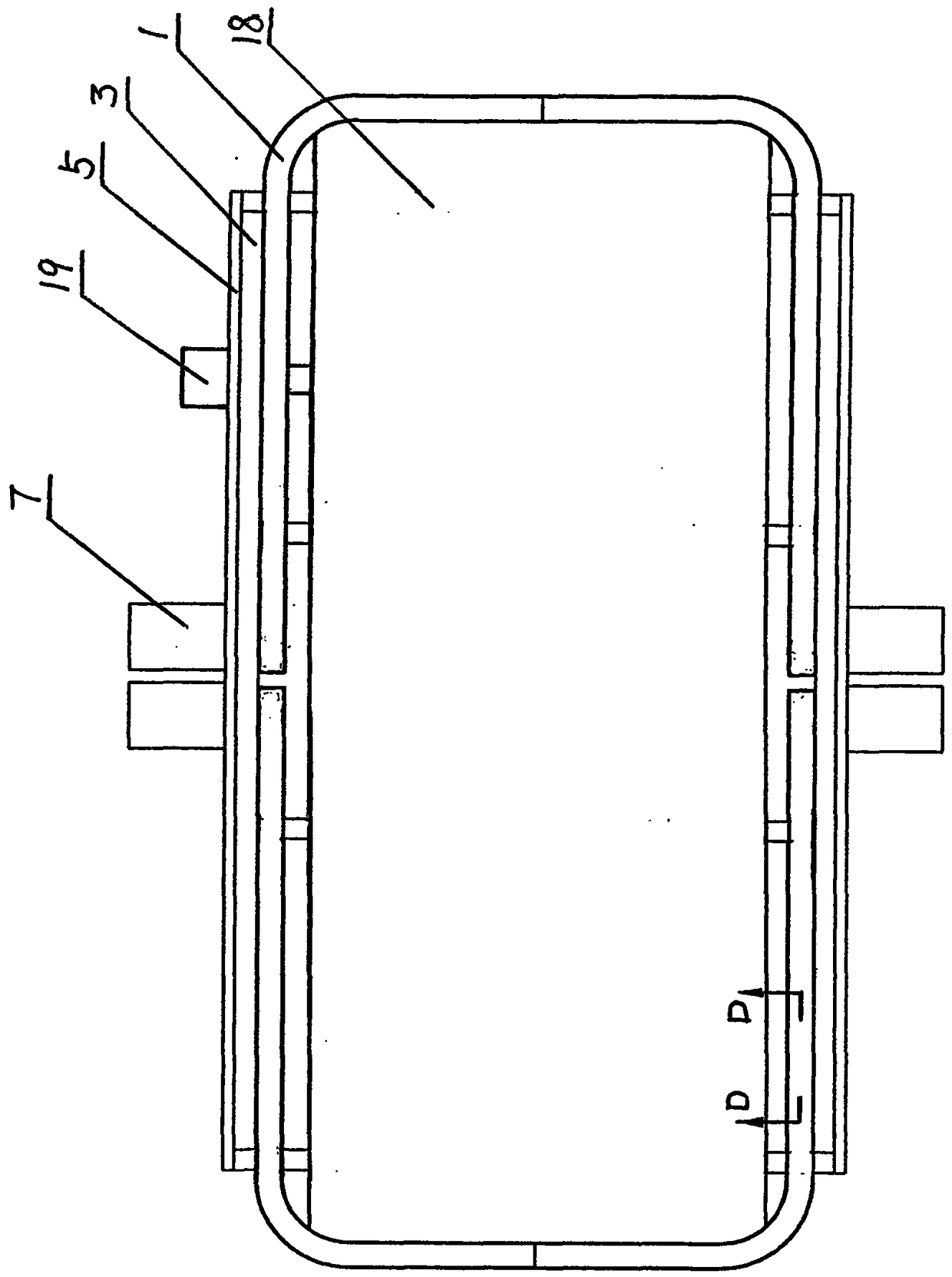

[0026] Such as Figure 1 to Figure 9 Shown, this cold storage delivery door structure of the present invention consists of upper chain guide rail 1, lower chain guide rail 2, main body frame 3, top plate 4, side plate 5, bottom plate 6, sprocket motor 7, sprocket wheel 8, transmission chain 9, Drive chain 10, chain connecting block 11, connecting pin shaft 12, door panel 13, telescopic connector 14, extrude sealing strip 15, anti-cold bridge connector 16, insulation strip 17, conveyor belt 18, transmission motor 19 to form, will The upper chain guide rail 1 is installed on the upper part of the main frame 3, the lower chain guide rail 2 is installed on the lower part of the main frame 3; the top plate 4 is installed on the upper part of the main frame 3, and the side plate 5 is installed on the upper part of the main frame On both sides of the main body frame 3, the bottom plate 6 is installed on the bottom of the main frame 3; the sprocket motor 7 is installed on the side pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com