Air-heated vaporizer and use method thereof

A technology of air-temperature vaporizer and gasification tube, which is applied in the direction of container discharge, pressure vessel, fixed-capacity gas storage tank, etc., and can solve the problem of damage to equipment sealing and parts strength, poor corrosion resistance of equipment, and use Short service life and other problems, to achieve the effect of improving service life and safety, low cost, and improved appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

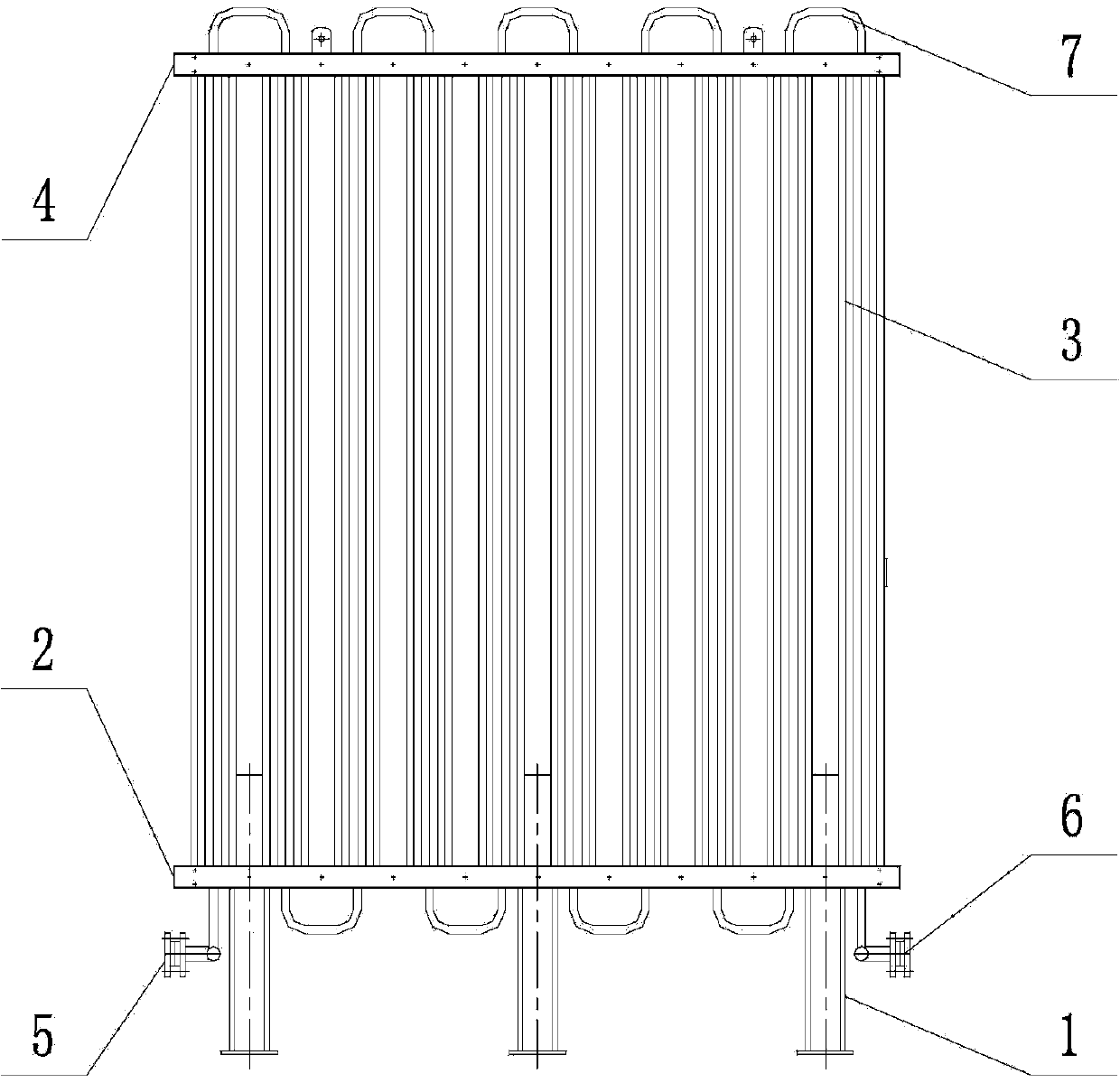

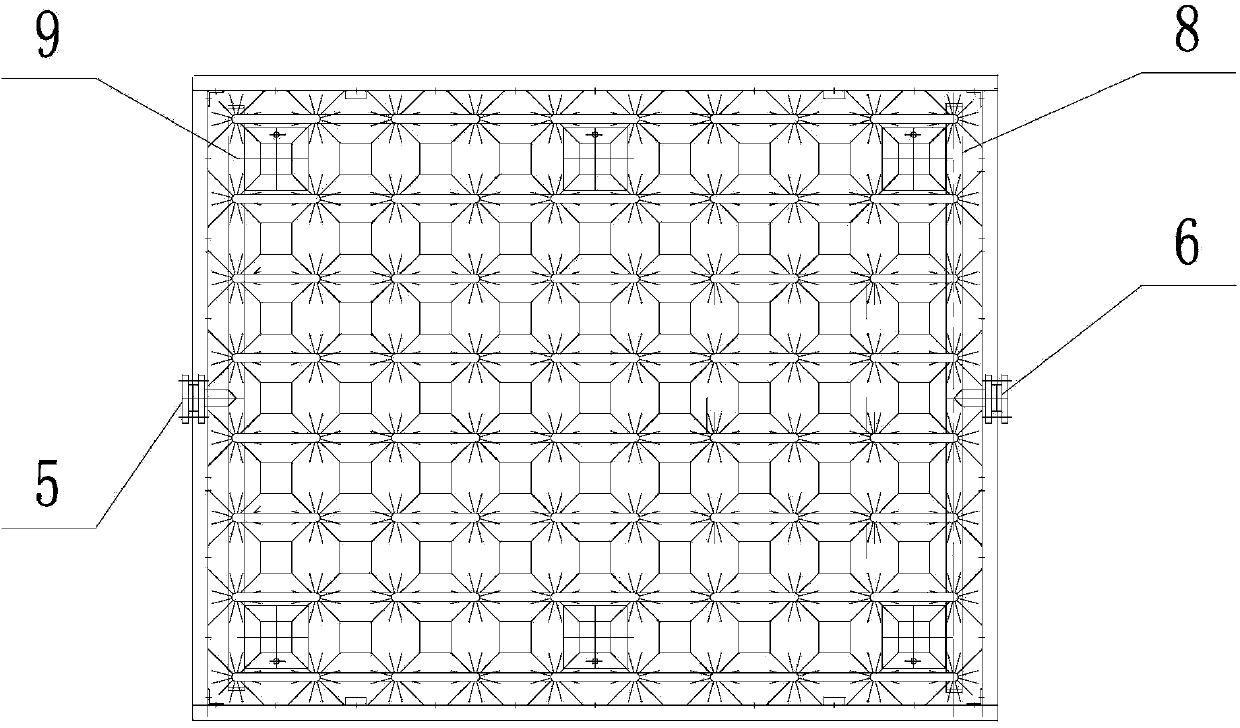

[0036] Such as figure 1 with figure 2 As shown, the air-heated gasifier provided in this embodiment includes a leg 1 arranged on a horizontal plane and a lower trough aluminum frame 2 horizontally arranged on the leg 1, and the lower trough aluminum frame 2 is horizontally arranged above the lower trough aluminum frame 2. A gasification space is formed between the aluminum frames 4 in the upper trough, and a serpentine gasification pipe 7 is arranged in the gasification space. Pass through the aluminum frame 4 of the upper groove from the lower direction, and pass through the aluminum frame 2 of the lower groove vertically again after bending. Each serpentine gasification tube 7 is a gasification group, and the gasification space includes 8 groups of gasification groups arranged in parallel with each other;

[0037] The inlet and outlet of each group of gasification groups are located under the aluminum frame 2 of the lower tank and correspond to the positions respectively. T...

Embodiment 2

[0040] The structure of the air-temperature vaporizer in this embodiment is the same as that in Embodiment 1, and the method of using the air-temperature vaporizer in this embodiment is as follows:

[0041] Step (1): Apply high-chlorinated polyethylene anti-corrosion paint on the surface of the aluminum parts involved in the air-heated gasifier, with a thickness of 2mm, cool at room temperature for 20 minutes, and paint the thickness of high-chlorinated polyethylene anti-corrosion paint again 3mm, cool at room temperature for 50 minutes, and finally apply high-chlorinated polyethylene anti-corrosion paint with a thickness of 5mm, and then proceed to step (2) after cooling at room temperature for 20 hours;

[0042] Step (2): Introduce water with a pressure of 0.5Mpa and a temperature of 60°C into the vaporizer pipeline for 40 minutes, and check whether the sealing is intact, then inject nitrogen with a flow rate of 20m / s, and paint with white paint The wooden target board is pa...

Embodiment 3

[0045] The structure of the air-temperature vaporizer in this embodiment is the same as that in Embodiment 1, and the method of using the air-temperature vaporizer in this embodiment is as follows:

[0046] Step (1): Apply high-chlorinated polyethylene anti-corrosion paint on the surface of the aluminum parts involved in the air-temperature gasifier, with a thickness of 2.5 mm, cool at room temperature for 25 minutes, and then apply high-chlorinated polyethylene anti-corrosion paint again The thickness is 4mm, cooled at room temperature for 55 minutes, and finally the thickness of the high-chlorinated polyethylene anti-corrosion paint is 6mm, and the step (2) is carried out after cooling at room temperature for 22 hours;

[0047] Step (2): Introduce water with a pressure of 0.6Mpa and a temperature of 70°C into the vaporizer pipeline for 45 minutes, and check whether the sealing is intact, then inject nitrogen with a flow rate of 30m / s, and paint with white paint The wooden ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap