Heat source machine formed by connecting gas water heaters in parallel and control method

A gas water heater and water heater technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of large boiler system, unstable water temperature, and high investment cost, and achieve simple system structure and constant water temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

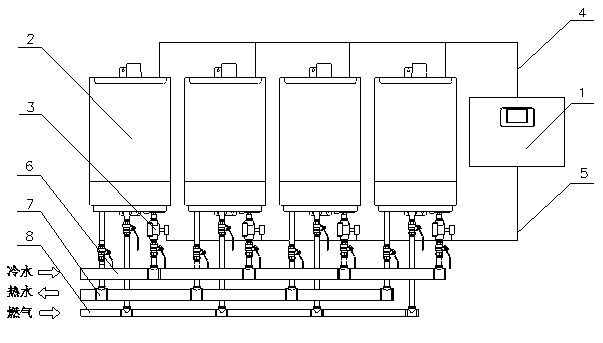

[0020] Such as figure 1 As shown, a heat source machine in which gas water heaters are connected in parallel includes a main water inlet pipe 6, a hot water converging pipe 7, a main gas inlet pipe 8, a plurality of gas water heaters 2 and a system controller 1, and the plurality of gas water heaters 2 pass through The total water inlet pipe 6, the hot water converging pipe 7, and the total gas inlet pipe 8 are connected in parallel; each water heater is equipped with a collection water flow sensor, an inlet water temperature detector and an outlet water temperature detector, and the communication bus 4 and the setting The signal converter on the communication bus 4 is connected to the system controller 1, and the cold water pipe of the gas water heater 2 is provided with a water inlet solenoid valve 3, and the water inlet solenoid valve 3 is connected to the system control through the water inlet switch control line 5. Connector 1.

[0021] Such as figure 1 As shown, the ...

Embodiment 2

[0036] In this example, four Qianfeng brand JSQ36-F7 intelligent constant-temperature forced-vent gas rapid water heaters are used to form a heat source machine. The maximum hot water production capacity of a single water heater is 18kg / min (at a temperature rise of The hot water production capacity is 2kg / min (at a temperature rise of 25°C). Therefore, the maximum hot water production capacity of this heat source unit is 4x18=72kg / min (at a temperature rise of 25°C).

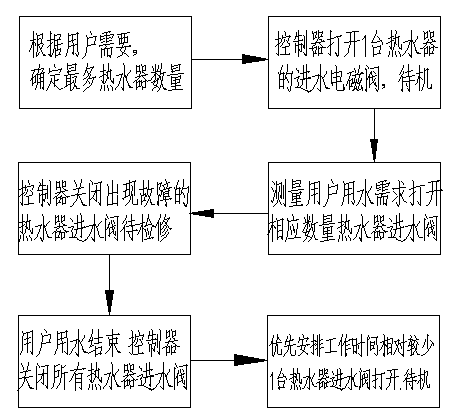

[0037] The control process of the heat source machines formed by gas water heaters connected in parallel in this embodiment is:

[0038] First, according to the user's needs, set the required hot water temperature to 45°C through the system controller. The tap water temperature of the user is 20°C, therefore, the water inflow of each gas water heater is just numerically the same as the hot water production capacity of the water heater. According to the situation of the user's system, the system controller fir...

Embodiment 3

[0048] In this example, four Qianfeng brand JSQ36-F7 intelligent constant-temperature forced-vent gas rapid water heaters are used to form a heat source machine. The maximum hot water production capacity of a single water heater is 18kg / min (at a temperature rise of The hot water production capacity is 2kg / min (at a temperature rise of 25°C). Therefore, the maximum hot water production capacity of this heat source unit is 4x18=72kg / min (at a temperature rise of 25°C).

[0049] The control process of the heat source machines formed by gas water heaters connected in parallel in this embodiment is:

[0050] First, according to the user's needs, set the required hot water temperature to 45°C through the system controller. The tap water temperature of the user is 20°C, therefore, the water inlet flow of each water heater is just numerically the same as the hot water production capacity of the water heater. According to the situation of the user's system, the system controller fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com