Specific stationary fixture for detecting wave buoy

A technology of wave buoys and fixed fixtures, which can be used in measuring devices, surveying and navigation, open-air water source surveys, etc., can solve the problems of enlarged safety hazards, different lengths, lack of equipment, etc., and achieve the effect of improving safety performance and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

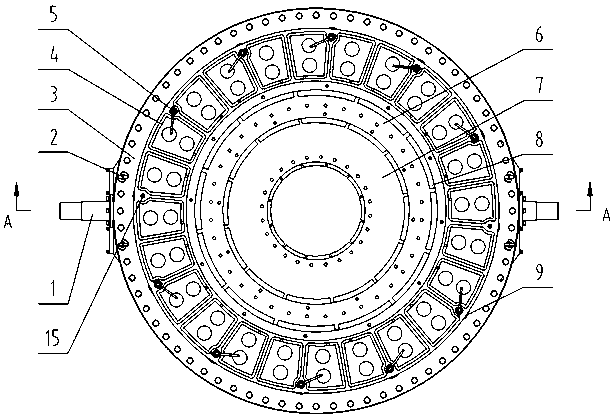

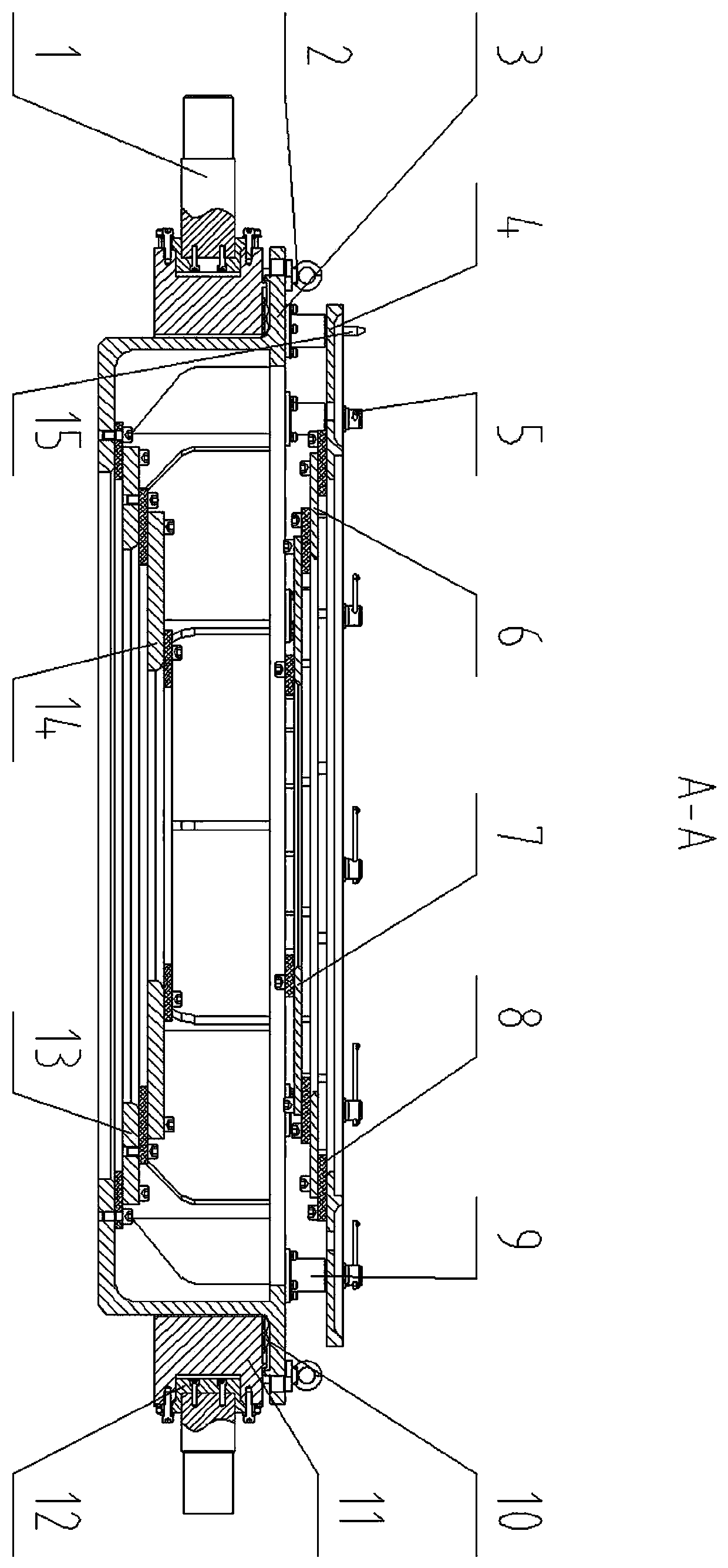

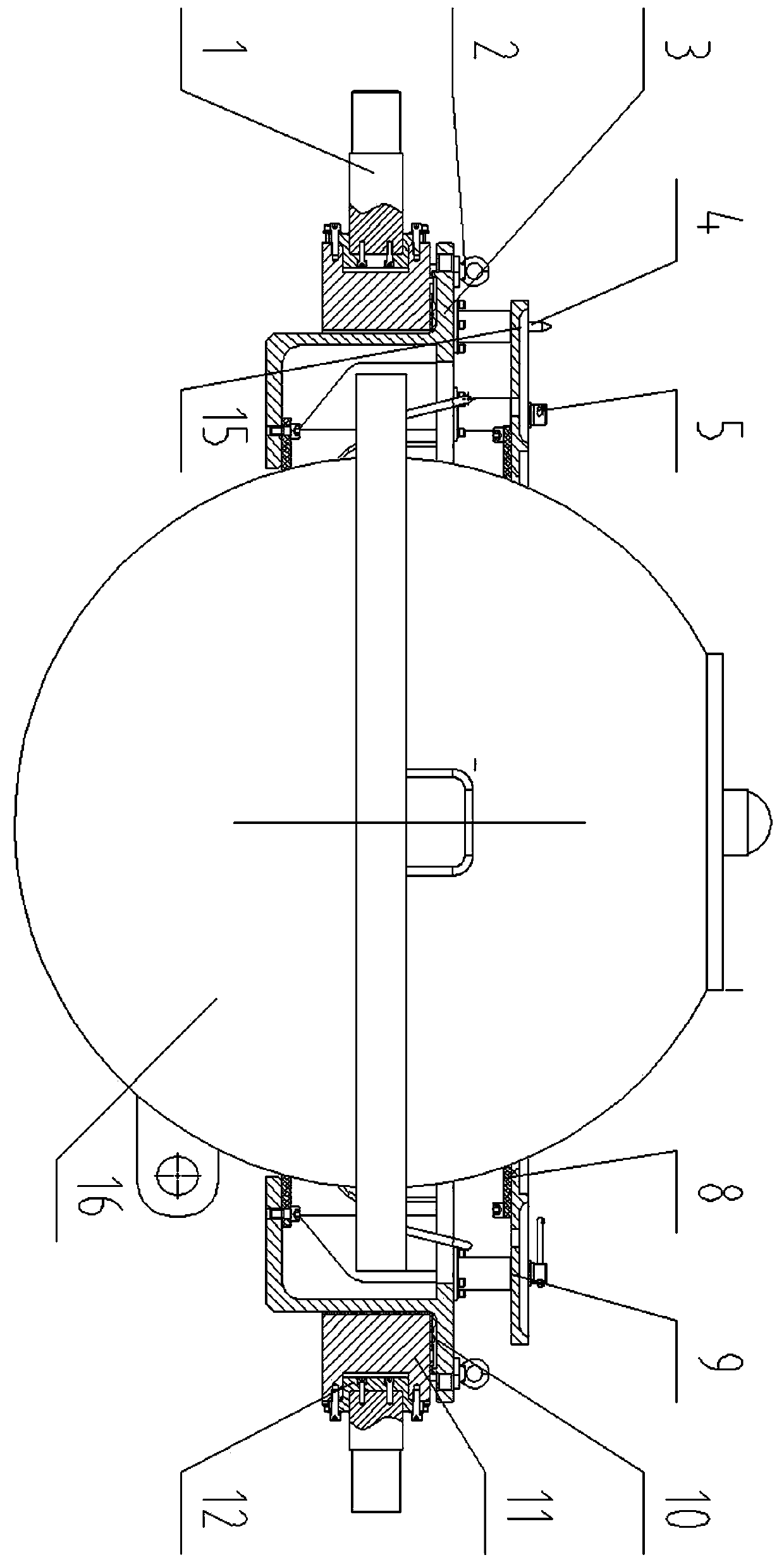

[0019] Below in conjunction with accompanying drawing, the technical scheme of the present application is described in detail:

[0020] like figure 1 As shown, the special fixing fixture for wave buoy detection includes rotating shaft 1, azimuth positioning pin 2, rotating body seat 3, buoy upper pressure plate, fixing bolt 5, rubber gasket 8, screw sleeve 9, azimuth turntable 11, and rotating shaft flange 12. The lower pressure plate of the buoy and the positioning pin 15, wherein the rotating shaft 1 and the rotating shaft flange 12 are coaxially installed on both sides of the azimuth turntable 11 after assembly; 2 Lock the position of the rotating body seat 3; after the upper pressure plate of the buoy is assembled with the rubber gasket 8, it is fixed on the upper part of the rotating body seat 3 through the fixing bolt 5 and the screw sleeve 9, and the rotating body is locked by the positioning pin 15 The position on the seat 3; the lower pressure plate of the buoy is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com