Test method of slippage rate of tractor

A test method and slip rate technology, applied in wheel testing and other directions, can solve problems such as increased fuel consumption, engine power consumption, agricultural production loss, etc., and achieve the effect of improving accuracy and measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

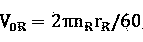

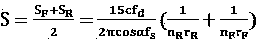

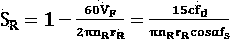

[0042] like figure 1 , 4 , 5, 6, 7, and 8 show that when the tractor is working in the field, the power system composed of the diesel engine and the tractor to be tested and the resistance system composed of the plow unit. The front and rear wheel speeds are measured by the front wheel photoelectric encoder and the rear wheel photoelectric encoder. For a four-wheel drive tractor, when driving straight, the wheels will have different slip rates due to factors such as size, load and soil conditions, but the same axle The difference in the slip rate of the left and right wheels is relatively small, and only the front and rear wheels on the same side need to be measured; the low-speed radar sensor measures the forward speed of the vehicle, the load sensor on the upper rod and the load sensor on the lower rod measure the traction force of the vehicle, and the strain gauge measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com