A Surface Defect Detection Method Based on Visual Saliency Map and Support Vector Machine

A support vector machine and defect detection technology, applied in the field of surface defect detection, can solve the problems of high labor intensity, subjective factors of inspectors, low work efficiency, etc., and achieve the effect of high classification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

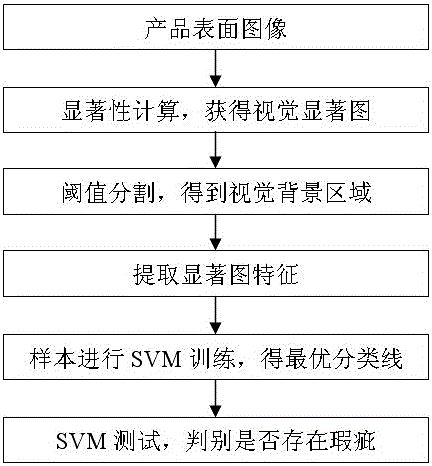

[0024] Embodiment one: see figure 1 As shown, a surface defect detection method based on visual saliency map and support vector machine includes the following steps:

[0025] (1) Extracting features from the visual saliency map:

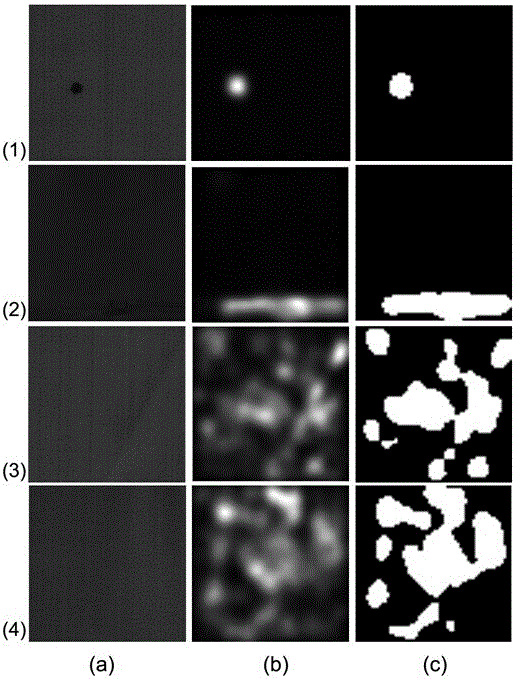

[0026] (1) For 250 surface image samples of the product to be tested, the GBVS model is used to calculate their respective visual saliency maps; figure 2 As shown in (a), it represents the original cloth image. By extracting the brightness feature and direction feature, the visual saliency map of each image is obtained by using the GBVS model ,Such as figure 2 (b) shown.

[0027] (2) Through the maximum between-class variance method (OTSU), the visual saliency map obtained in step (1) is subjected to adaptive threshold segmentation to obtain a binary image , to extract its visual background area, such as figure 2 as shown in (c);

[0028] Let the grayscale in the image be The number of pixels is , the grayscale range is Pixels in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com