Flame-retardant and fire-retardant cable with high performance

A flame-retardant, fire-resistant, high-performance technology, applied in the field of high-performance flame-retardant and fire-resistant optical cables, can solve problems that affect the use of optical cables and cannot guarantee high-performance flame-retardant optical cables, and achieve protection against fire threats, good heat insulation, and improved resistance The effect of the fire safety performance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

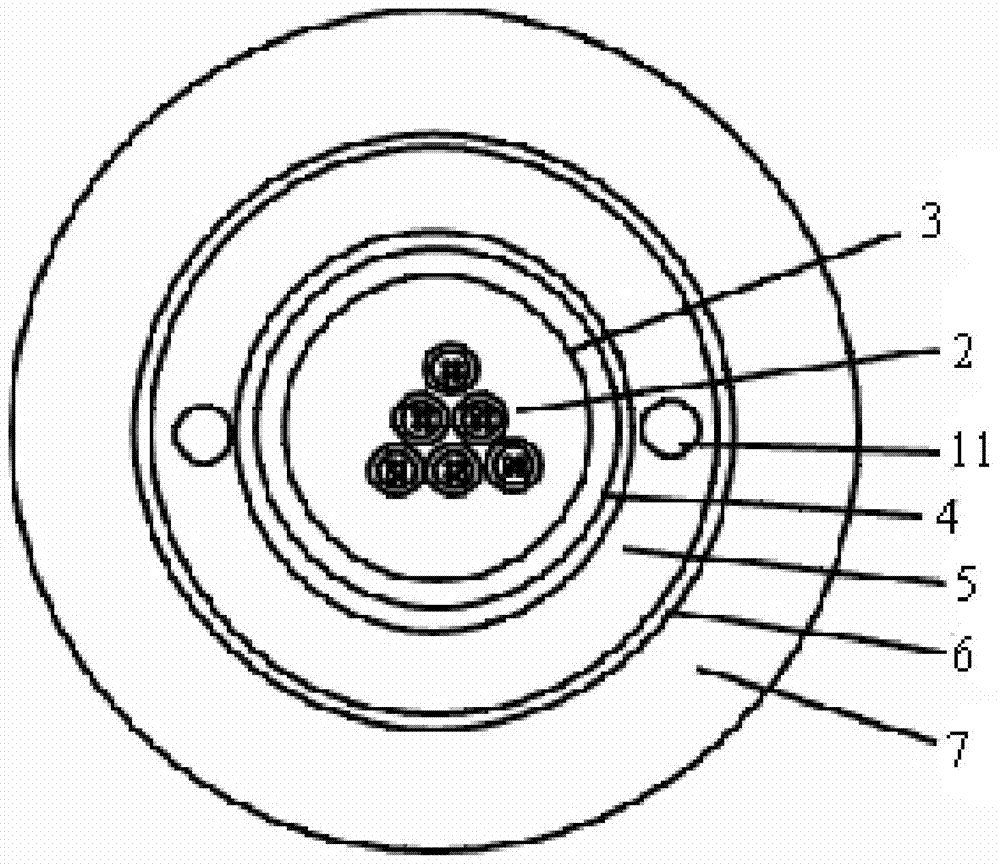

[0034] Such as figure 1 As shown, the present invention includes a cable core, a reinforcing member 11 and a protective layer, and the protective layer is coated on the outside of the cable core and the reinforcing member 11, wherein the protective layer is composed of a water blocking tape 3, a ceramic fiber tape 4, an inner sheath 5, The mica tape 6 and the outer sheath 7 are formed, the outer sheath 7 is the outermost layer of the protective layer, the inner sheath 5 and the mica tape 6 are sequentially arranged between the ceramic fiber tape 4 and the outer sheath 7 from the inside to the outside, and the cable The core is a freely twisted micro-bundle tube 2, and there are two reinforcing members 11 embedded in the inner sheath 5 in parallel.

[0035] In the overall structure of this embodiment, ceramic fiber high-performance flame-retardant materials are used to longitudinally wrap micro-bundle tubes, and two flame-retardant inner sheaths embedded with two non-metallic m...

Embodiment 2

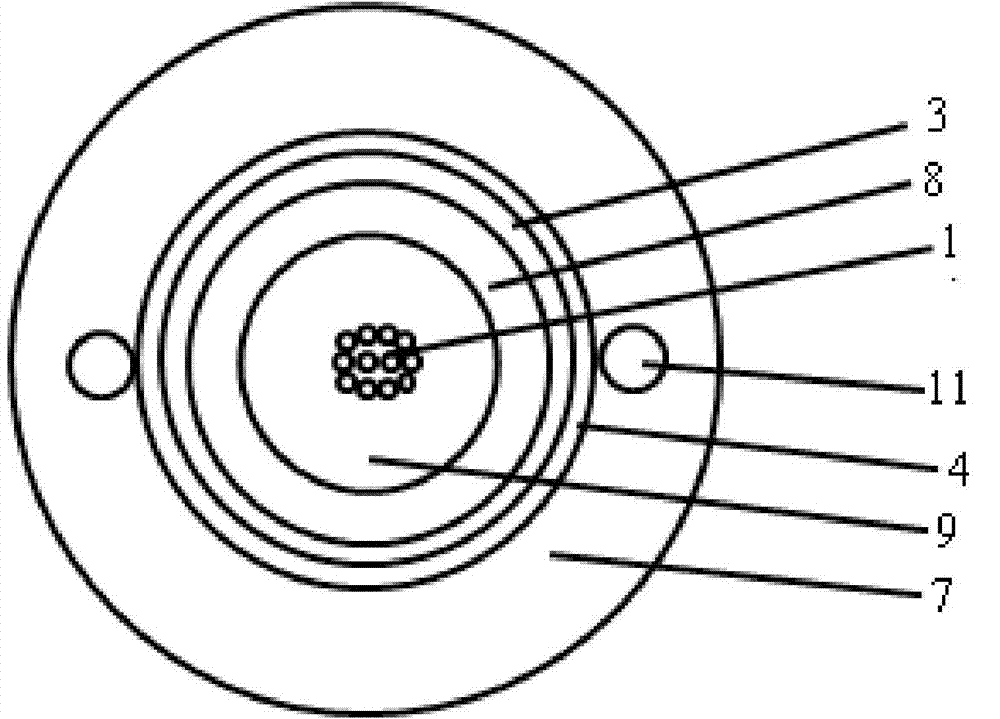

[0037] Such as figure 2 As shown, the present invention includes a cable core, a reinforcing member 11 and a protective layer, and the protective layer is coated on the outside of the cable core and the reinforcing member 11, wherein the protective layer is composed of a water blocking tape 3, a ceramic fiber tape 4 and an outer sheath 7, The outer sheath 7 is the outermost layer of the protective layer, the cable core is a loose tube 8 structure, the optical fiber 1 is placed inside the loose tube 8 and filled with fiber paste 9, and there are two strength members 11, which are embedded in the outer sheath 7 in parallel .

[0038] This embodiment adopts the all-dielectric structure design, which has obvious lightning protection effect, avoids the accident rate of lightning when the existing local telephone pole road is directly laid indoors, and brings convenience to the popularization and construction of optical cables.

Embodiment 3

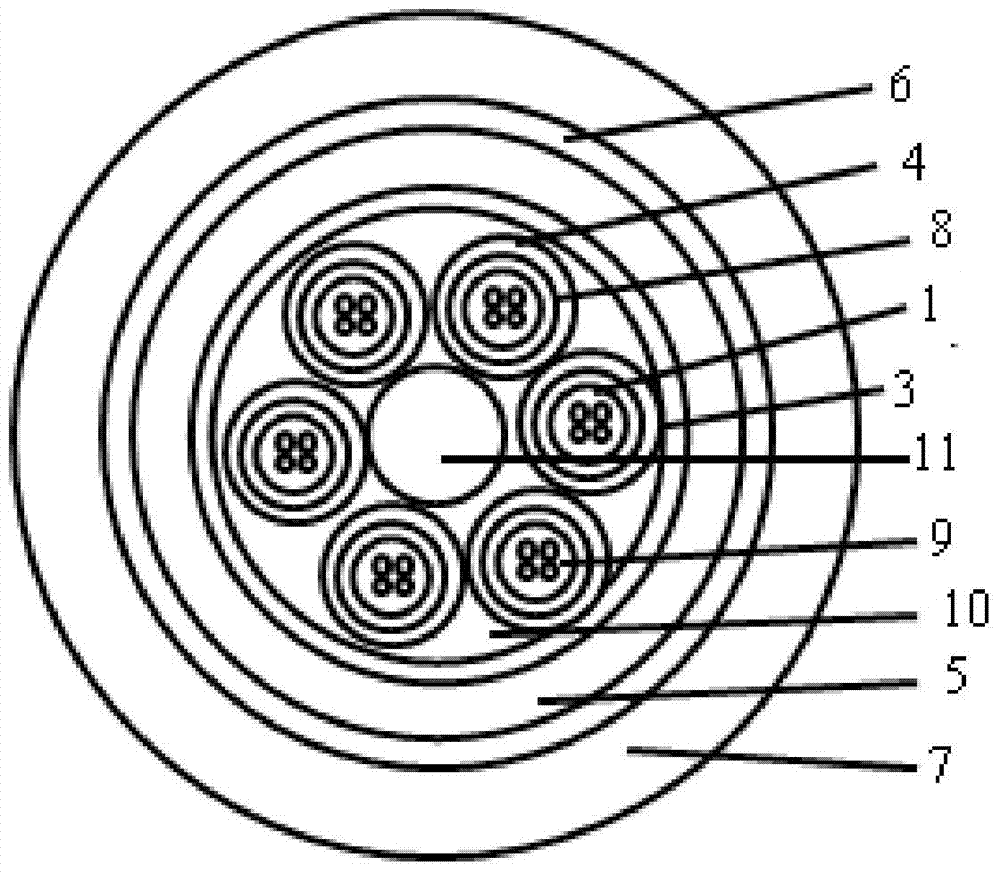

[0040] Such as image 3As shown, the present invention includes a cable core, a reinforcing member 11 and a protective layer, and the protective layer is coated on the outside of the cable core and the reinforcing member 11, wherein the protective layer is composed of a water blocking tape 3, an inner sheath 5, a mica tape 6, ceramic fiber The belt 4 and the outer sheath 7 are formed, and the outer sheath 7 is the outermost layer of the protective layer. The inner sheath 5 and the mica belt 6 are sequentially arranged between the water blocking belt 3 and the outer sheath 7 from the inside to the outside. The cable core is a loose tube 8 structure, which is composed of at least three loose tubes 8. The optical fiber 1 is placed inside the loose tube 8 and filled with fiber paste 9. The loose tube 8 is covered with a ceramic fiber tape 4 and a water blocking tape 3. It is coated on the outside of the loose tube 8, the cable paste 10 is filled between the loose tubes 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com