Semiconductor laser driving source with temperature compensation

A technology of laser driving and temperature compensation, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve problems such as not having temperature compensation functions, and achieve fast switching speed, reduced turn-off overshoot, and low shell inductance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

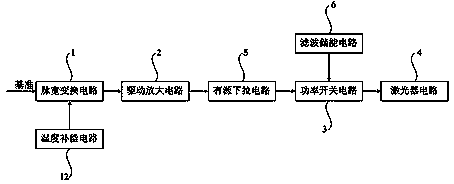

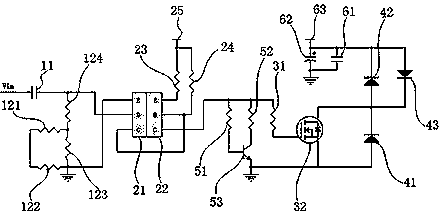

[0051] Such as figure 1 and figure 2 As shown, a semiconductor laser drive source with temperature compensation includes: a pulse width conversion circuit 1, a drive amplifier circuit 2, a power switch circuit 3, and a laser circuit 4 connected sequentially; 3 between the active pull-down circuit 5; a filter tank circuit 6, connected to the power switch circuit 3; wherein, the active pull-down circuit 5 includes a first resistor 51, a second resistor 52, a first triode 53 One end of the first resistor 51 is connected to the base of the first triode 53, and the other end is respectively connected to one end of the second resistor 52, the drive amplifier circuit 2, and the power switch circuit 3; the second resistor 52 The other end of the first triode 53 is connected to the collector; the emitter of the first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com