High-voltage transmission line linear tower electrified operation overhead ground wire lifting device

A technology for high-voltage transmission lines and straight-line iron towers, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of large tool quality, increased safety hazards, complicated fixing and binding, etc., achieve reasonable structural design, reduce working hours, and reduce work risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

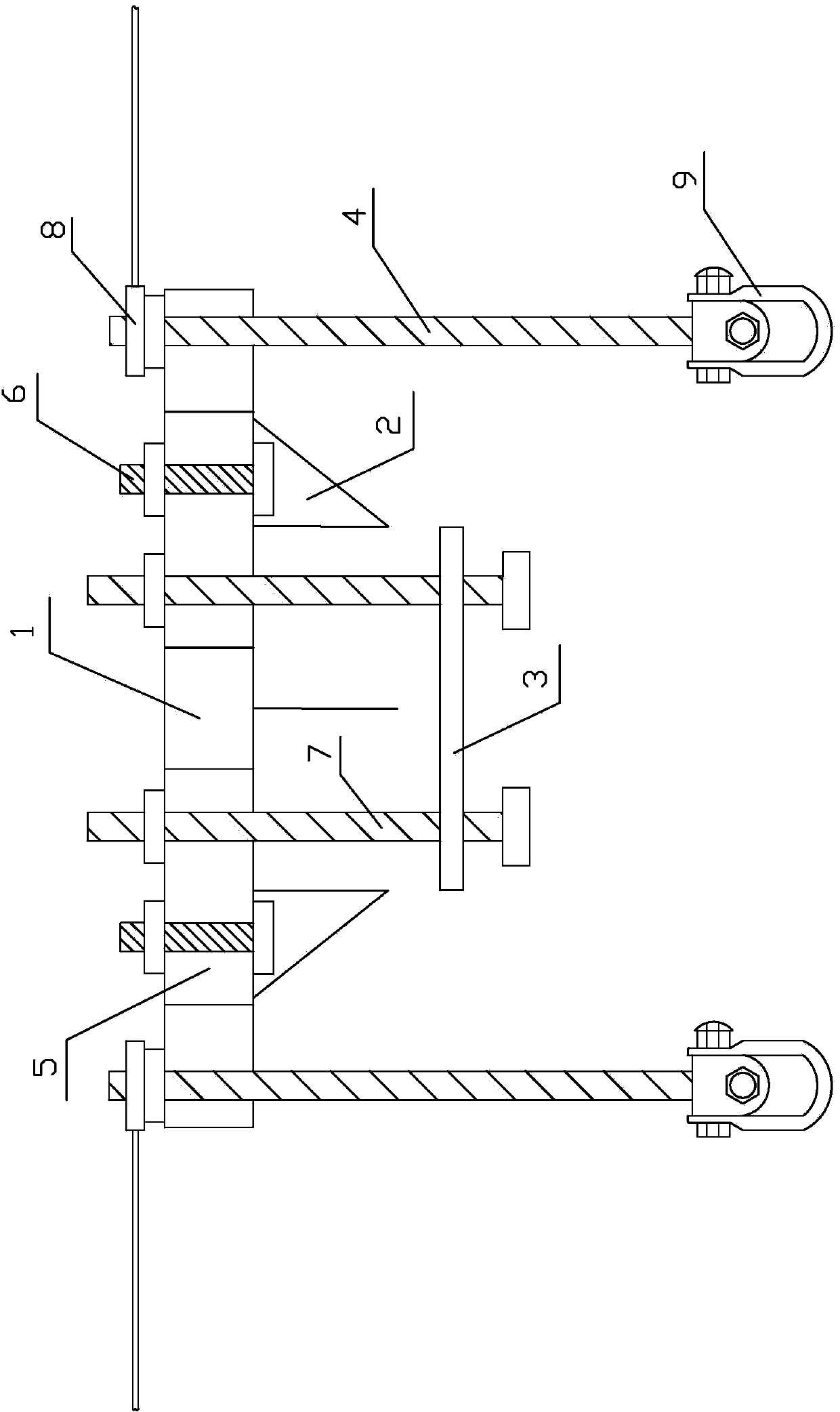

[0016] The lifting device for the overhead ground wire of the linear type iron tower of the high-voltage transmission line of the present invention includes a main board 1 , a clamping plate 2 , a clamping plate 3 and a lifting screw 4 .

[0017] The main board 1 is made of aluminum alloy material, and its length is greater than or equal to 1440mm. Its two sides are symmetrically provided with left and right strip bolt grooves 5, and the width of the strip bolt groove 5 is selected according to the bolt size. The two ends of the main board 1 on the outside of the groove 5 are symmetrically provided with left and right perforations, such as figure 1 shown.

[0018] The positioning plate 2 is a left and right right-angled inverted triangle plate, and the left and right right-angled inverted triangle plate is arranged below the main board 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com