Wire slot mold for multiwire windings

A wire slot and winding technology, which is applied in the field of wire slot moulds for multi-wire windings, can solve the problems of low winding current carrying capacity and small winding ampere turns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

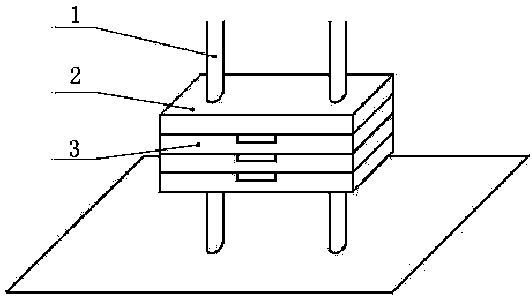

[0011] Such as figure 1 As shown, a slotting mold for multi-wire winding, which includes a bracket 1, several slotting plates 3 and a pressure plate 2, the slotting plate 3 is provided with slots, and several slotting plates 3 are stacked neatly and then installed to the bracket 1, and the notches of the wire grooves on the wire groove plate 3 are all facing upwards, and the wire groove plate 2 is also provided on the bracket, and the wire pressure plate 2 is closely attached to the upper surface of the uppermost wire groove plate, and the Notch cover in terminal trunking plate.

[0012] In specific applications, several enameled wires that need to be wound are layered through the wire grooves on the wire groove plate. The wire groove width on the wire groove plate is consistent with the thickness of the winding, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com