Electric motor control cabinet for pumping unit

A motor and control cabinet technology, applied in motor generator control, motor generator/starter, control system, etc., can solve problems such as salt and alkali resistance, poor corrosion resistance, underground failure, and increase production costs, and achieve resistance to The effect of strong corrosion and salinity resistance, improving maintenance efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

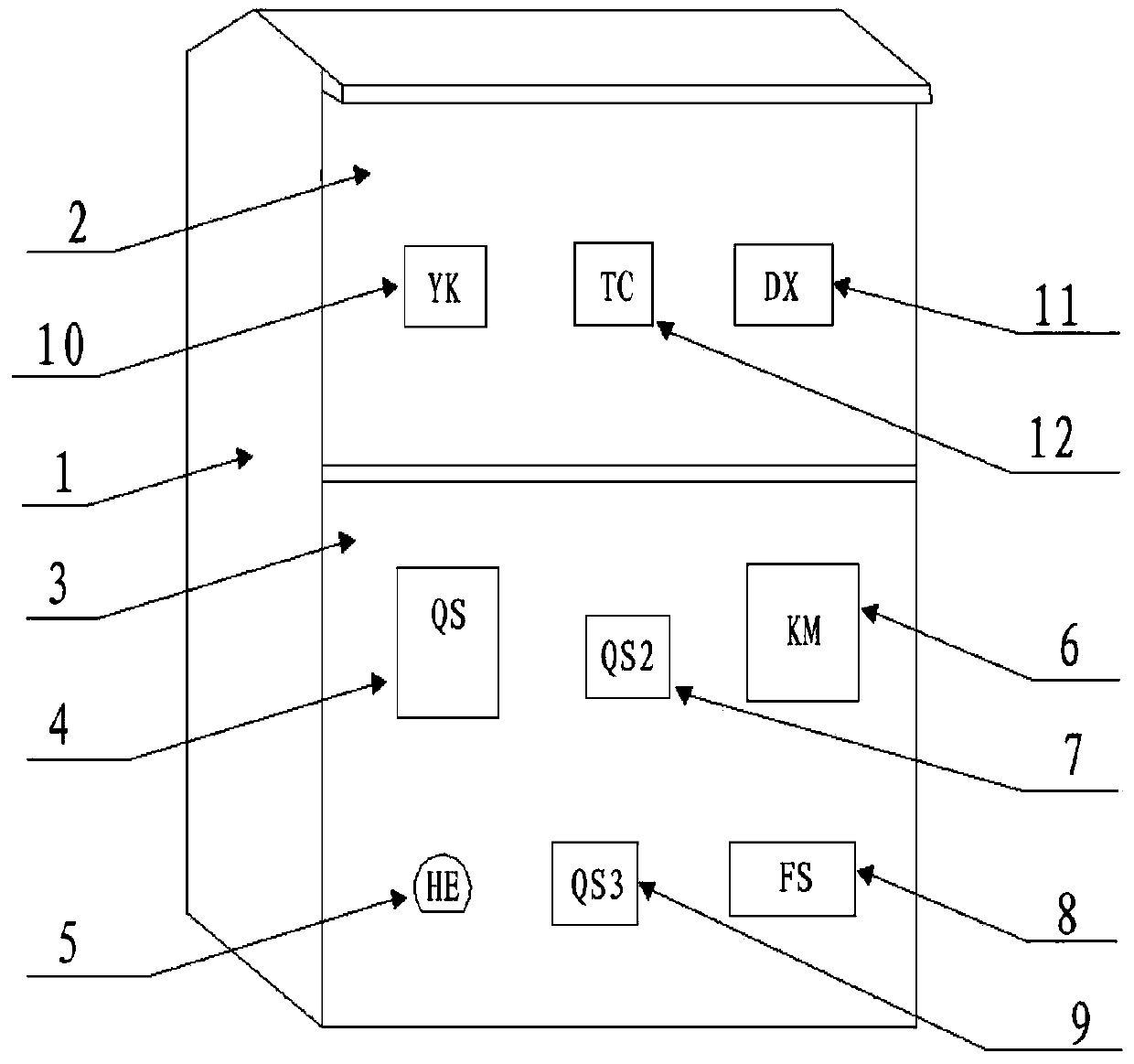

[0028] see figure 1 , a motor control cabinet for a pumping unit provided by an embodiment of the present invention includes a glass fiber reinforced plastic box body 1, the box body 1 is divided into upper and lower layers, the upper layer is a weak current room 2, and the lower layer is a strong current room 3, and the inside of the box body 1 is vertically A glass fiber reinforced plastic partition 13 is directly arranged to divide the weak current room 2 and the strong current room 3 into two chambers; the front chamber of the weak current room 2 is provided with a remote control receiving module 10, a short message sending module 11 and a signal loop transformer 12; The front chamber of the chamber 3 is provided with a main power switch 4 , an alarm bell 5 , an AC contactor 6 , a control circuit switch 7 , a motor protector 8 and a capacitor switch 9 .

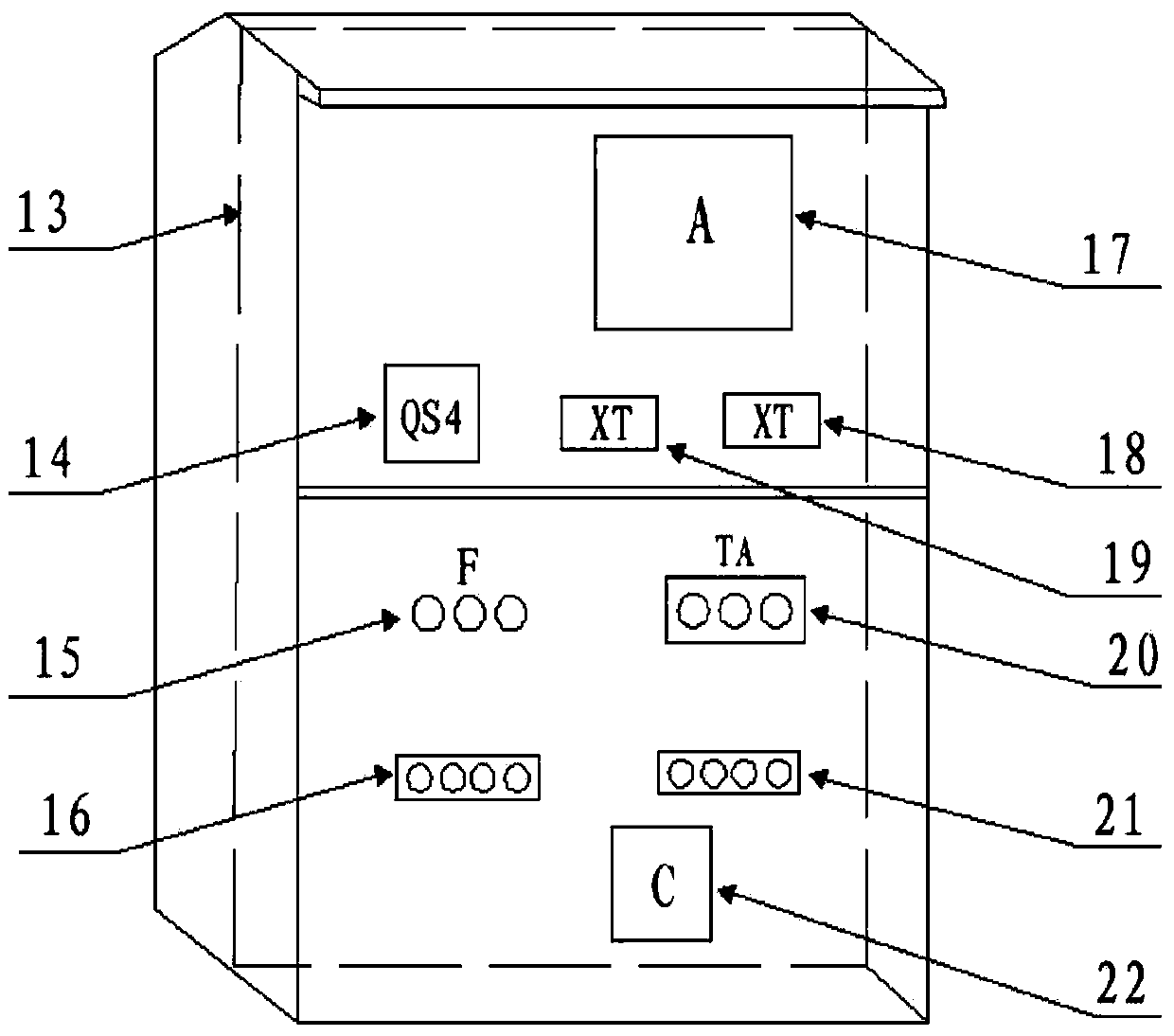

[0029] see figure 2 , the low-voltage remote transmission system control switch 14, single well signal acquisition de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com