Circuit board plugging system with pushing device with detachable vacuum sucker head

A circuit board plugging and vacuum suction cup technology, which is applied in the direction of assembling printed circuits, electrical components, electrical components, etc., can solve the waste of circuit board resources, the overall structure of the equipment is fragmented and complex, the degree of equipment integration and the adverse effects of structural design And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

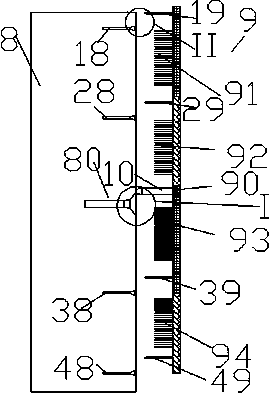

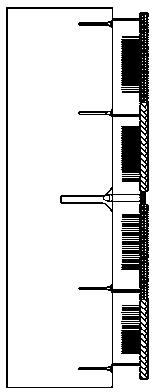

[0036] Combine below Figure 1-10 , the present invention is described in detail through the embodiments of specific examples.

[0037] A circuit board plug-in system with a detachable vacuum chuck head ejector device 5 is characterized in that it includes a circuit board device 9, a circuit board socket device 8 and the ejector device 5, and the ejector device is used for Pushing away described circuit board device 9 is inserted in the described circuit board socket device 8, and described pushing away device 5 comprises vacuum chuck head, pushing away arm 53 and vacuum supply pipe, and the end face of described vacuum chuck head is circular, A sealing ring 51 is attached thereto, and the sealing ring 51 is flexible and can maintain a seal while allowing the displacement of the vacuum chuck head relative to the bonding surface of the circuit board device 9, and the pushing arm 53 is Tubular, cooperate with the threaded protrusion on the side of the vacuum chuck head facing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com