Catalyst for manufacturing thermochemical fuel, and method for manufacturing thermochemical fuel

A manufacturing method and thermochemical technology, which can be used in catalyst activation/preparation, physical/chemical process catalysts, chemical elements of heterogeneous catalysts, etc., and can solve problems such as unresearched catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

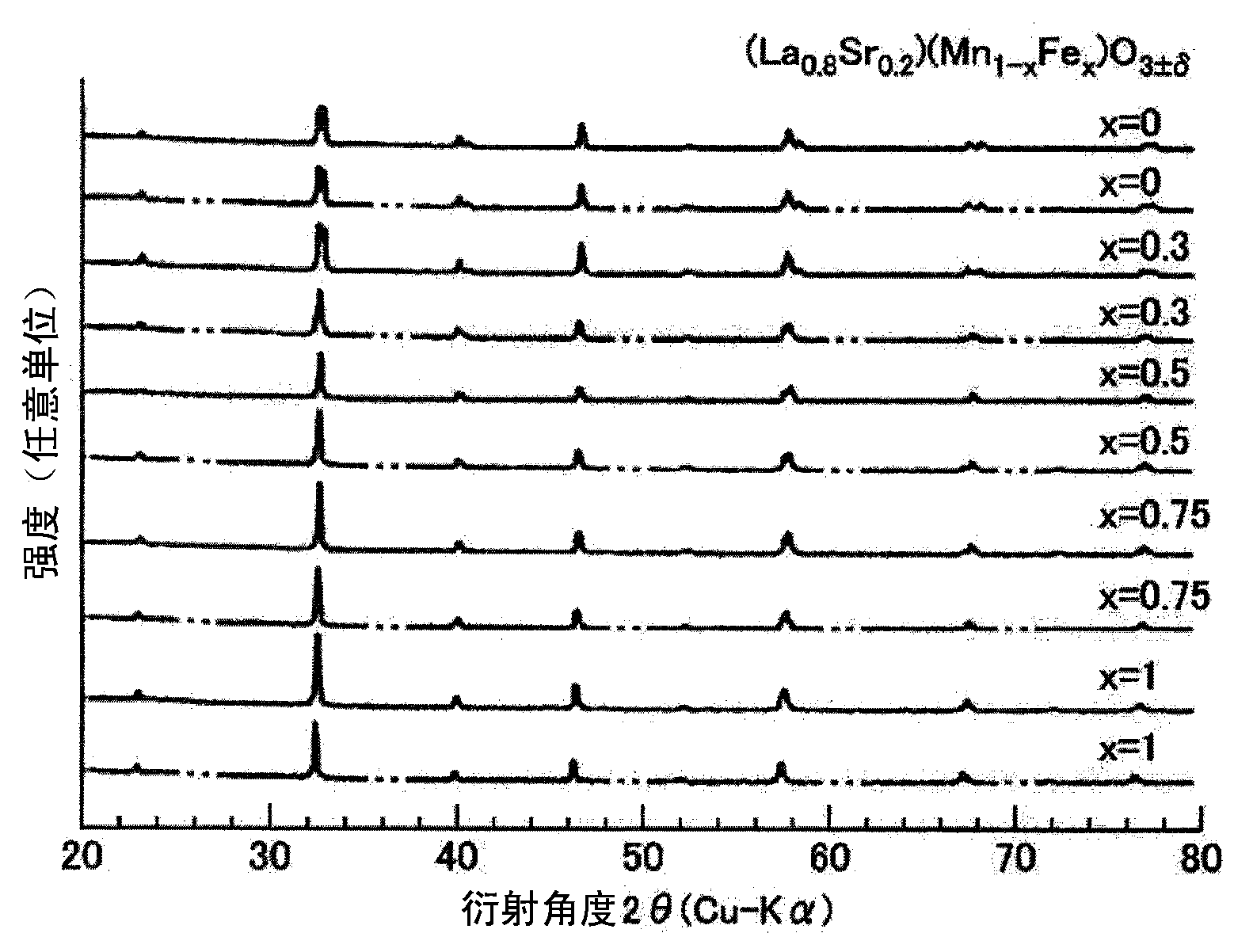

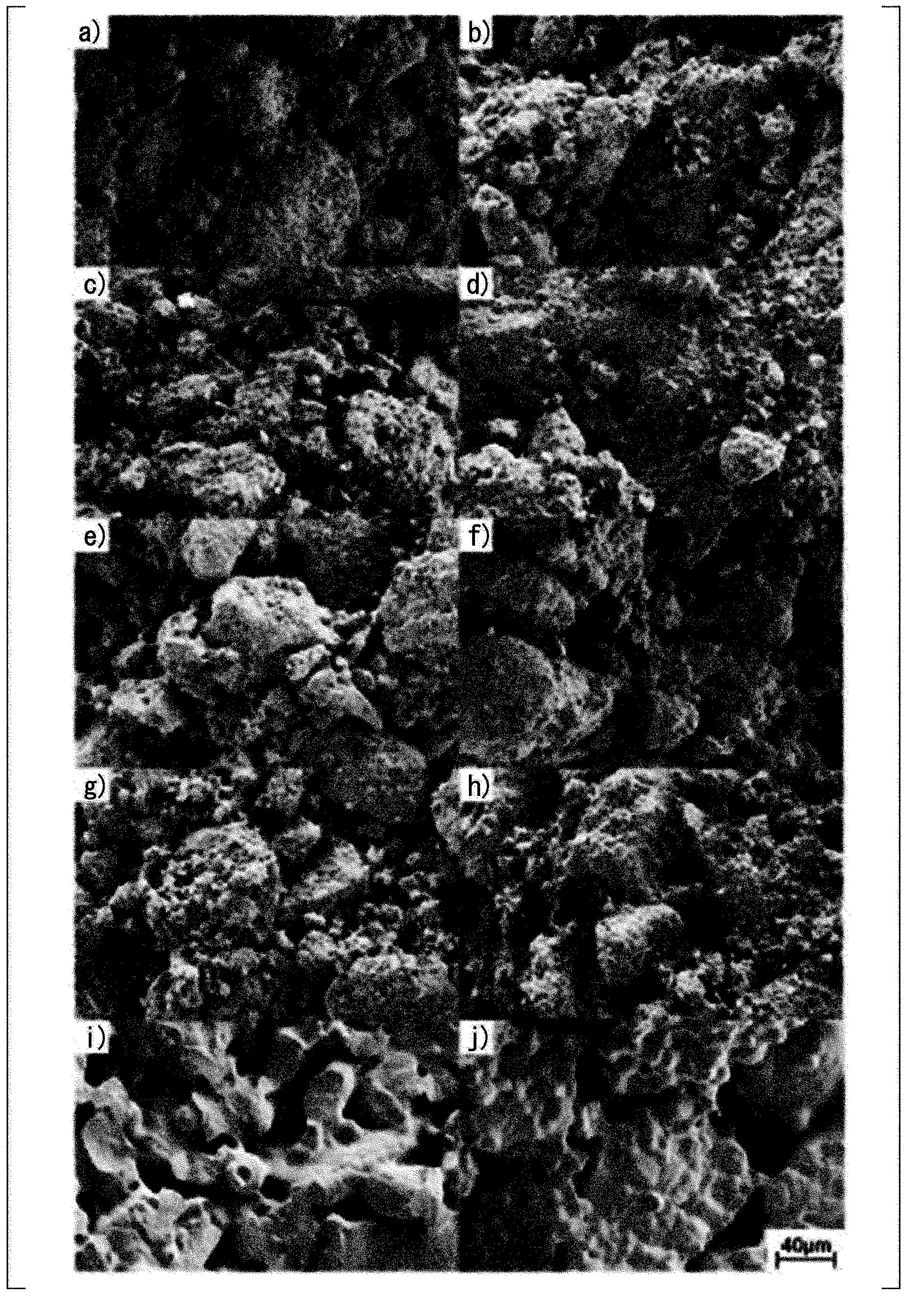

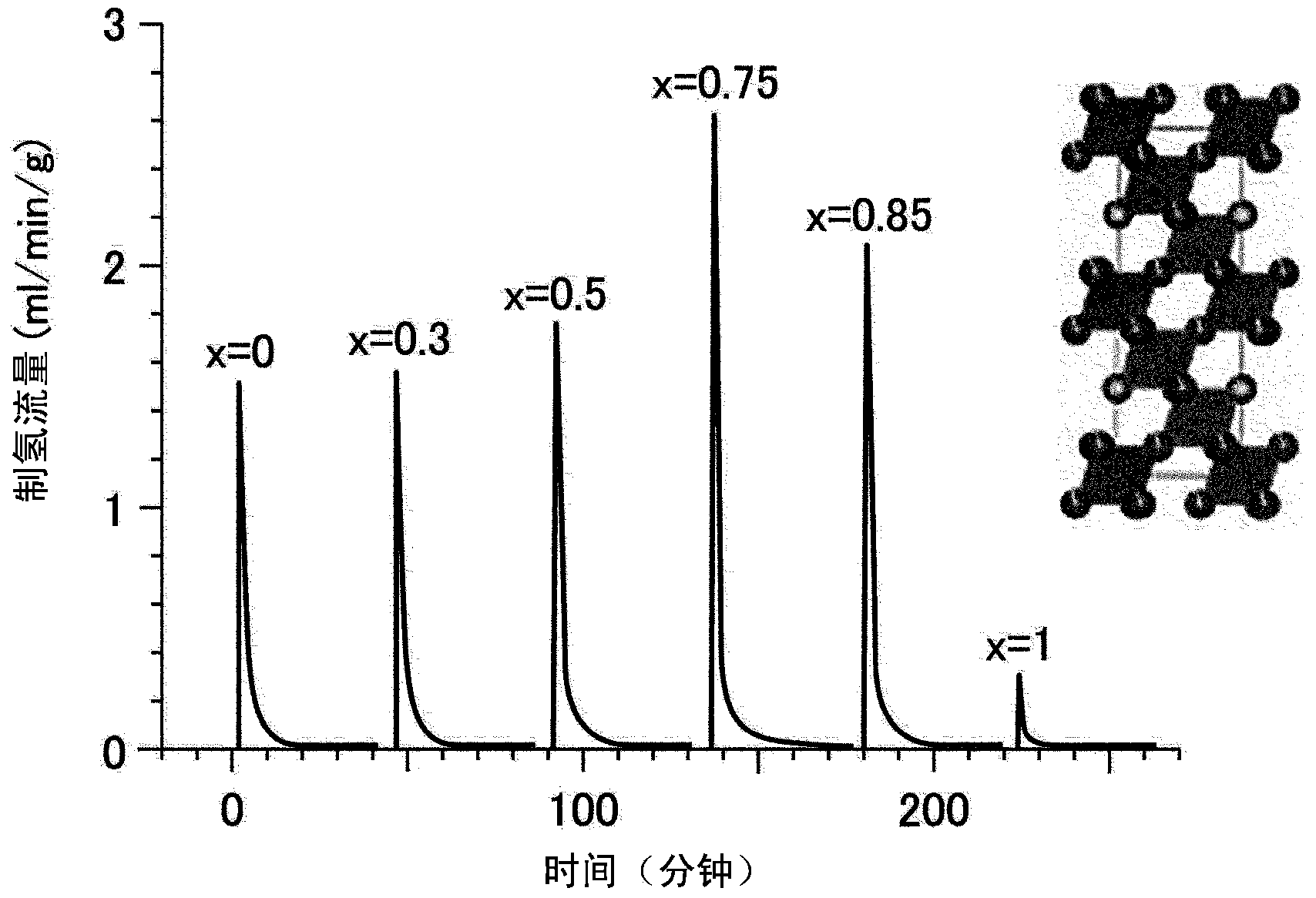

[0103] Hereinafter, the configuration of the catalyst for producing thermochemical fuel and the method for producing thermochemical fuel to which the present invention is applied will be described with reference to the drawings. In addition, in the drawings used in the following description, for the sake of easy understanding of features, characteristic parts may be enlarged and shown for convenience, and the dimensional ratio of each component may not necessarily be the same as the actual one. In addition, the Example shown in the following description is an example, and this invention is not limited to these, It can change suitably in the range which does not change the summary, and can implement.

[0104] The catalyst for thermochemical fuel production of the present invention is a thermochemical fuel production catalyst for producing fuel from thermal energy using a first temperature and a second temperature below the first temperature in a thermochemical cycle, and include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com