Method for reinforcing cutting edge of micro-cutting tool based on critical cutting thickness

A technology of cutting thickness and cutting edge, which is applied in the field of micro-tools, micro-tool edge strengthening based on critical cutting thickness, can solve the problems of inability to achieve segmented grinding, and achieve the goal of improving cutting conditions, facilitating implementation, and improving machining accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

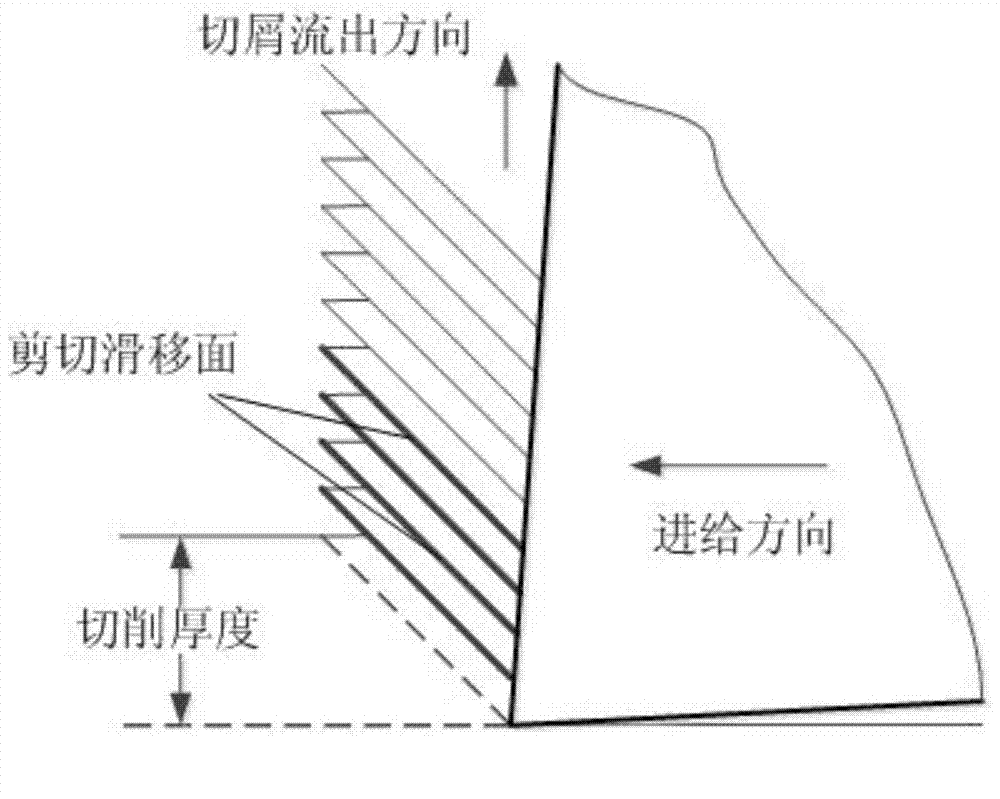

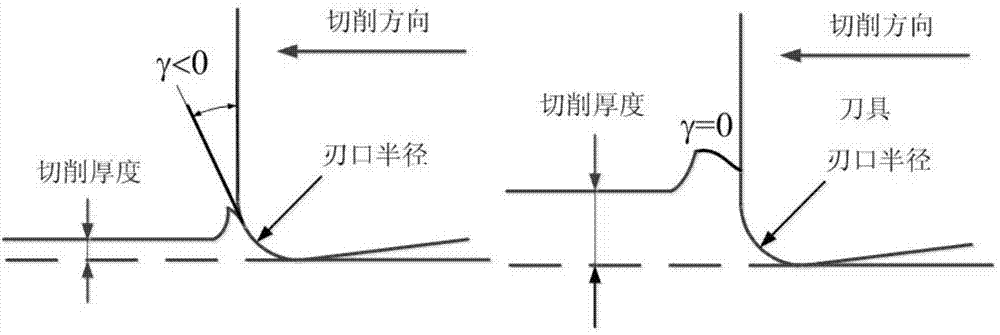

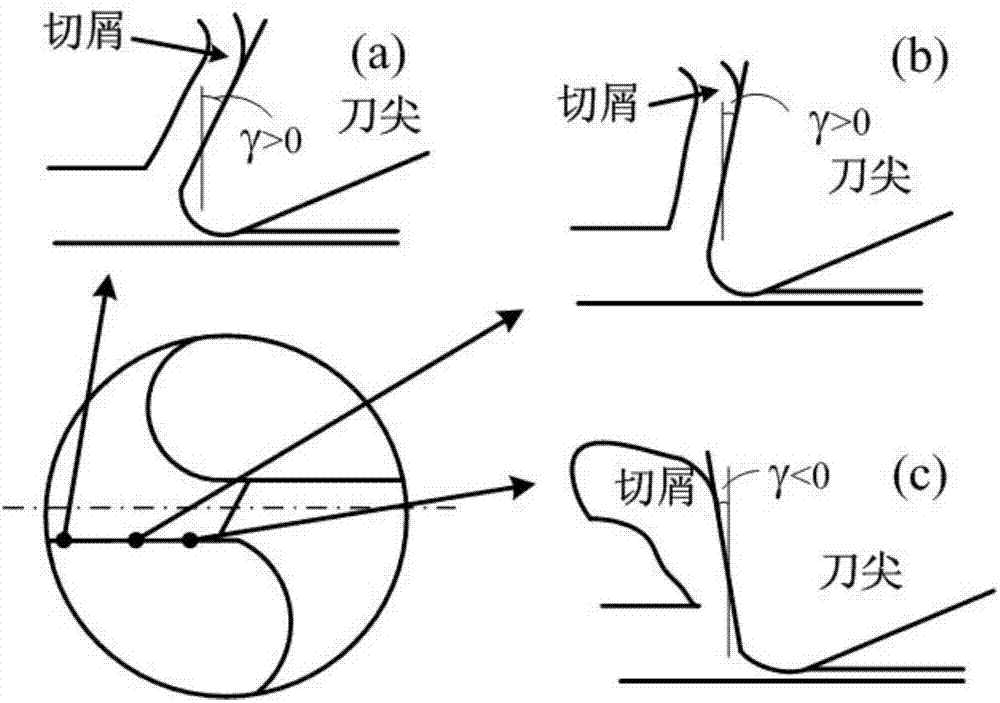

[0030] The invention relates to a cutting edge strengthening technology of a micro-knife, which can improve the cutting edge strength of the micro-knife, improve the cutting load distribution in the cutting edge area of the micro-knife, improve the cutting state, and improve the cutting performance; it mainly relies on changing the cutting edge The blunt circle radius distribution of the area, and the change is based on the critical cutting thickness of the processed material and the processing conditions of the tool edge area, so that the cutting edge of the main cutting edge of the tool can be cut in the most reasonable situation .

[0031] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. The following embodiments are based on the technical solutions of the present invention, providing detailed implementation and specific operating procedures, but the scope of protection of the present invention is not lim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com