Machining method of stainless steel part with aluminum honeycomb core

A technology of parts processing and aluminum honeycomb, which is applied in the field of mechanical parts processing and manufacturing, can solve the problems of inability to complete the CNC machining of stainless steel aluminum honeycomb sandwich parts, the honeycomb structure does not allow the use of liquid coolant, and the bonding strength of the honeycomb sandwich structure is affected. Achieve the effect of avoiding thermal melting, improving cutting conditions, reducing yaw and chatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

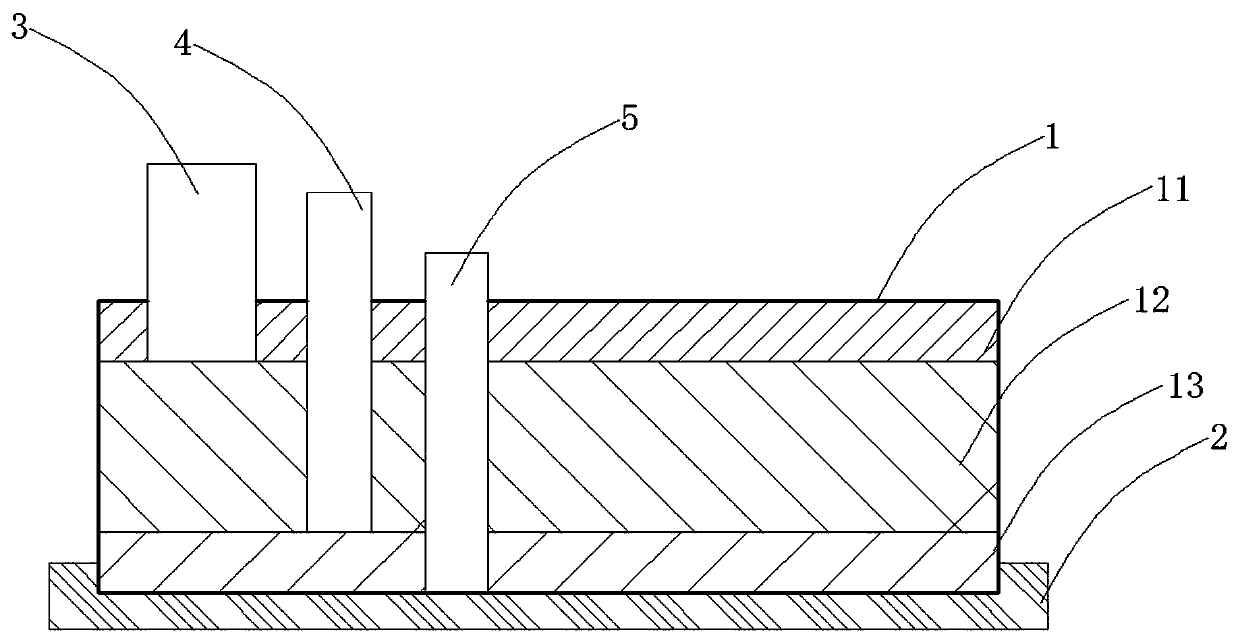

[0026] The main structure of this embodiment, such as figure 1 Shown, a kind of stainless steel aluminum honeycomb sandwich part processing method comprises the following steps:

[0027] (1) Install the part body on the machine tool table through the positioning fixture, make the lower surface of the part body fit the upper surface of the positioning fixture, and the plane where it is fitted is used as the clamping positioning surface;

[0028] (2) In the process of using CNC to process the part body, different milling cutters are used respectively based on the clamping positioning surface, and the milling process is carried out in layers for different materials in the part body in turn. All milling cutters are milled by trochoidal milling milling of the part body;

[0029] (3) After the milling of the part body is completed, remove the burrs after processing the part body, thereby completing the processing of the entire part body.

[0030] The specific implementation is tha...

Embodiment 2

[0033] On the basis of the above-mentioned embodiments, this embodiment further defines the structure of the part body 1, such as figure 1 As shown, the part body 1 is composed of the upper stainless steel layer 11, the middle aluminum honeycomb layer 12, and the lower aluminum plate layer 13. When the part body 1 is fixed on the machine tool workbench by the positioning fixture 2, the aluminum plate layer 11 in the part body 1 The lower surface of the lower surface is bonded with the upper surface of the positioning fixture 2, and the bonding surface is the clamping positioning surface. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

Embodiment 3

[0035] On the basis of the foregoing embodiments, this embodiment further limits the number of milling cutters, such as figure 1 As shown, the stainless steel layer 11 of the part body 1 is milled by the first milling cutter 3, the aluminum honeycomb layer 12 is milled by the second milling cutter 4, and the aluminum plate layer 13 is milled by the third milling cutter 5; the first milling The tool paths of the cutter 3, the second milling cutter 4, and the third milling cutter 5 are identical, and the diameter of the first milling cutter 3 is greater than the diameters of the second milling cutter 4 and the third milling cutter 5, and the diameter of the second milling cutter 4 is different. Less than the diameter of the third milling cutter 5. Obtain the cycloidal milling cutter track of the part processing position through software tools, select the processing tool of stainless steel material for processing, and in the process of processing the stainless steel plate layer, en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com