Technique for preparing machine holding carbide alloy rack type gear shaper cutter

A technique of hard alloy and manufacturing process, which is applied in the field of cutting tools to achieve the effect of accurate size, no vibration and smooth cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

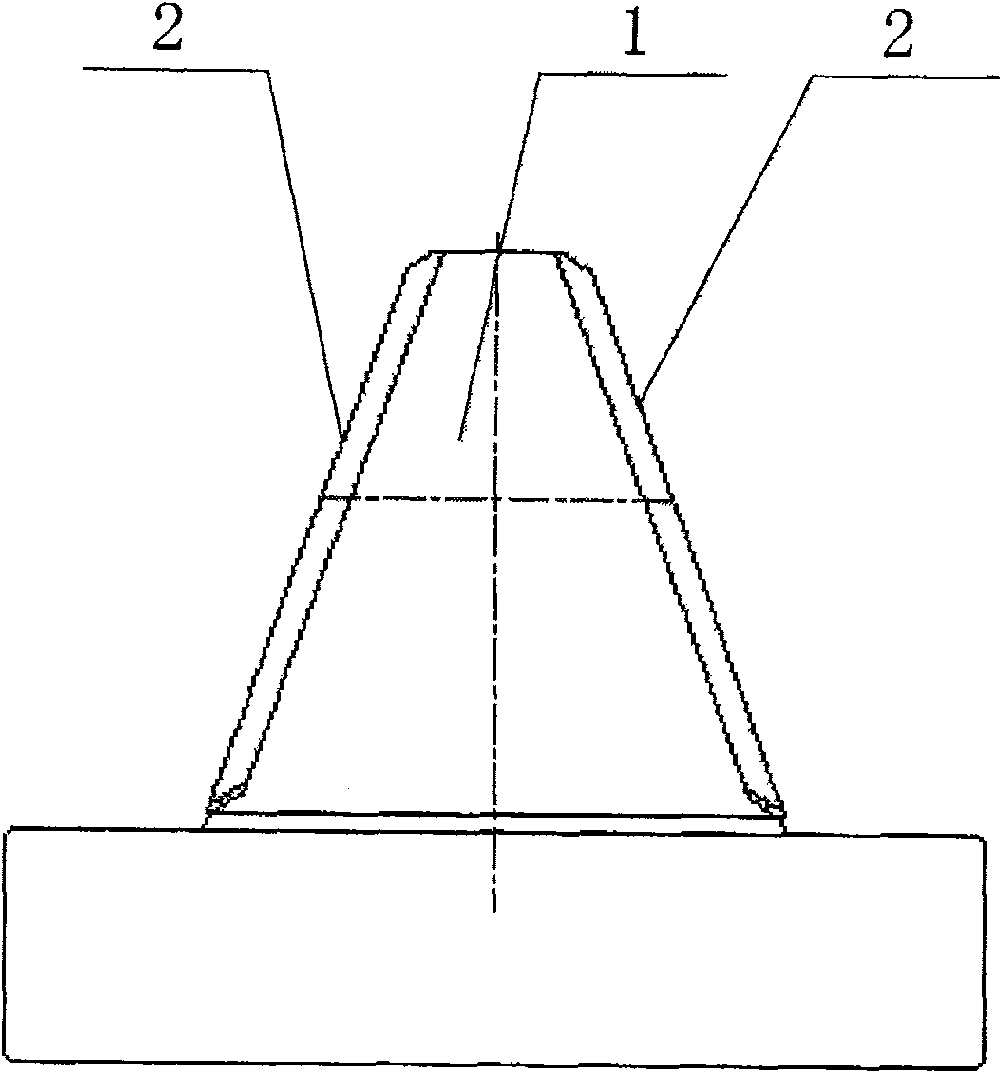

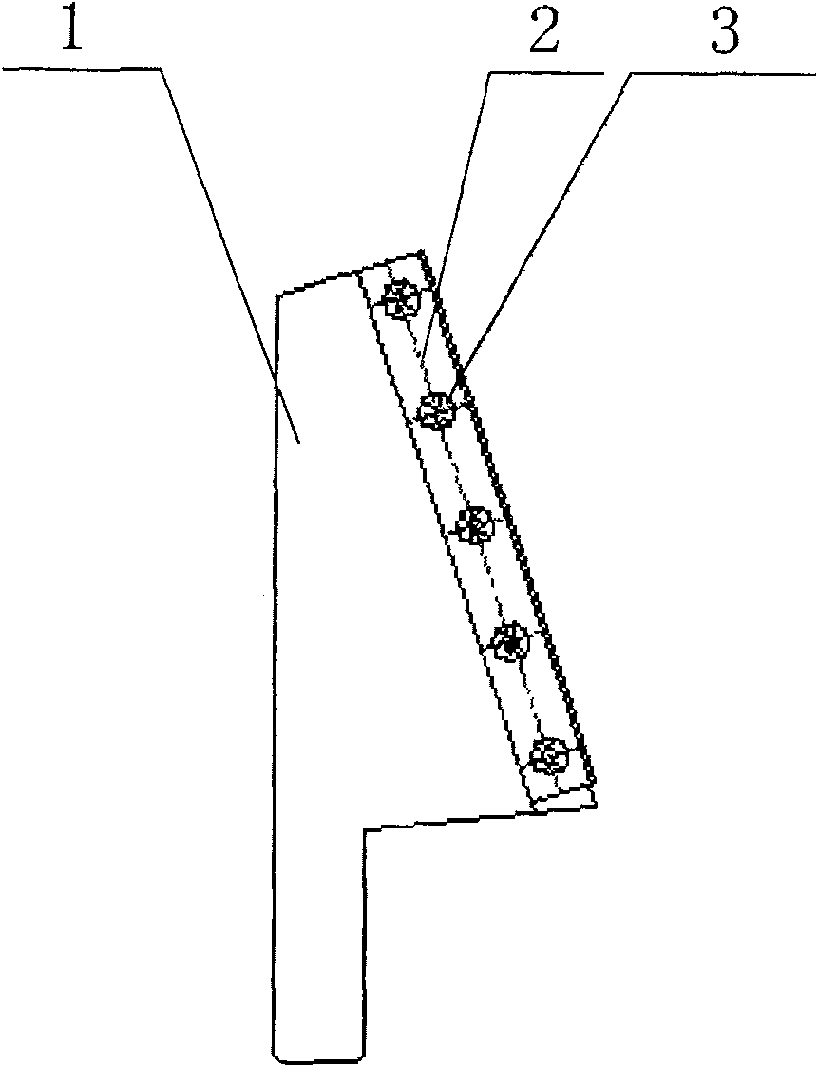

[0030] to combine figure 1 , 2 , the machine-clip cemented carbide comb-toothed cutter of the present invention is made up of blade 2 and cutter body 1 jointly, so its manufacturing process has also just included blade manufacturing process, cutter body manufacturing process and blade and cutter body assembly process. The blade is made of cemented carbide plate, the grade is YT798, and the threading hole of the positioning hole for assembly is pre-punched with an electric spark piercer, and then the thickness and width of the blade are ground by a special grinder to make it Meet the thickness size and roughness of the design requirements, then use slow wire cutting to cut the shape of the blade and the positioning hole for assembly, and evenly coat the blade with titanium aluminum nitride, use a special fixture to fine-mill the groove shape of the blade, and finally in the Coordinate boring out assembly positioning holes.

[0031] The cutter body is made of grade 42CrMo stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com