Hard alloy accurately-processed finger-type milling tool and process technique

A technology of cemented carbide blades and cemented carbides, which can be used in metal processing equipment, milling cutters, manufacturing tools, etc., and can solve problems such as inability to process hard tooth surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

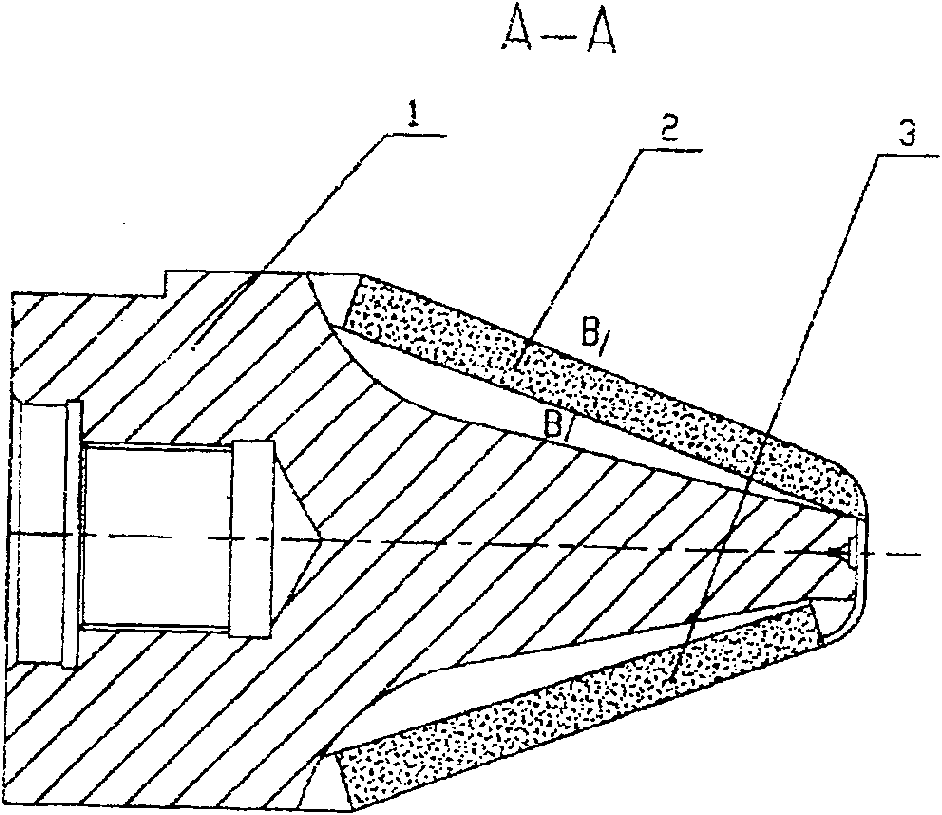

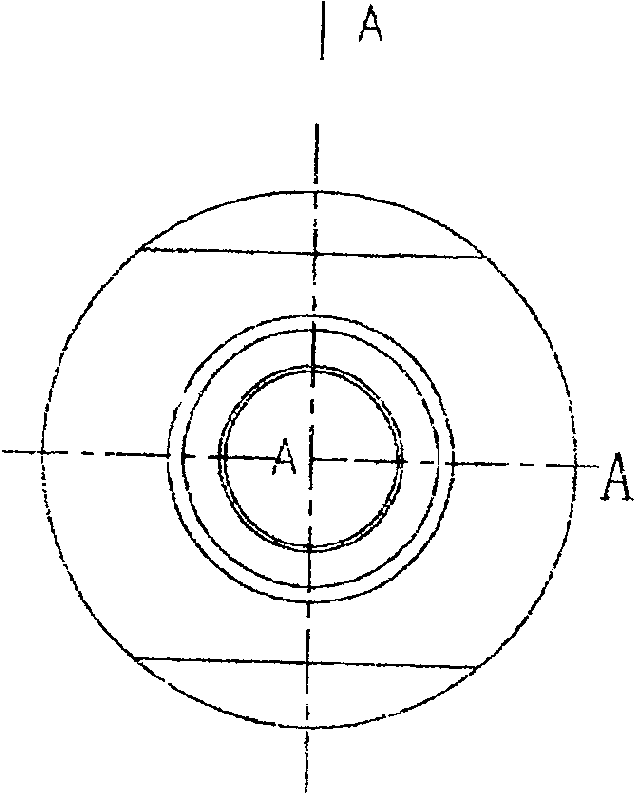

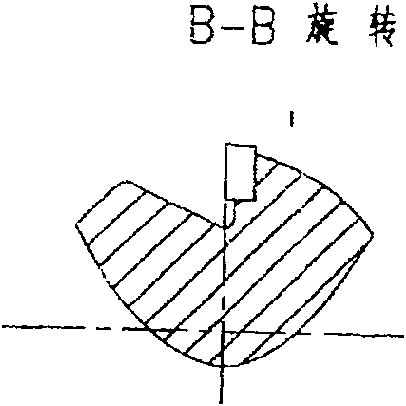

[0014] Such as figure 1 , 2 As shown in and 3: the tungsten carbide finishing finger milling cutter has a cutter body part, and a blade groove is milled on the cutter body, and the long blade and the short blade are welded on the cutter body; YG6X hard alloy plate is selected as the cutting edge For processing materials, 40Cr material is selected as the material of the cutter body. First, the shape of the cutter body and the chip groove are milled, and then a suitable blade groove is milled on the cutter body according to the blade blank. Before welding, the cutter body is preheated to 250°C , keep warm for 30 minutes; use high-frequency welding technology to weld the blade and the cutter body, and then grind out the positioning inner hole and end face, use the sharpening machine to cut the front edge, install the special tire tool to compile the tooth shape processing program based on the front edge surface, The tooth shape is cut out by high-precision slow-moving wire cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com