A kind of method that phosphotungstic acid modified metal-organic framework catalyzes the synthesis of bisphenol-F

A metal-organic framework, phosphotungstic acid technology, applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of small control range, complex process, difficult recycling of phosphoric acid catalysts, etc., to achieve no corrosion of equipment , Simple preparation process, easy separation and recovery and reusable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

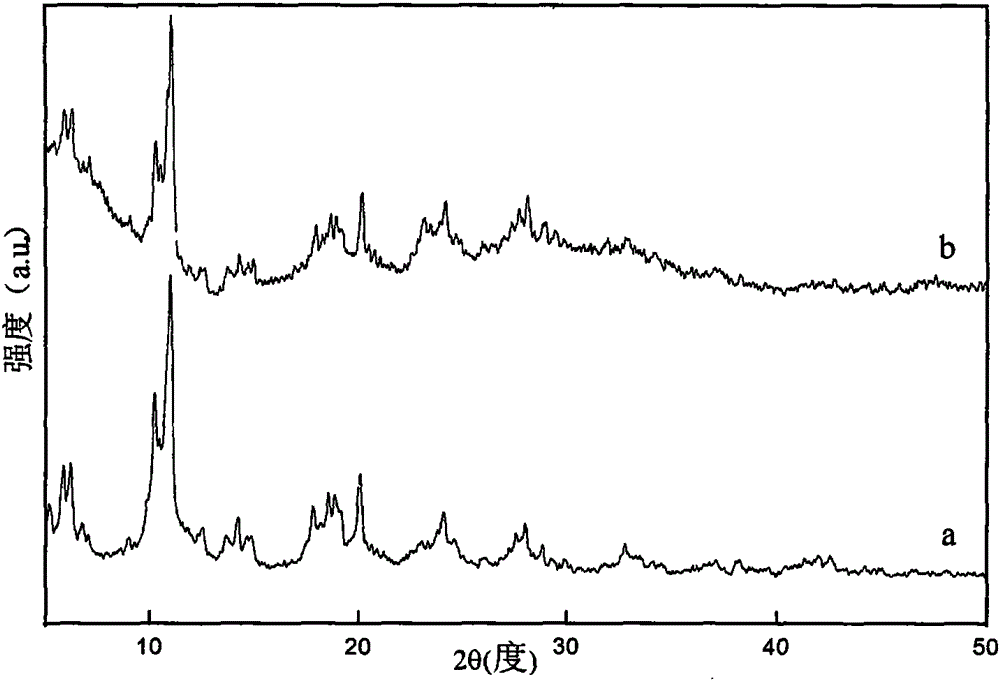

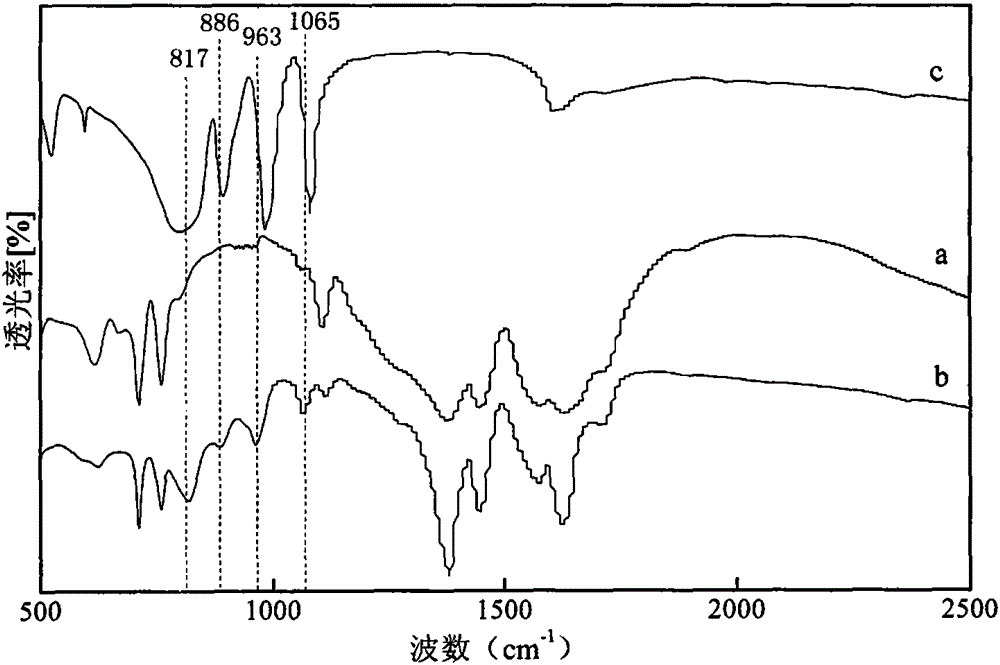

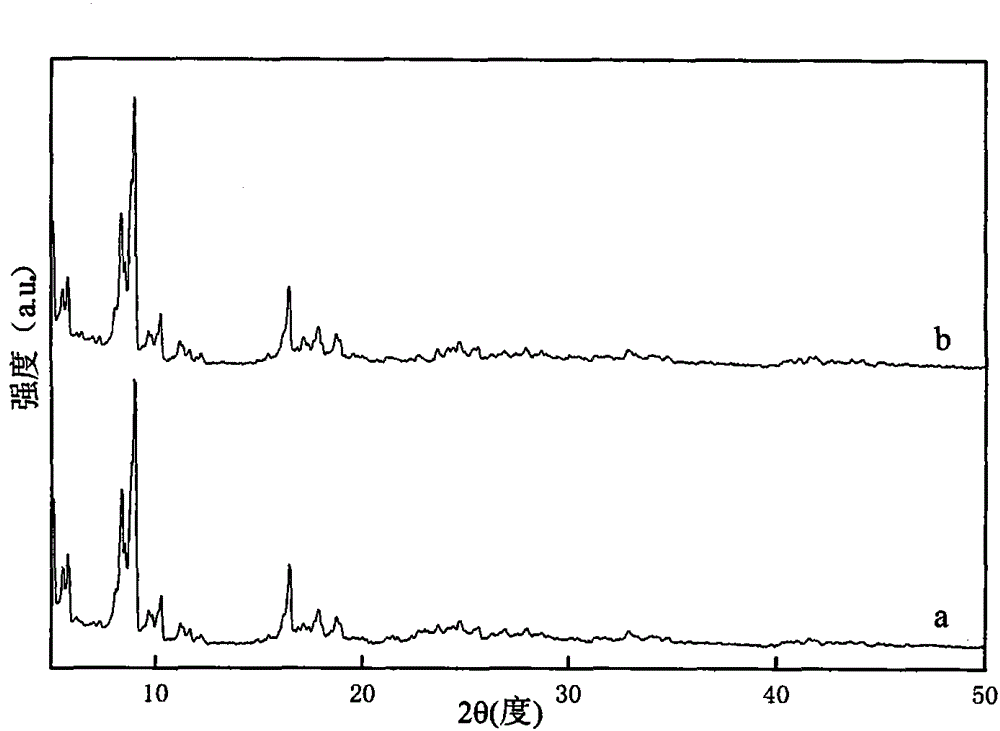

[0027] (1) Preparation of catalyst

[0028] Add 25.02g (1.39mol) of deionized water, 2.02g (5.00mmol) of ferric nitrate nonahydrate, 0.69g (0.24mol) of phosphotungstic acid, 0.71g (3.35mmol) of trimesin to a 100mL polytetrafluoroethylene liner Formic acid, stirred for 30min, heated from room temperature to 160°C, kept at 160°C for 12 hours, cooled, filtered, refluxed with 60°C 95% ethanol for 3 hours, refluxed with 70°C deionized water for 3 hours, and finally Dry at 150°C for 24 hours to obtain catalyst A.

[0029] (2) Synthesis of bisphenol F

[0030] Add 14.1g (0.15mol) of phenol and 0.3g of catalyst to a three-necked round-bottomed flask equipped with a condensing reflux tube, a thermometer and a magnetic stirrer, keep the temperature at 80°C, stir for 15min, and add 0.41g of formaldehyde aqueous solution with a mass percentage of 37% at one time (5mmol), reacted at 80°C for 4 hours, and the yield of bisphenol F was 89.26%. 33.70%, 15.11%, 51.19%.

Embodiment 2

[0032] The operation steps are the same as in Example 1, the difference is that the amount of phenol added during the synthesis of bisphenol F is 4.70 g (0.05 mol), and the yield of bisphenol F is 33.44%, wherein 2,4'-, 4,4'-, 2 , The mass percentages of the three isomers at the 2'-position are 50.36%, 18.56%, and 31.08%, respectively.

Embodiment 3

[0034] The operation steps are the same as in Example 1, the difference is that the amount of catalyst A added during the synthesis of bisphenol F is 0.03 g, and the yield of bisphenol F is 49.14%, wherein 2,4'-, 4,4'-, 2,2' The mass percentages of the three isomers at the -position are 48.19%, 19.81%, and 32.00%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com