Mortar spraying and smearing machine and method for painting mortar on wall surface by using mortar spraying and smearing machine

A mortar and flour technology, applied in the field of mortar sprayer and wall powder mortar, can solve the problems of difficulty in feeding materials, reduce construction efficiency, not conducive to energy saving, etc., and achieve the effects of good mobility and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

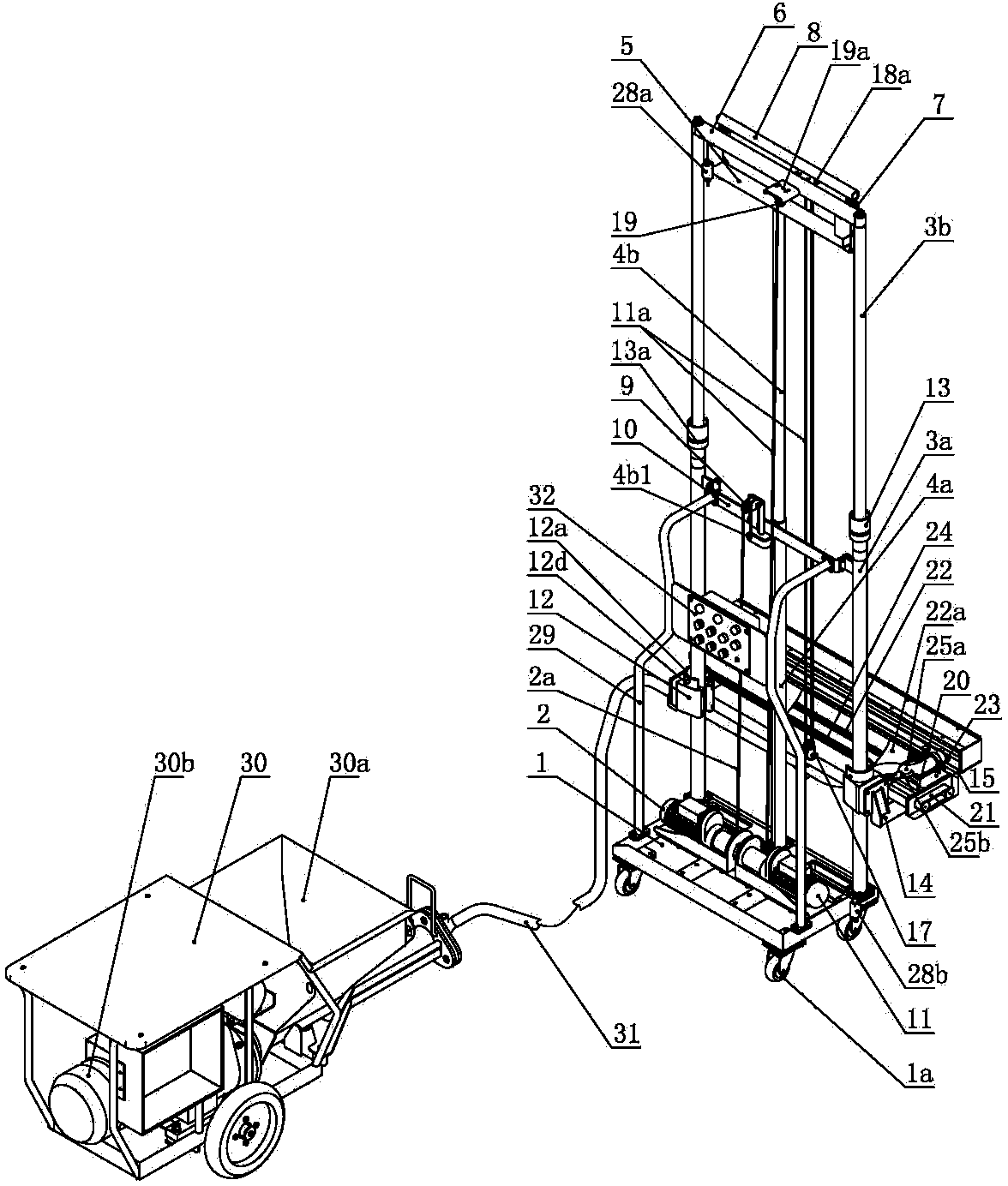

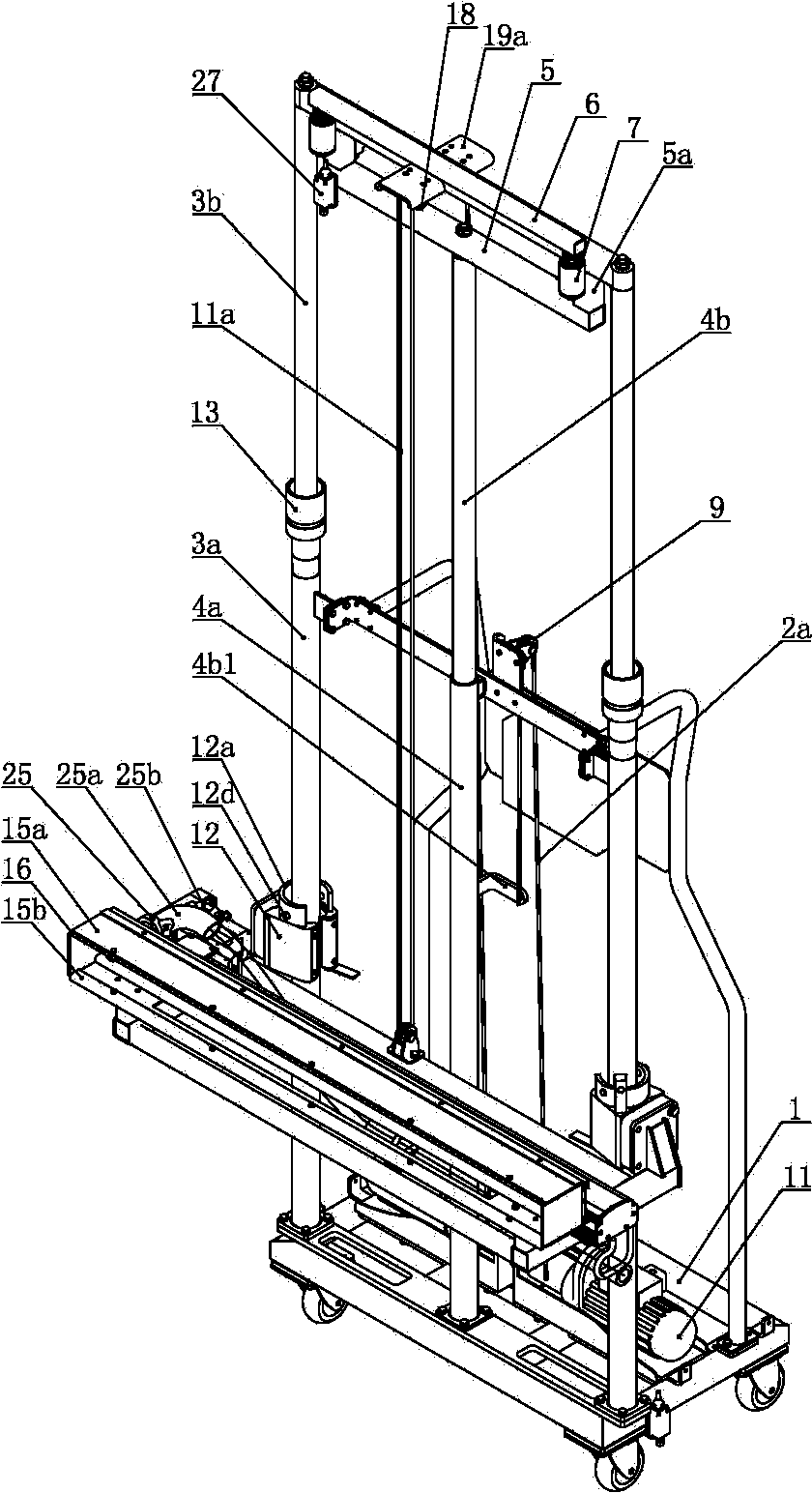

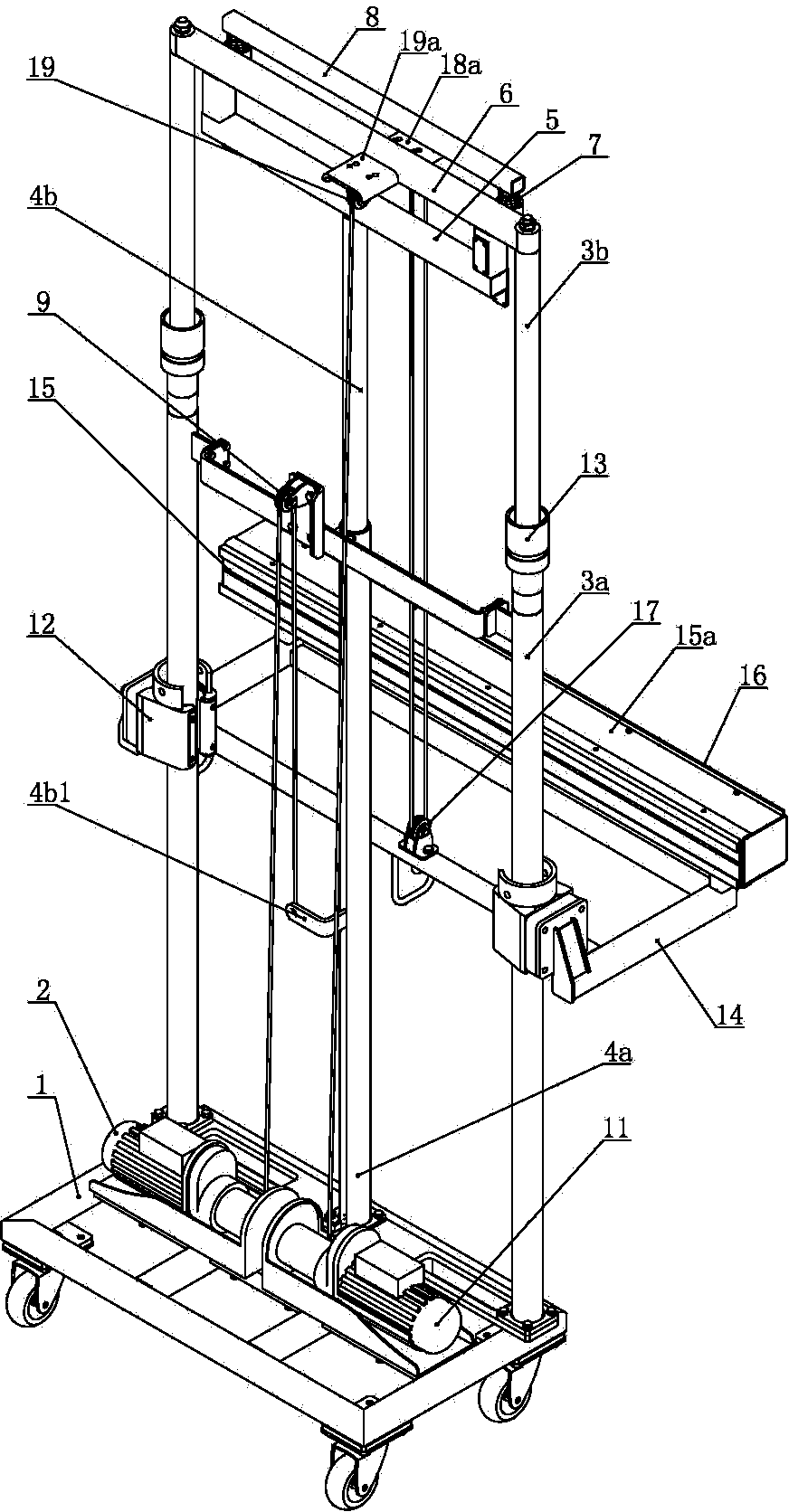

[0054] like Figure 1 to Figure 10 As shown, the mortar spraying machine of the present invention includes a mortar supply mechanism 30 and a spraying and leveling mechanism. The mortar supply mechanism 30 includes a mortar hopper 30a and a mortar pump 30b for loading mortar, the inlet of the mortar pump 30b is connected with the outlet of the mortar hopper 30a, the outlet of the mortar pump 30b is connected with the high-pressure mortar hose 31, and the spraying and leveling mechanism includes a base 1 , The bottom of base 1 is equipped with universal wheel 1a. The two corners of the front end of the base 1 are respectively connected with a vertically upward fixed lower door frame 3a, and the upper parts of the two fixed lower door frames 3a are connected to each other through a horizontal door frame 10. The lower door frames 3a are respectively plugged with sliding upper door frames 3b that can move along the fixed lower door frames 3a, and the tops of the two sliding upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com