Lining structure of a horseshoe-shaped shield tunnel

A shield tunnel and horseshoe-shaped technology, which is applied in the direction of tunnel lining, tunnel lining, shaft lining, etc., can solve the problems that circular tunnels cannot give full play to their structural advantages and low space utilization, so as to improve the stress conditions of bolts, reduce the number and Types, Effects of Optimized Geometry Design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

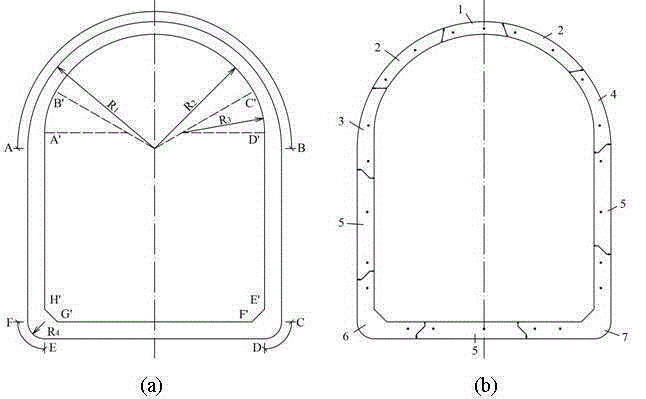

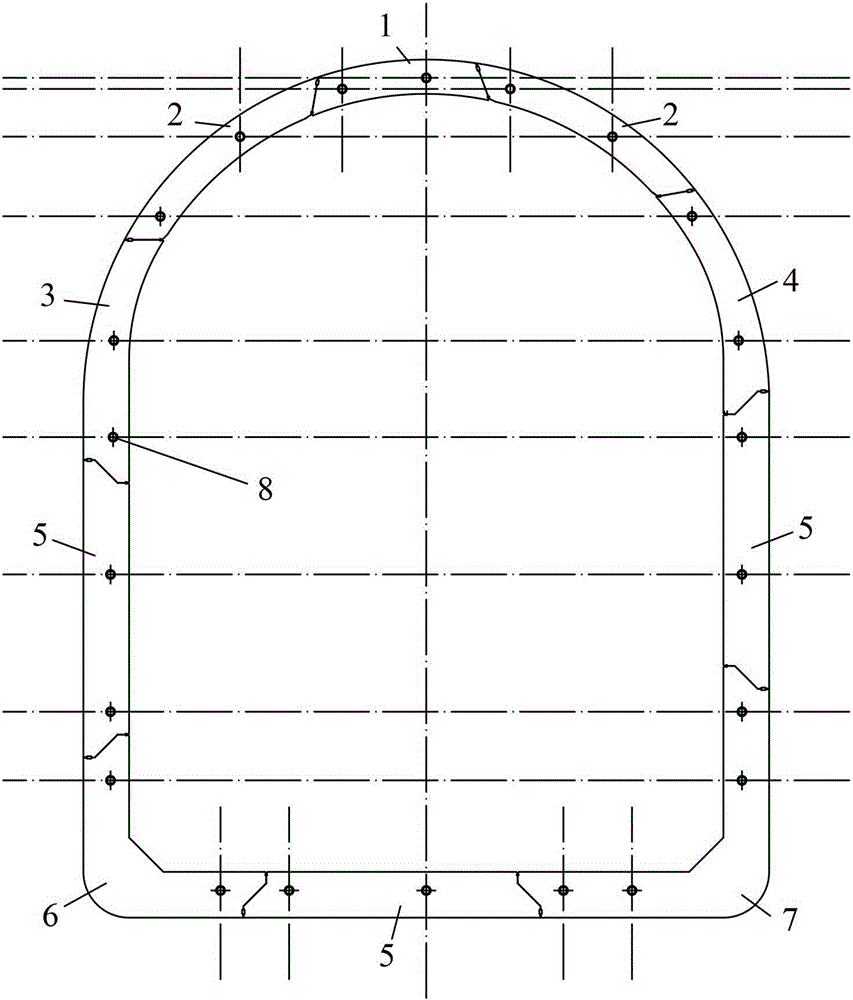

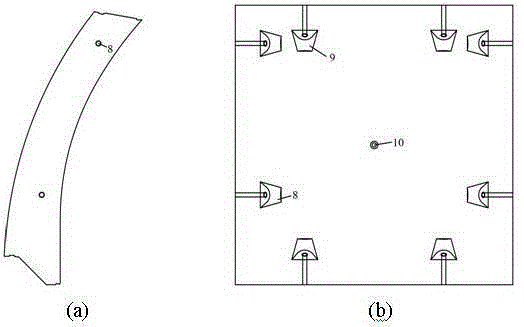

[0031] Embodiment 1: as Figure 1 to Figure 9 As shown, one ring of the horseshoe-shaped shield tunnel lining structure of the present invention includes 10 segments of 7 types, which are respectively a capping block 1, a first standard block 2, a first transition block 3, a second transition block 4, and a second standard block 5. The first corner block 6 and the second corner block 7 . There are longitudinal hand holes 8, circumferential hand holes 9 and grouting holes 10 on each segment. First assemble the second standard block 4 at the bottom, then assemble the first corner block 6 and the second corner block 7 to both sides, then assemble the second standard block 5 upwards, then assemble the first transition block 3 and the second transition block 4, and then Assemble the first standard block 2, and finally assemble the capping block 1. The top of the capping block 1, the first standard block 2 connected to its two sides and the first transition block 3 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com