High pressure DC swing check valve

A high-voltage direct current, swing-type technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve the problems of slow opening and closing of check valves, large disc reseating force, damaged pipelines, etc., to achieve opening and closing Fast speed, small recoil force, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

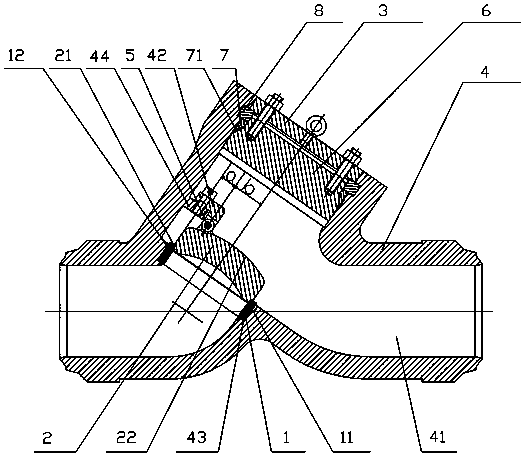

[0018] The embodiments of the present invention will be further described below in conjunction with the drawings:

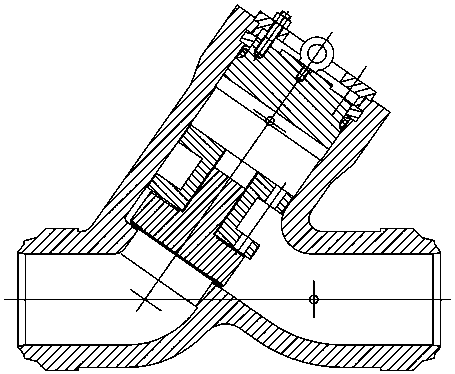

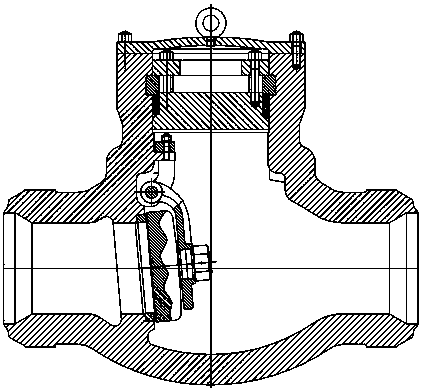

[0019] by image 3 As shown, a high-pressure direct current swing check valve includes a valve seat 1, a valve disc 2, a valve cover 3, and an integrated valve body 4. The valve body 4 is provided with a Y-shaped medium channel 41, so The inner wall of the valve body 4 is provided with a lug 44, the lug 44 is fixed with a cantilever, the cantilever 42 and the valve flap 2 are hinged by a hinge shaft 5. Specifically, the cantilever 42 and the valve flap 5 The 5-phase hinge is directly connected by the hinge shaft, avoiding the connection through the rocker arm, which shortens the opening and closing stroke and greatly reduces the valve opening and closing time. The hinge shaft 5 is arranged between the end surface of the valve flap 5 and the center line of the valve flap 5. Specifically, the distance from the hinge shaft 5 to the end surface of the valve disc 2 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com