Self-aligning universal bearing

A universal bearing, self-aligning technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., to achieve the effect of simple installation, improved component life, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

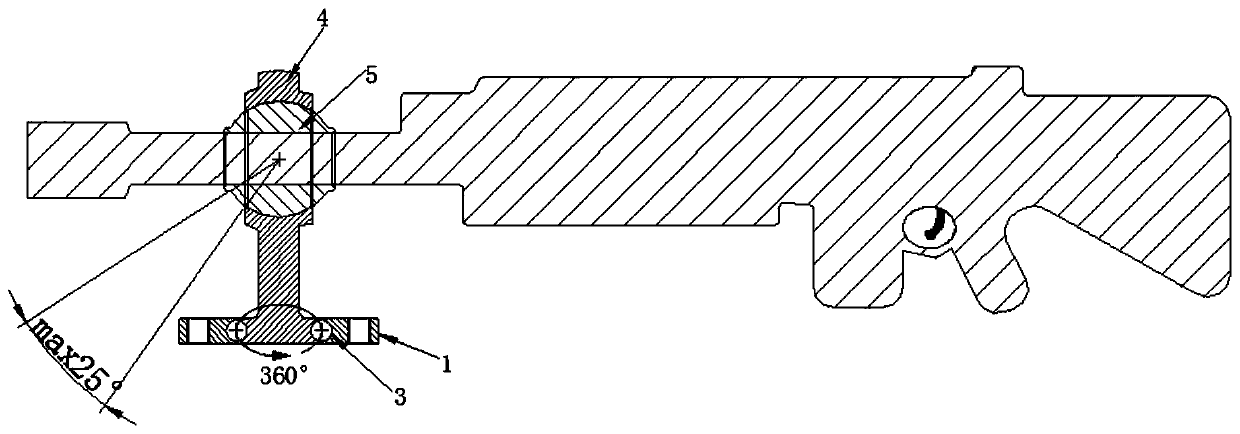

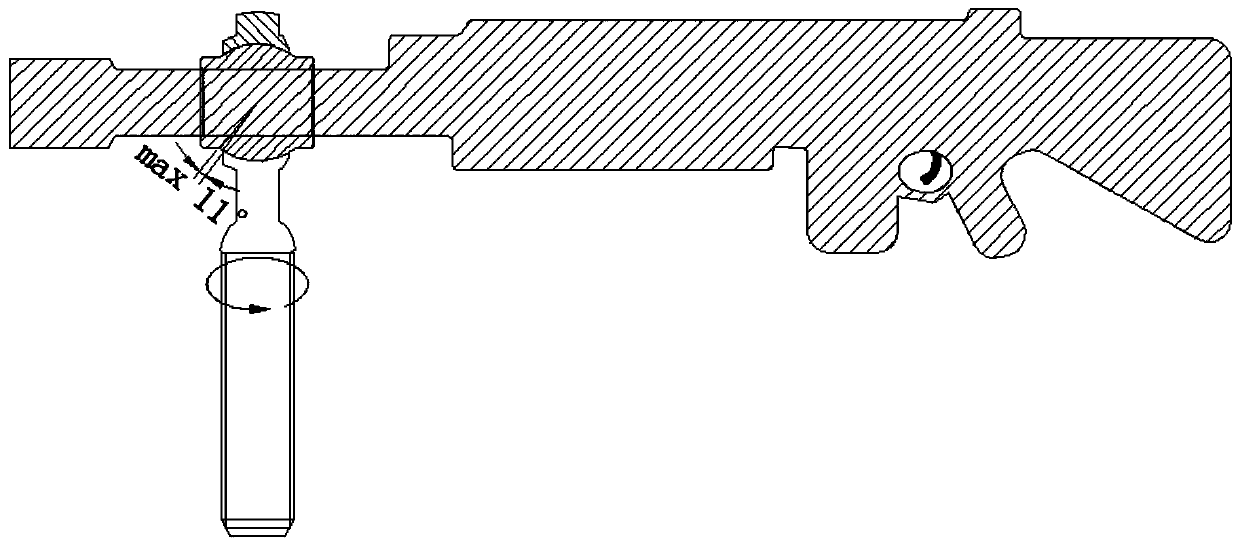

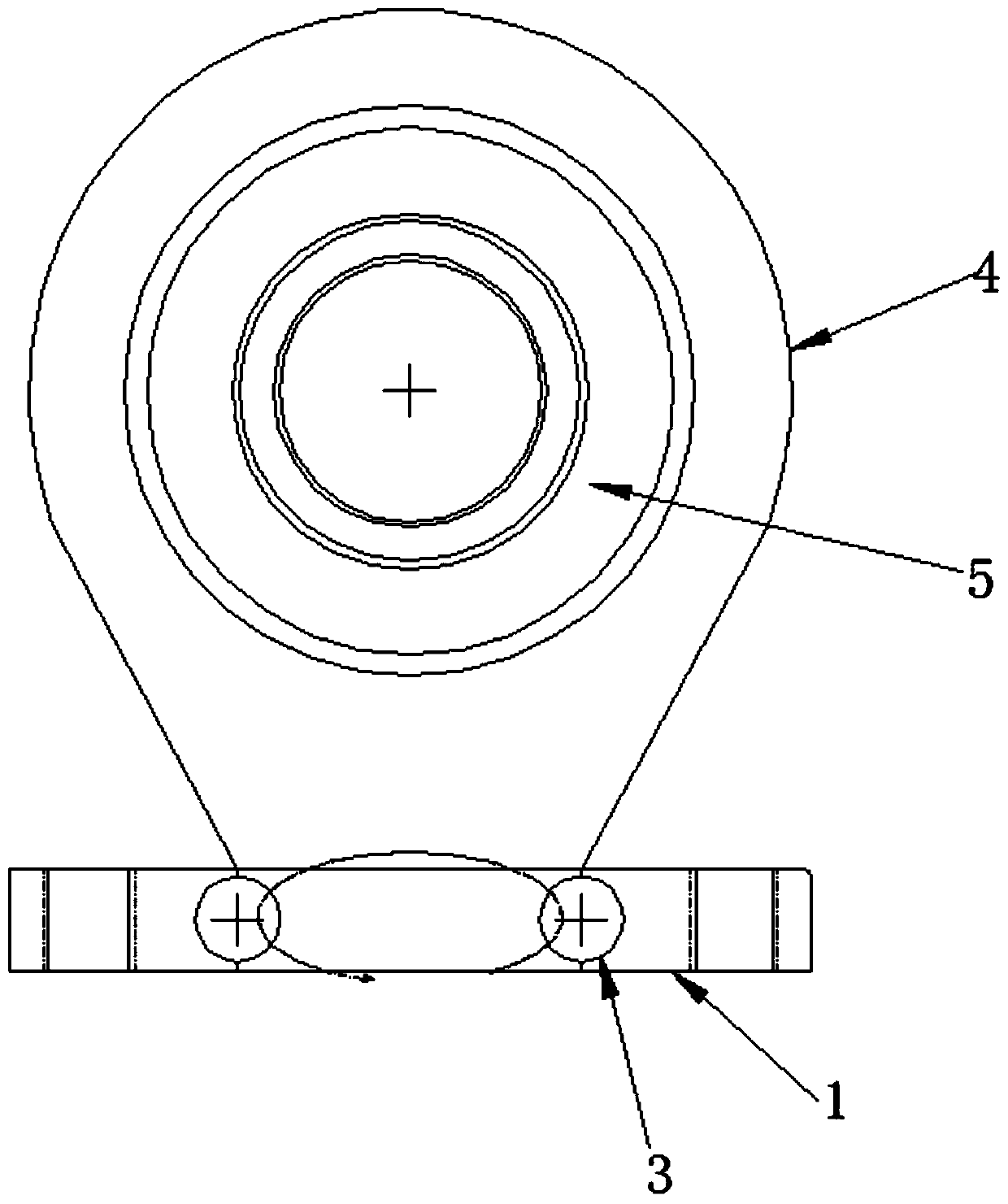

[0026] Embodiment 1, a self-aligning universal bearing according to the embodiment of the present invention includes a seat body 1, a circular groove is arranged in the seat body 1, a disc 2 is arranged in the circular groove, and the A number of steel balls 3 are inlaid between the side of the disc 2 and the inner wall of the circular groove, and the top of the disc 2 is provided with a rod end body 4, wherein the rod end body 4 runs through the seat The body 1 extends above the seat body 1, and the upper part of the rod end body 4 is provided with a hollow through hole, and a movable perforated ball 5 is arranged in the through hole, and the perforated ball 5 is connected with the rod A self-lubricating component 6 is embedded between the end bodies 4 .

[0027] The specific setting and function of the lower rod end body 4, the steel ball 3, the self-lubricating material and the seat body 1 are specifically described below.

[0028] 1. The rod end body 4 is made of special ...

Embodiment 2

[0032] Embodiment 2, the self-lubricating component 6 is composed of Kevlar fiber and PTFE fiber.

Embodiment 3

[0033] Embodiment 3, the firearm penetrates the perforated ball 5 , and the rotation angle of the firearm in the perforated ball 5 is 0-25 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com