A 3D printed silencer

A muffler device and 3D printing technology, applied in the manufacture of auxiliary devices, instruments, sound-producing instruments, etc., can solve the problems of increased recoil, difficult to clean, and a large number of components, and achieve the effect of reducing the recoil and improving the muffler effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

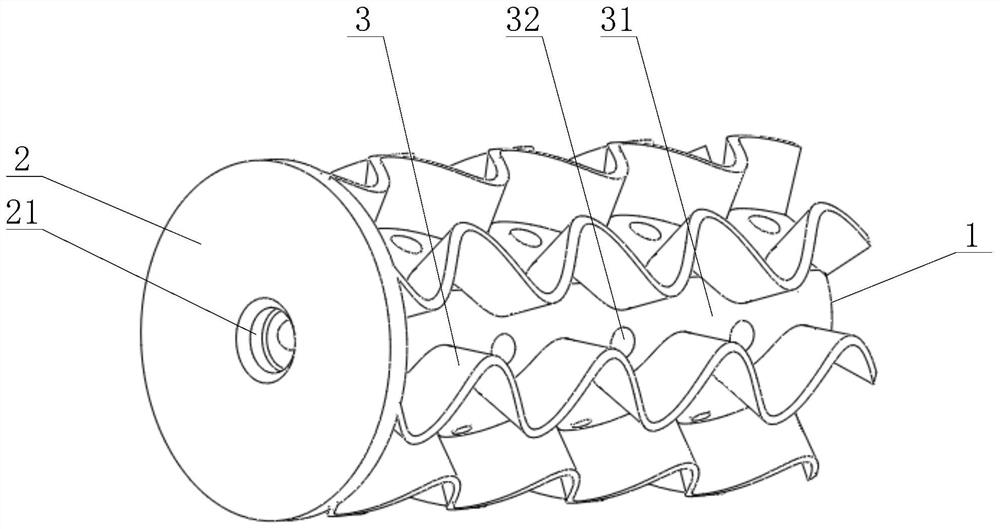

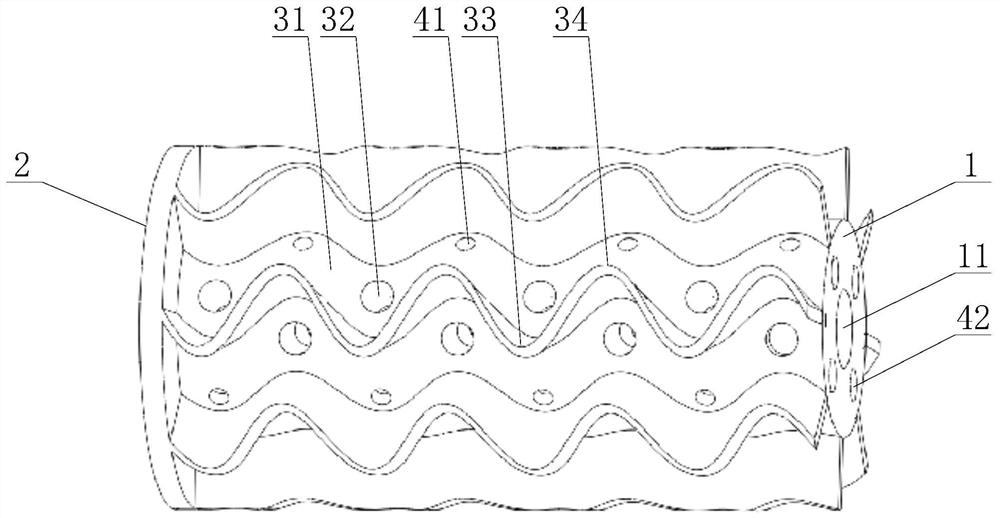

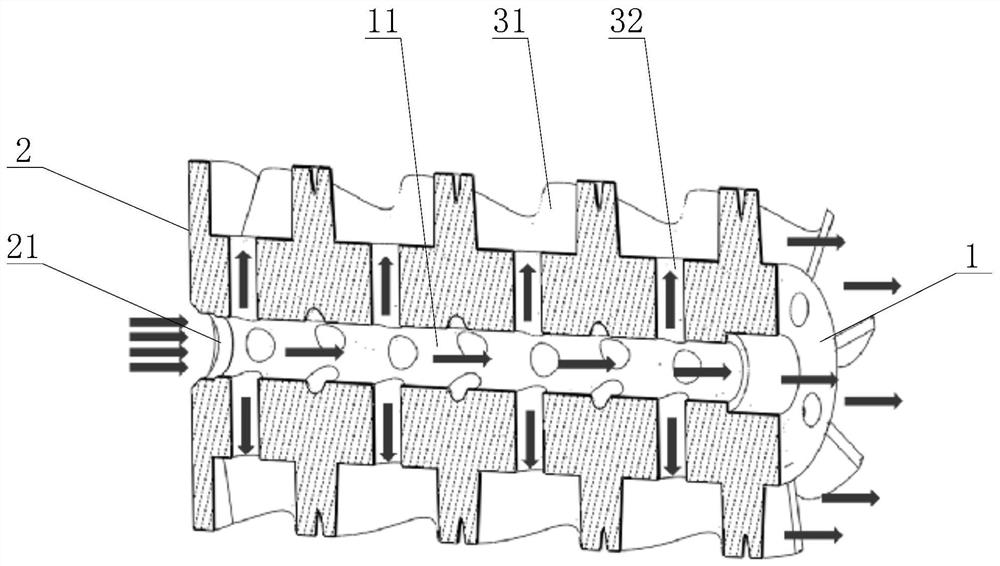

[0024] Example: as attached Figure 1-7 As shown, the present invention is a 3D-printed muffler device, comprising a cylindrical muffler body 1 , a main air passage 11 extending through the muffler body 1 along the axial direction of the muffler body 1 is provided in the middle of the muffler body 1 .

[0025] One end of the muffler body 1 is provided with an air intake end face 2 , and an integrated structure is adopted between the intake end face 2 and the muffler body 1 , and an air inlet 21 communicated with the main air passage 11 is provided in the middle of the air intake end face 2 , the outer diameter of the intake end face 2 is larger than the outer diameter of the muffler body 1 .

[0026] The outer wall of the muffler body 1 is centered on the axis line of the muffler body 1, and the annular array is provided with a plurality of curved expansion chamber airway walls 3, two adjacent curved surface expansion chamber airway walls 3, the air inlet end face 2 and the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com