Automatic defrosting system for medical refrigerators

A refrigerator, automatic technology, applied in defrosting, household refrigeration devices, applications, etc., can solve the problems of deviating from the refrigeration target temperature and failing to achieve the effect of defrosting, and achieve the effect of improving preservation quality and maintaining temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

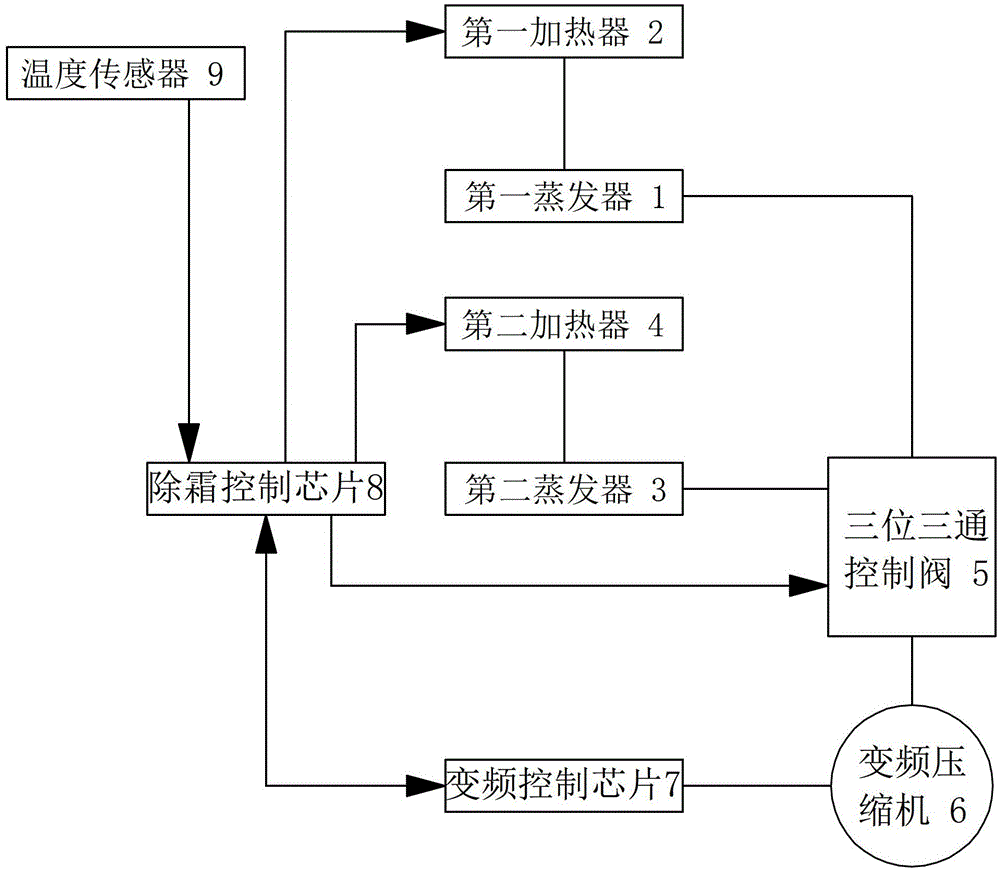

[0022] See figure 1 , the automatic defrosting system of the medical refrigerator of this embodiment includes a first evaporator 1, a first heater 2 arranged on the first evaporator 1, a second evaporator 3, and a second evaporator 3 arranged on the second evaporator 3. The second heater 4, the three-position three-way control valve 5, the frequency conversion compressor 6, the frequency conversion control chip 7 for controlling the working frequency of the frequency conversion compressor, the temperature sensor 9 for real-time detection of the temperature in the box and the control start Defrost control chip 8 for defrosting and ending defrosting. The signal end of the temperature sensor 9 is connected with the signal end of the defrosting control chip 8 . The signal terminals of the defrosting control chip 8 are respectively connected with the control terminals of the first heater 2 , the second heater 4 and the three-position three-way control valve 5 , and the signal term...

Embodiment 2)

[0032] The rest of this embodiment is the same as Embodiment 1, the difference is: the first operating frequency f of the compressor in this embodiment 1 25Hz, T 1 is 3.2°C, so the second operating frequency of the compressor is f 2 is 41.6Hz.

Embodiment 3)

[0034] The rest of this embodiment is the same as Embodiment 1, the difference is: the first operating frequency f of the compressor in this embodiment 1 25Hz, T 1 is 3.8°C, so the second operating frequency of the compressor is f 2 is 46.4Hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com