Gas input control method and system for use in manufacture of semiconductor devices

A technology for equipment manufacturing and gas control, which is applied in the direction of flow control using electrical devices, and can solve problems such as low efficiency of gas path setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

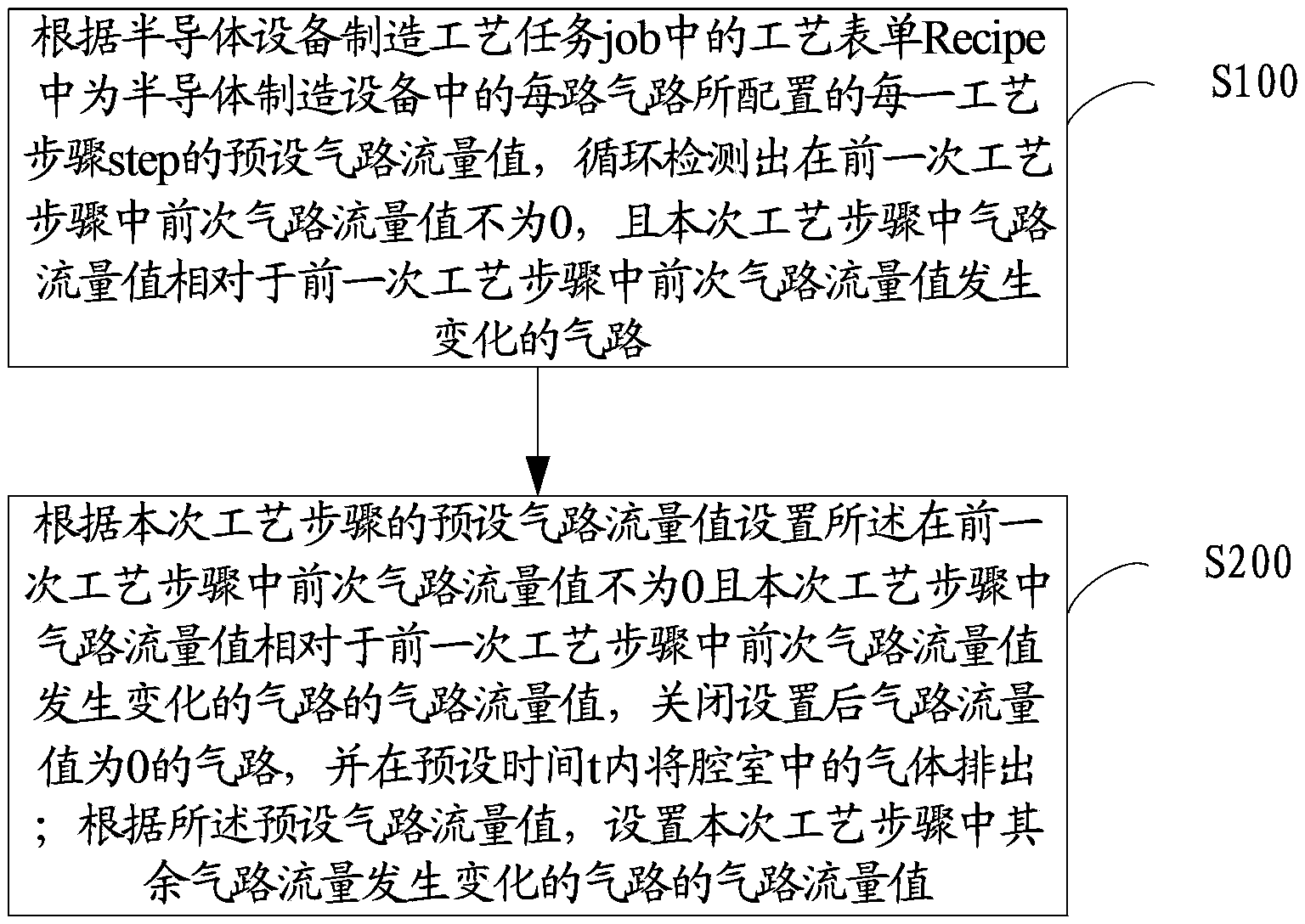

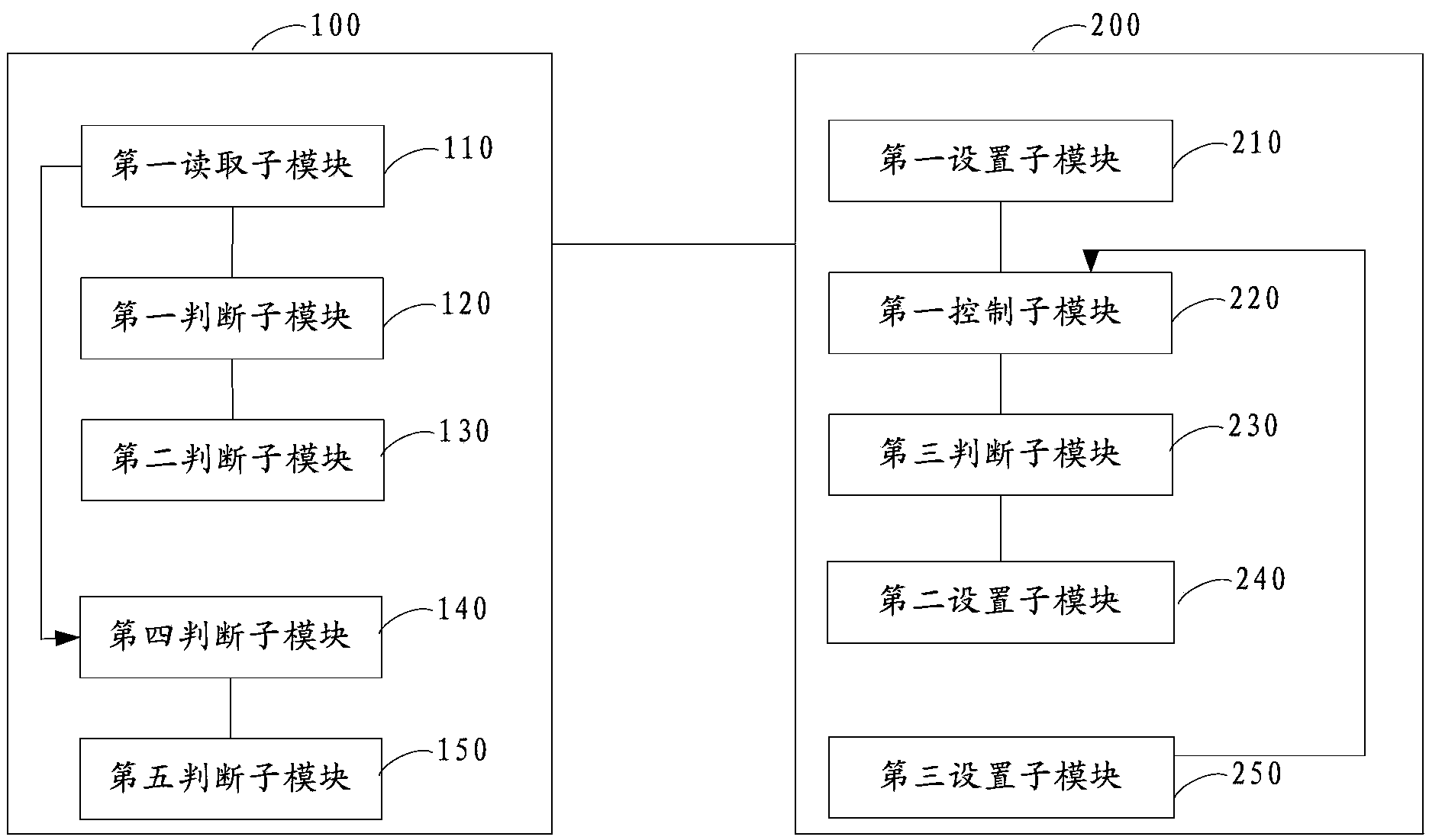

[0076] Preferably, as an implementable manner, the S100 includes the following steps:

[0077] S110, in this process step, from the process list in the semiconductor equipment manufacturing process task, read the preset gas path flow value configured for each gas path in the semiconductor manufacturing equipment in this process step, and Acquiring the flow rate value of the previous gas path of the previous process step of the current process step of the gas path;

[0078] What needs to be explained here is that the initial value of the gas path flow value of the current process step of each gas path and the previous gas path flow value of the previous process step of the current process step is 0.

[0079] S120, judging whether the preset gas path flow rate value in this process step of each gas path is greater than or equal to 0.1; if not, execute step S130; if yes, directly return to step S110 until each gas path is cycled;

[0080] What needs to be explained here is that ...

Embodiment 2

[0100] Preferably, as another implementable manner, the S100 includes the following steps:

[0101] S110', in this process step, from the process table in the semiconductor equipment manufacturing process task, cyclically read the preset gas path flow value configured for each gas path in the semiconductor manufacturing equipment in this process step, And obtain the previous gas path flow rate value of the previous process step of the current process step of the gas path;

[0102] S120', judging whether the previous gas path flow value of each gas path is greater than or equal to 0.1; if yes, then execute step S130'; otherwise, directly return to step S110' until each gas path is cycled;

[0103] What needs to be explained here is that the judging whether the previous gas path flow value of each gas path is greater than or equal to 0.1, that is, judging whether the gas path flow value of the previous process step of the gas path is 0, the previous gas path flow value of the ga...

example 1

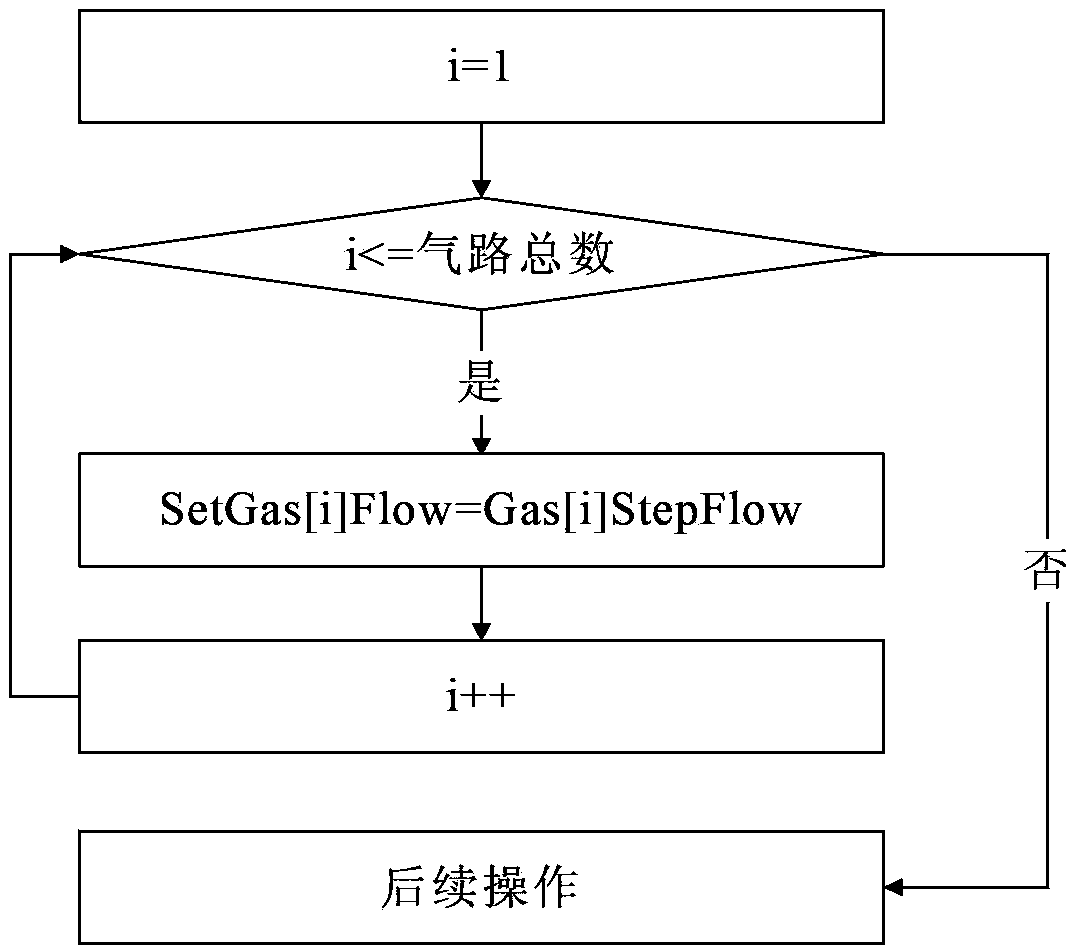

[0142] Such as Figure 4 As shown, the specific implementation flow chart of Example 1.

[0143] In order to set the gas path flow, first initialize:

[0144] Initialize the intermediate variable i=1;

[0145] Gas[i]LastStepFlow=0; / / The gas path flow value of the previous process step of this process step is 0

[0146] Gas[i]StepFlow=0. / / In this process step, the flow rate value of the gas path is 0

[0147] In order to carry out cyclic inspection on the gas path and set the flow rate of each gas path in the future, and then read the flow value of each gas path in the process table.

[0148] Such as Figure 4 As shown, i is an intermediate variable through which each gas path is traversed. For the process list in Table 1, there are 5 gas paths in total. When i is greater than 5, the step waiting time t is executed; The flow rate value of the gas path in the secondary process step;

[0149] What needs to be explained here is that in this example, it is a cyclic inspecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com