Contact spring and brush contact element applying same

A technology of contact reeds and contacts, applied in the direction of electrical components, circuits, connections, etc., can solve problems such as waste of materials, rising costs, failure of electrical connectors, etc., and achieve the effect of improving transmission power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

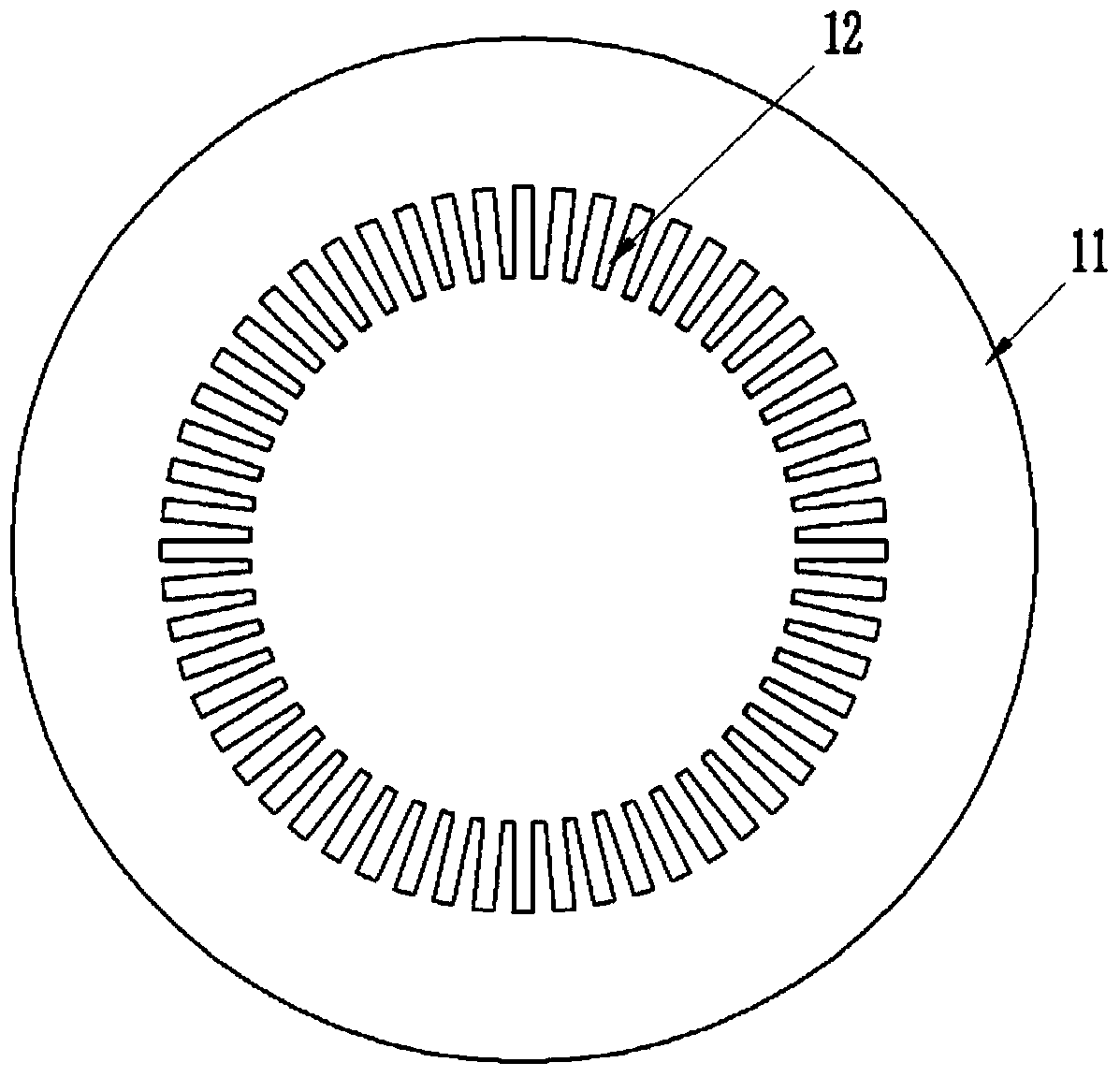

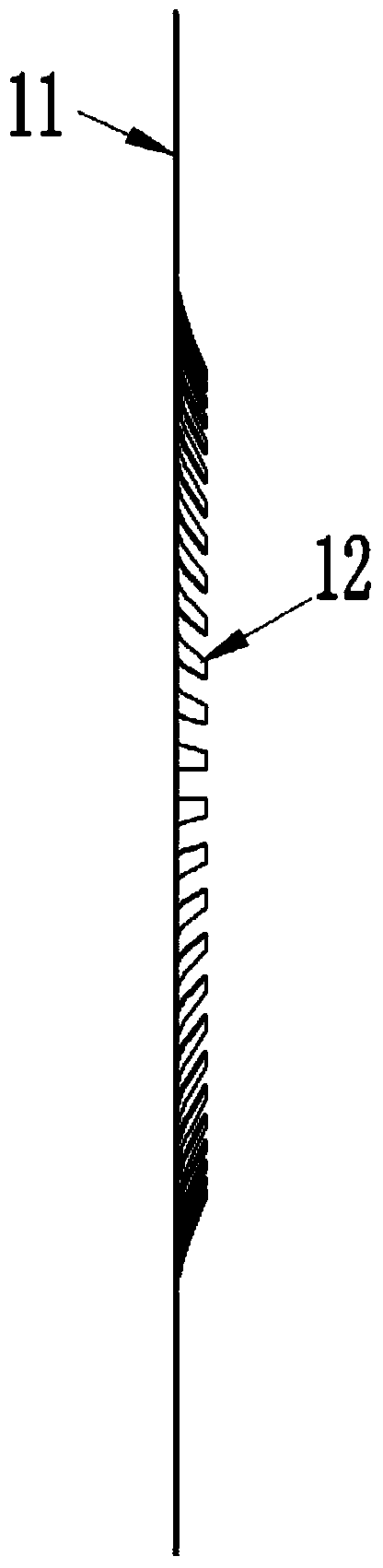

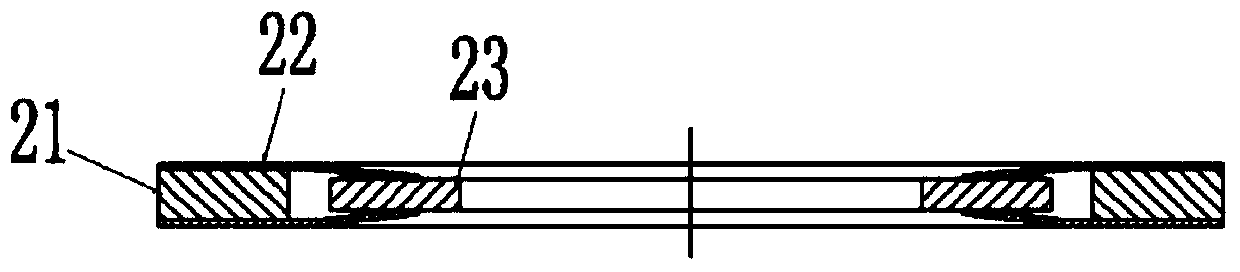

[0020] Examples of contact reeds, such as Figure 1-2 As shown, the contact reed includes a female ring 11. In this embodiment, the female ring 11 is a circular ring made of copper, and a cantilevered elastic contact finger 12 is arranged inside it. The elastic contact finger 12 wraps around the female ring 11. The center line of the center line is evenly arranged. In this embodiment, the elastic contact fingers 12 and the female ring 11 are of an integrated structure, which is formed by punching. Each elastic contact finger 12 includes a fixed end located on the female ring 11 and gradually The contact end close to the center line of the female ring, the contact end of the elastic contact finger 12 gradually shifts to one side of the female ring 11 and protrudes from the corresponding side of the female ring 11 in the process of moving closer to the center line of the female ring 11, In addition, each elastic contact finger 12 in this embodiment is tapered gradually from its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com