Rotary conducting mechanism and rotary electrical coupler with same

An electrical connector and conductive ring technology, which is applied in the field of rotating electrical connectors, can solve the problems of electrical connector failure, increased electrical connector axial size, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

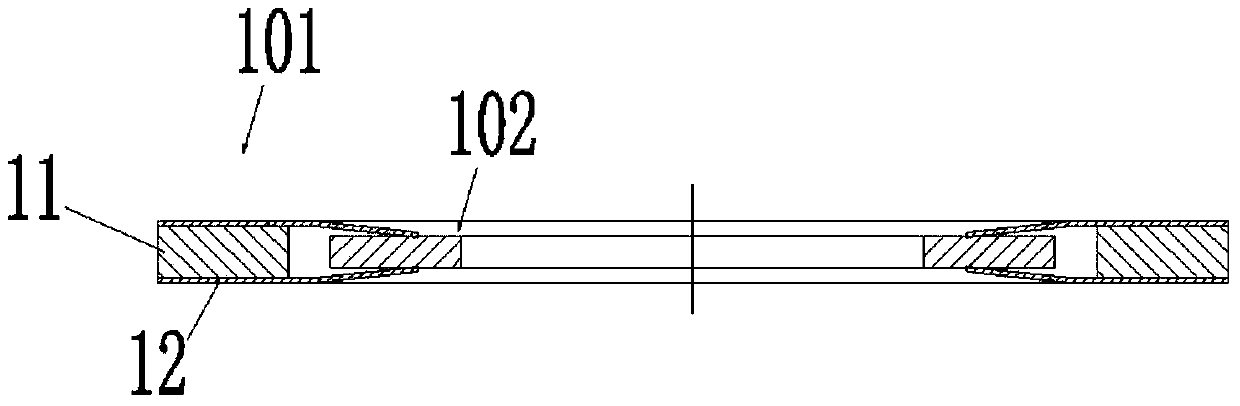

[0022] Examples of rotating conductive mechanisms, such as Figure 1-3 As shown, the rotating conductive mechanism includes an electric brush contact 101 and an electric slip ring 102.

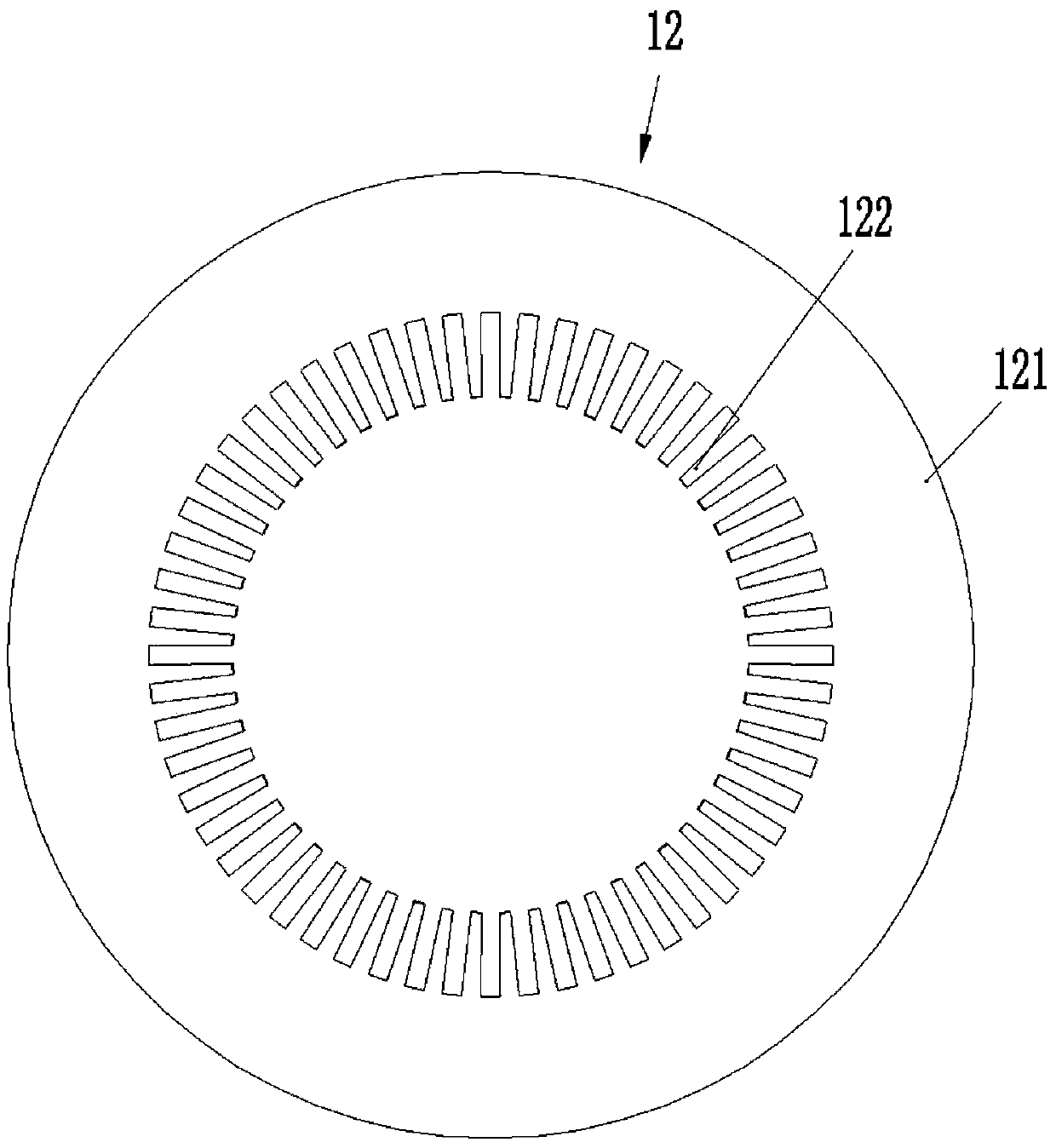

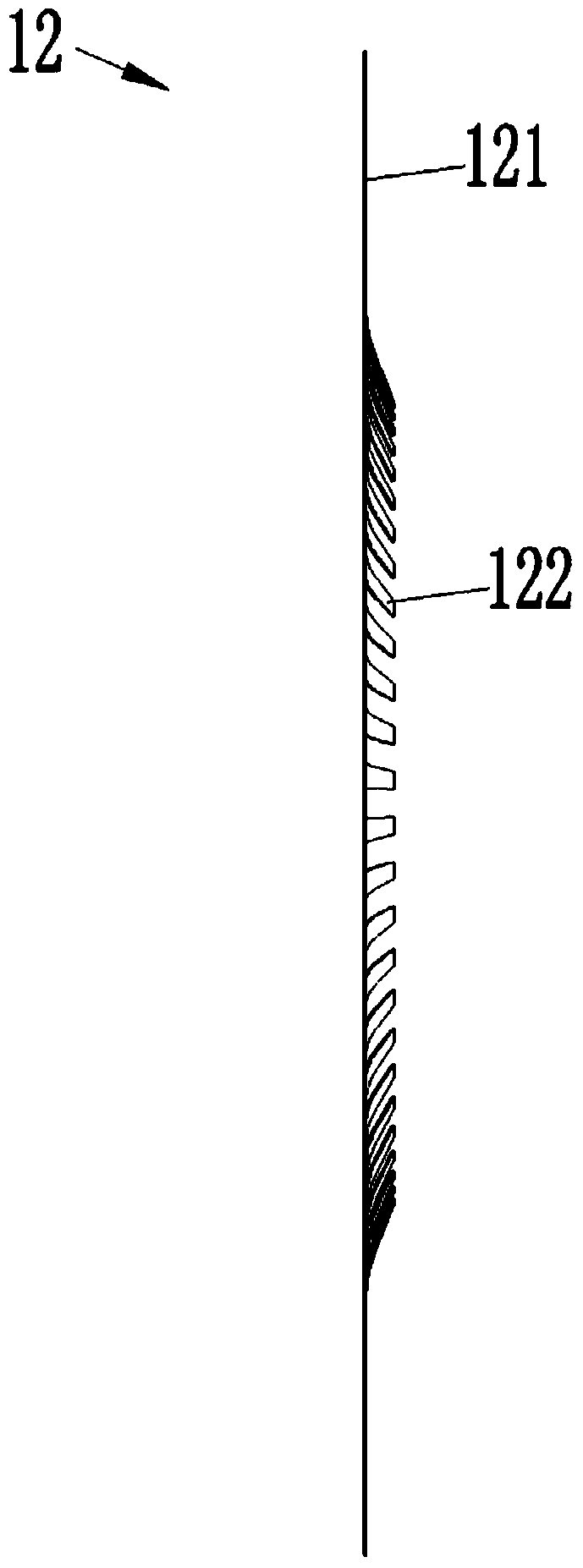

[0023] The brush contact 101 includes a conductive ring 11 and a contact spring 12, and the conductive ring 11 and the electric slip ring 102 are coaxially sleeved on the electric slip ring 102. In this embodiment, contact springs 12 are attached to the two axial sides of the conductive ring 11 respectively. Each contact spring 12 includes a mother ring 121. In this embodiment, the mother ring 121 is a circular ring and is made of copper. A circle of cantilevered elastic contact fingers 122 are provided on the inner side of the mother ring 121. The elastic contact fingers 122 surround the mother ring 121. In this embodiment, the elastic contact fingers 122 and the mother ring 121 are an integral structure, which is formed by punching. Each elastic contact finger 122 includes a fixed end on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com