Washing pump for automobile windscreen wipers

A technology for washing pumps and automobiles, applied in the field of washing pumps, can solve problems such as cumbersome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions and other beneficial effects of the present invention will be apparent through the detailed description of specific embodiments of the present invention below in conjunction with the accompanying drawings. The drawings are provided for reference and illustration only, and are not intended to limit the present invention. The dimensions shown in the drawings are only for the convenience of clear description, and do not limit the proportional relationship.

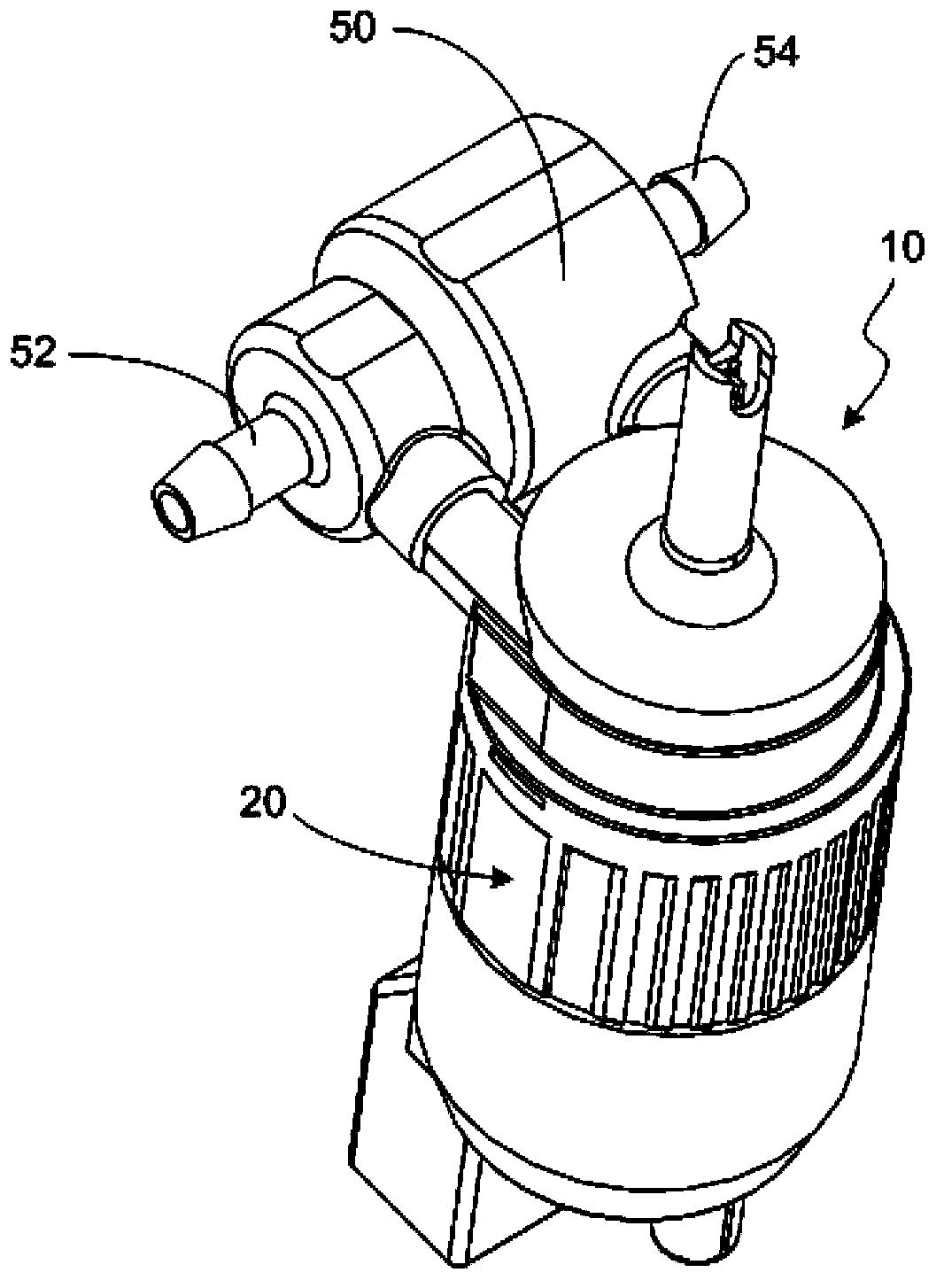

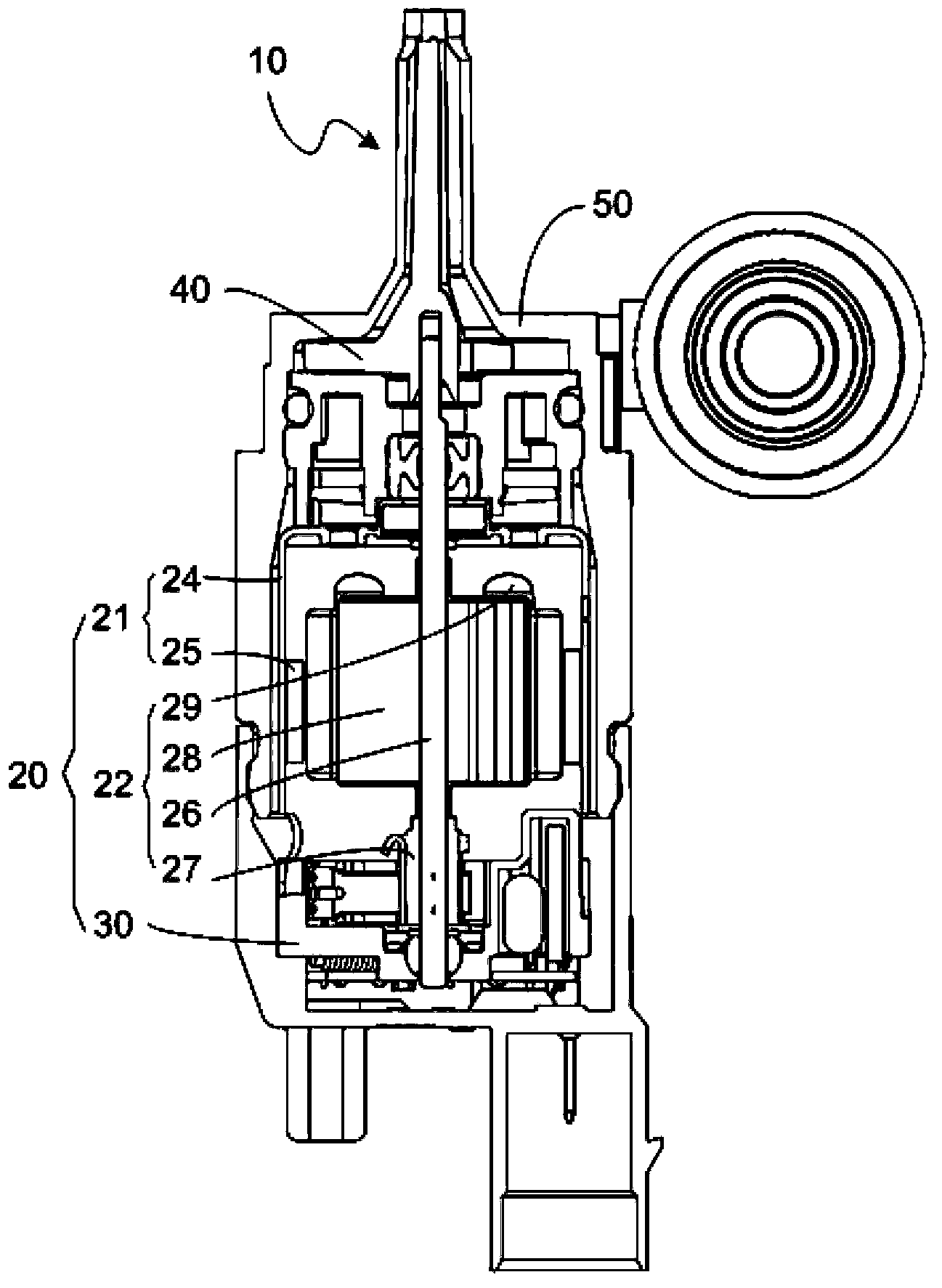

[0023] see figure 1 and figure 2 The washing pump 10 according to the preferred embodiment of the present invention includes a motor 20, an impeller 40 connected to the motor 20 and driven by it, and a pump casing 50 fixed to the motor 20 and housing the impeller 40 therein. The pump housing 50 has an inlet 52 which leads to a container containing water or detergent and an outlet 54 for delivering said water or detergent. When the motor 20 works, it drives the impeller 40 to rotate, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com