Permanent magnet coreless brushless motor

A brushless motor, ironless technology, applied in synchronous motors with static armatures and rotating magnets, etc., can solve the problems of high motor starting current, consumption of silicon steel sheets, poor energy saving effect, etc., and achieve low operating noise. , The effect of reducing weight and calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

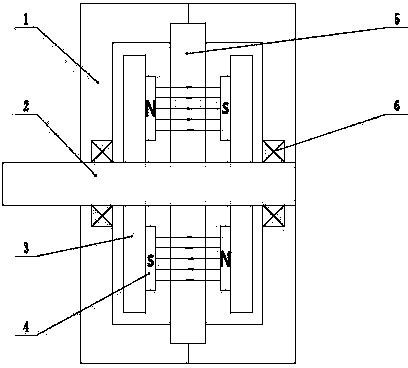

[0013] Such as figure 1 As shown, a permanent magnet ironless brushless motor includes a casing 1, a stator and a rotor set on the main shaft 2, the stator is composed of an armature winding disk 5 with an ironless structure, and the rotor is It consists of two yokes 3 with several fan-shaped magnets 4 arranged on them. The two yokes 3 and the armature winding disk 5 are both disk-shaped structures. The two yokes 3 are respectively located on the left and right of the armature winding disk 5 on the main shaft 2 On the right side, and the two yokes 3 are parallel to the disk surface of the armature winding disk 5, the air gap magnetic density between the armature winding disk 5 and the yoke 3 on both sides is equal, and the magnets 4 on the two yokes are one by one Relatively, the magnetic poles of the magnets 4 are opposite to each other, and an axial magnetic field is formed between the magnets on the two yokes 3. Several magnets 4 on each yoke are arranged evenly along the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com