Sunken type soft and hard combined circuit board and manufacturing method thereof

A soft-rigid combination and manufacturing method technology, applied in the direction of multilayer circuit manufacturing, printed circuit components, printed circuit structural connection, etc., can solve the problem that the thickness of the camera chip cannot be reduced, and can no longer be reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

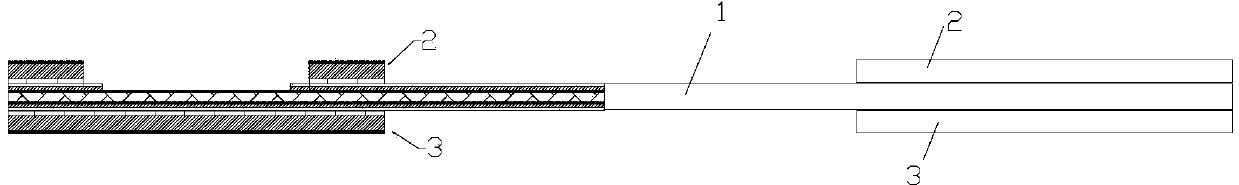

[0049] Step 1: Make the inner soft board of the soft-hard board

[0050] (1) Cutting

[0051] The Dsflex600122512R P double-sided adhesive-free calendered copper coil material from Doosan, South Korea is used as the raw material of the flexible board, and the copper clad laminate consists of three layers: copper foil layer 12 on the soft board, PI layer 13 on the soft board, and copper foil layer under the soft board. 14. Use a cutting machine to cut it into sheets with a size of 250*190mm. The thickness of the copper foil layer 12 on the flexible board and the copper foil layer 14 under the flexible board are both 12um, and the PI layer 13 of the flexible board in the middle is 25um.

[0052] (2) Dry film, exposure, development, etching and film withdrawal; detection

[0053] On the upper surface of the copper foil layer 12 on the soft board of the described copper clad board and the lower surface of the lower copper foil layer 14 of the soft board, dry films are pasted wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com