Structure of on-line appearance detector and detection method thereof

A detection method and detection machine technology, applied in the direction of measuring devices, optical testing of flaws/defects, material analysis through optical means, etc., can solve the problem that the shooting speed and detection time cannot meet the production line speed, human error, product detection is time-consuming and laborious and other issues, to achieve the effect of eye protection, adjustable brightness, and favorable recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will describe in detail with reference to the accompanying drawings in conjunction with the embodiments, so as to further explain the technical features and advantages of the present invention.

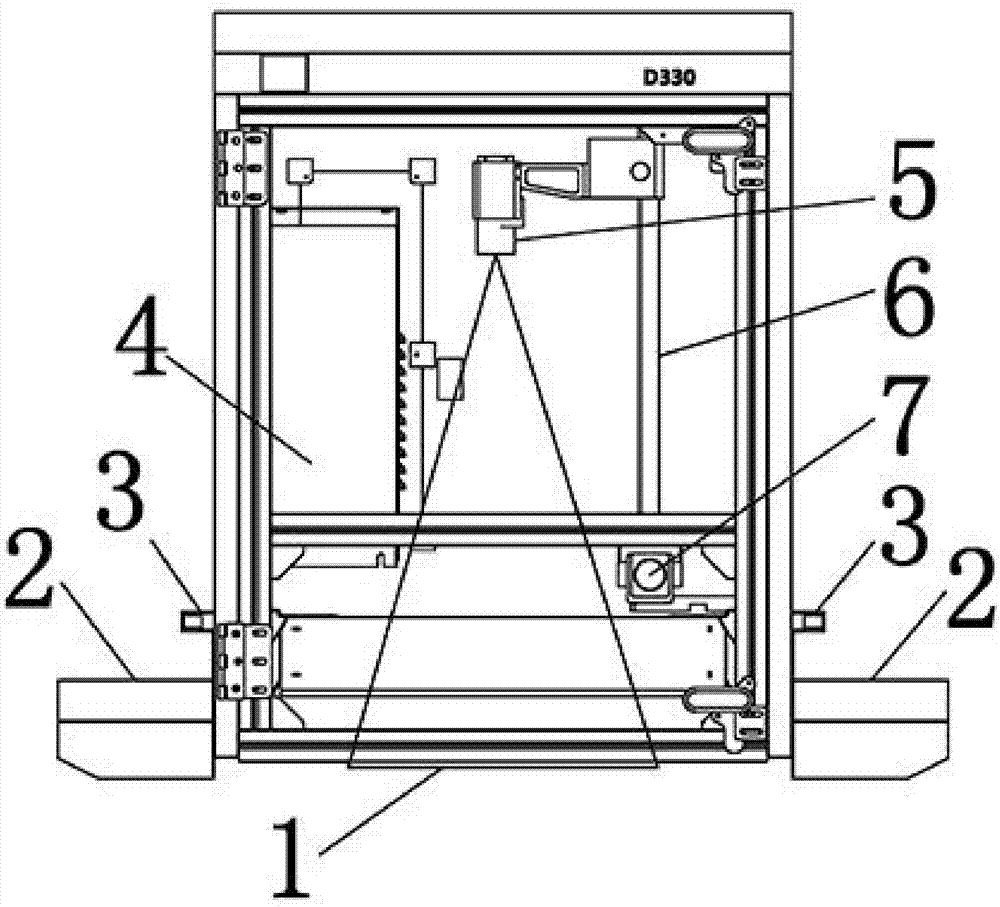

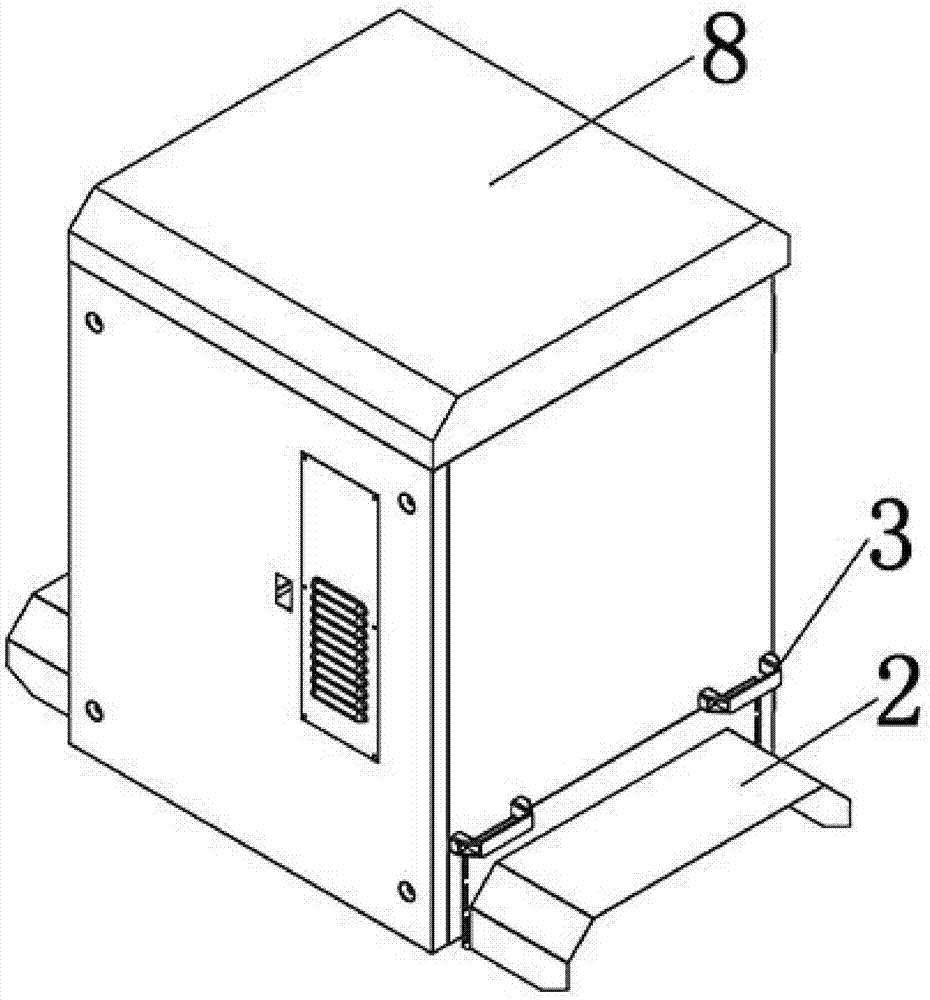

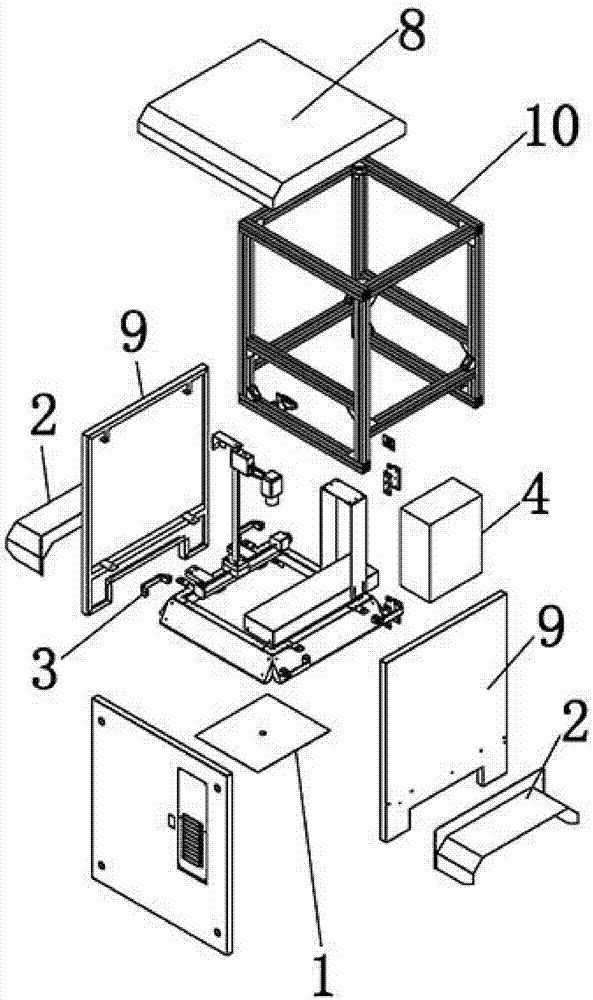

[0030] like Figure 1-5 As shown, the structure and detection method of an online appearance inspection machine of the present invention, the structure of the inspection machine includes a base 15, a complete machine frame 10 installed on the base 15, and an upper cover plate arranged on the complete machine frame 10 8 and the side cover 9, the side cover 9 is equipped with a visor 2 and a handle 3, the inside of the base 15 is provided with a light source 14, the light source 14 is installed in the diffusion cover, and the light source 14 is an LED light bar, The number of the light source 14 and the diffusion cover are both 4; the Y-axis screw rod 7 is installed on the base 15, the Y-axis screw rod 7 is provided with a screw rod mounting seat 12, and the Z-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com