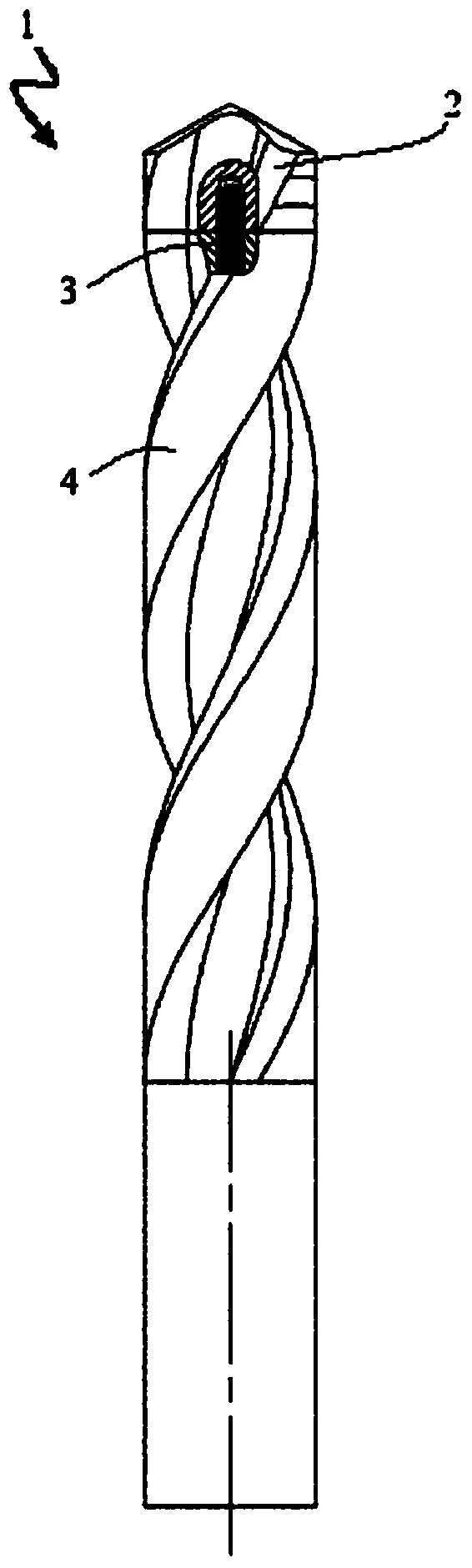

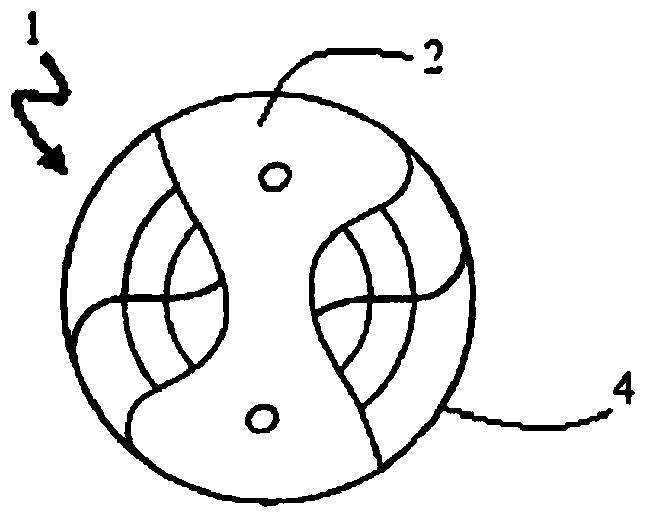

Hard-material threaded connection

A hard material, threaded connection technology, applied in the direction of connection, rod connection, connection components, etc., can solve problems such as thread failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

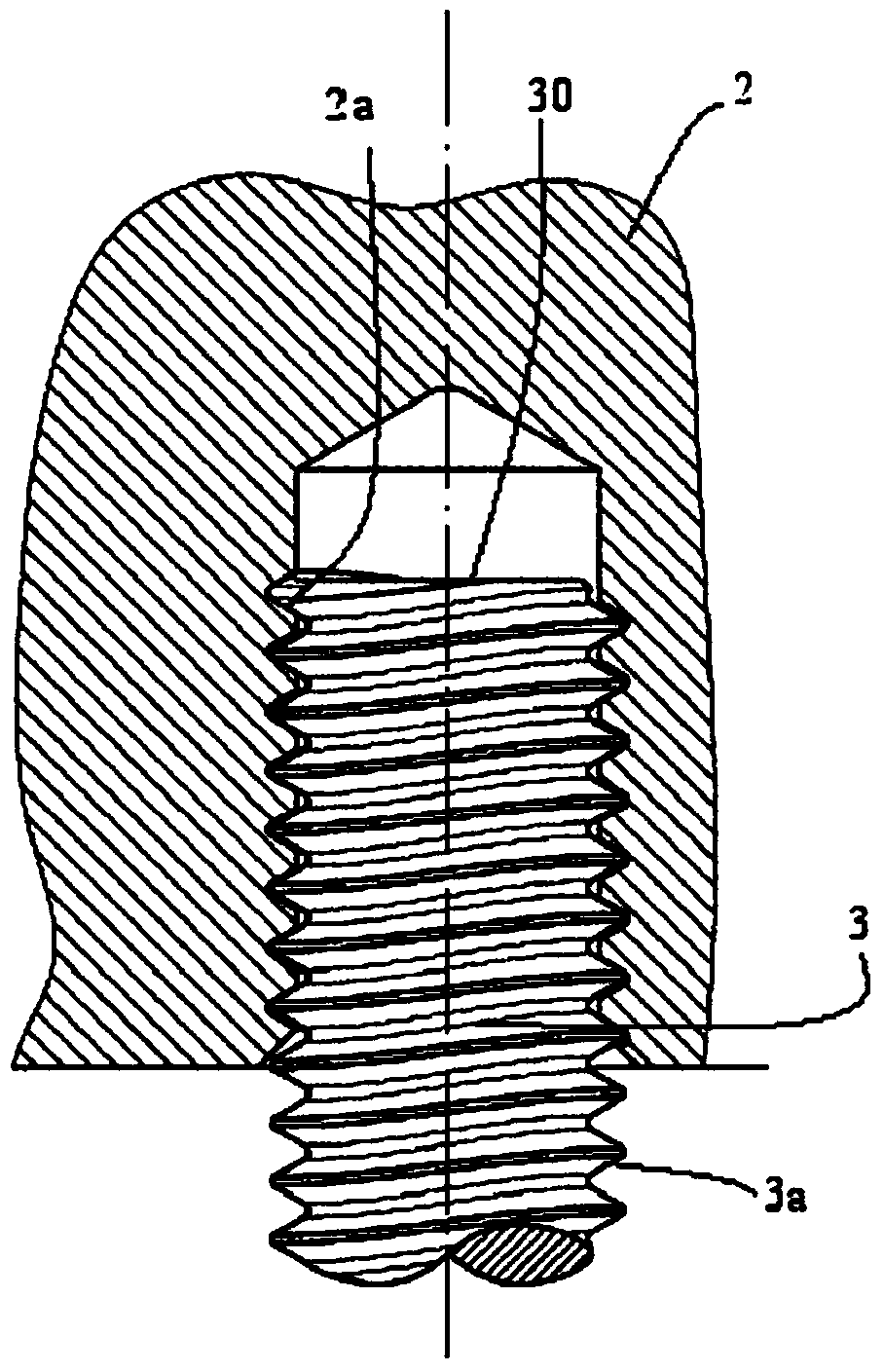

[0051] Experiments were carried out in which internal threads with different pitches were formed in each case in substantially cylindrical structural parts made of hard material, to be precise hard metal, by means of a helical milling method.

[0052] In each case, the screw connections were produced by means of steel screws (phosphating 8.8 screw quality) with a metric M6 ISO thread (pitch 1.000 mm) and a thread depth of 15 mm. The yield strength of the screw reached a tensile force of 12864N and fracture occurred at 16080N.

[0053] In sample 1, an unmodified M6ISO thread (pitch 1.000 mm) was formed in hard material.

[0054] In Sample 2, an M6 thread having a pitch increased by 1% (pitch 1.010 mm) compared to the standard thread was formed in a hard material.

[0055] In Sample 3, an M6 thread having a pitch increased by 2% (pitch 1.020 mm) compared to the standard thread was formed in a hard material.

[0056] In Sample 4, an M6 thread with a pitch increased by 3% (pitch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com